Asphalt spraying and conveying device with cleaning function

A conveying device and asphalt technology, which is applied in roads, road repairs, roads, etc., can solve the problems of high diesel consumption and high use cost, and achieve the effects of reducing operation intensity, low use cost and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

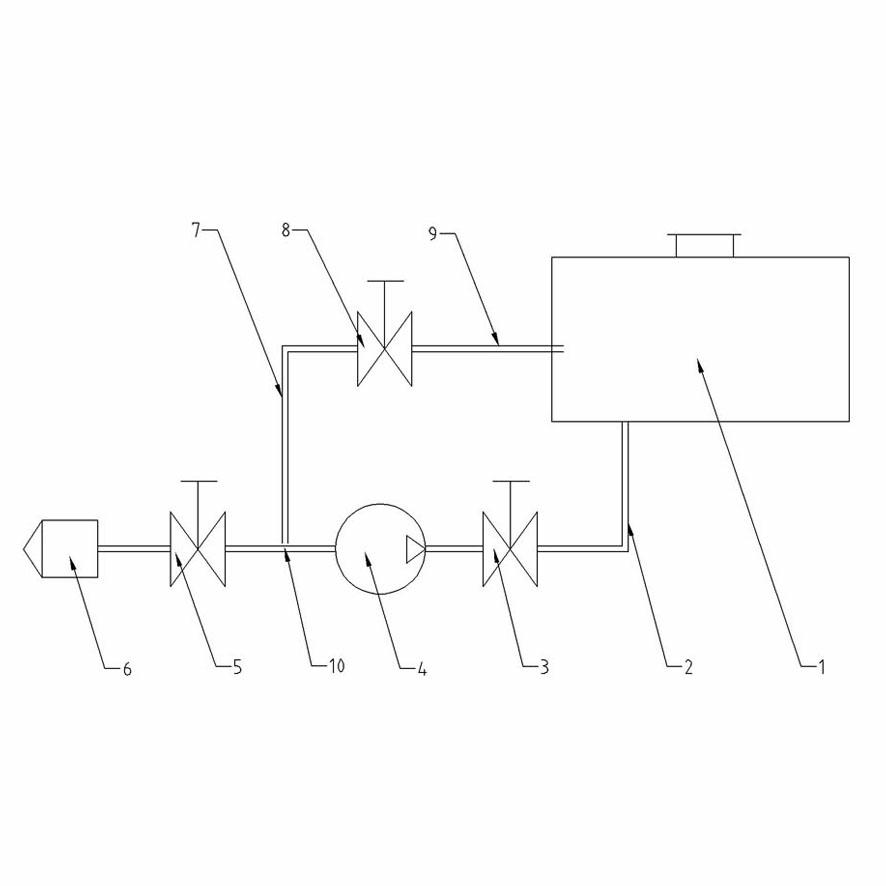

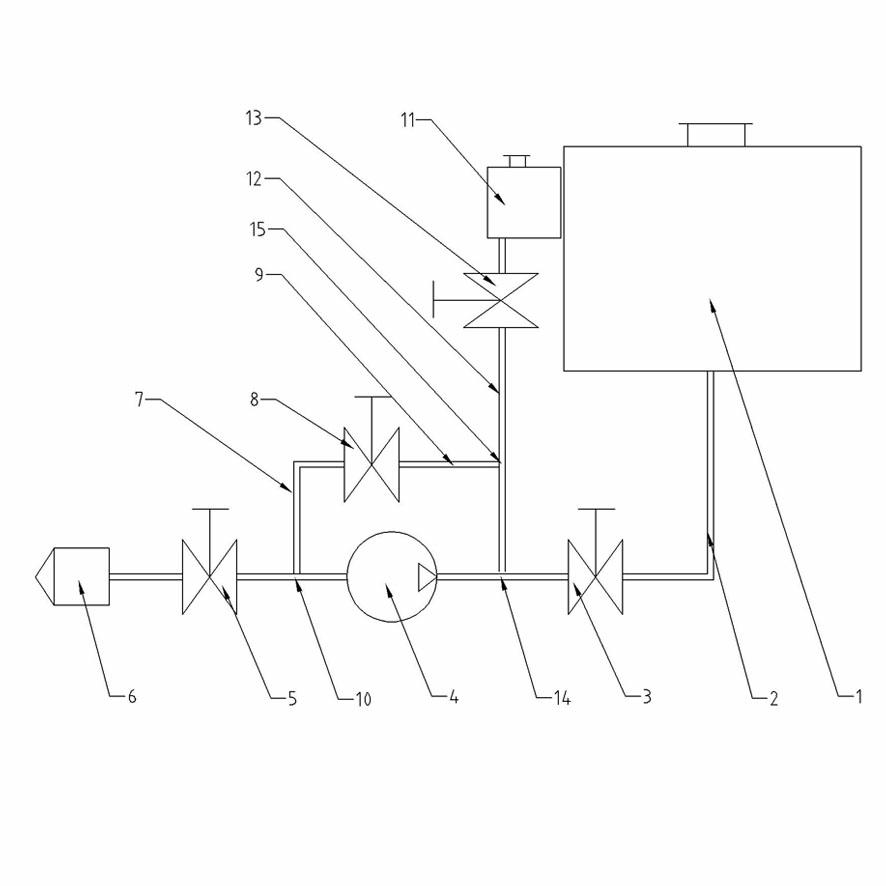

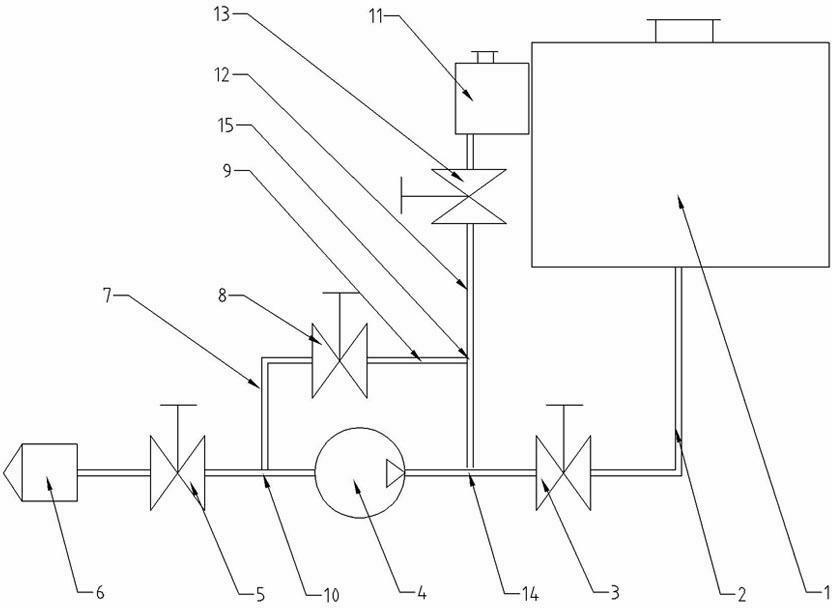

[0011] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail:

[0012] exist figure 2 Among them, an asphalt spray conveying device with cleaning, including hot asphalt tank 1, asphalt delivery stop valve 3, asphalt pump 4, asphalt spray stop valve 5, asphalt nozzle 6, oil return stop valve 8, diesel tank 11 and diesel stop valve Valve 13; the hot asphalt tank 1 is connected to the joint of the second three-way pipe 14 through the oil suction pipe 2 through the asphalt delivery shut-off valve 3, the outlet of the second three-way pipe 14 is connected to the input end of the asphalt pump 4, and the outlet of the asphalt pump 4 The output is connected to the asphalt nozzle 6 through the first three-way 10, the asphalt spray cut-off valve 5; the asphalt pump 4 and the oil return stop valve 8 are connected to the first oil return pipe 7, the second oil return pipe 9, and the first three-way 10, The second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com