Metal mesh box revetment structure of earth-rock dam and construction method of metal mesh box revetment structure

A technology of metal mesh and earth-rock dams, applied in the direction of coastline protection, etc., can solve problems such as poor erosion resistance or pan erosion or seismic performance, high requirements for particle size and regularity, and inconvenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

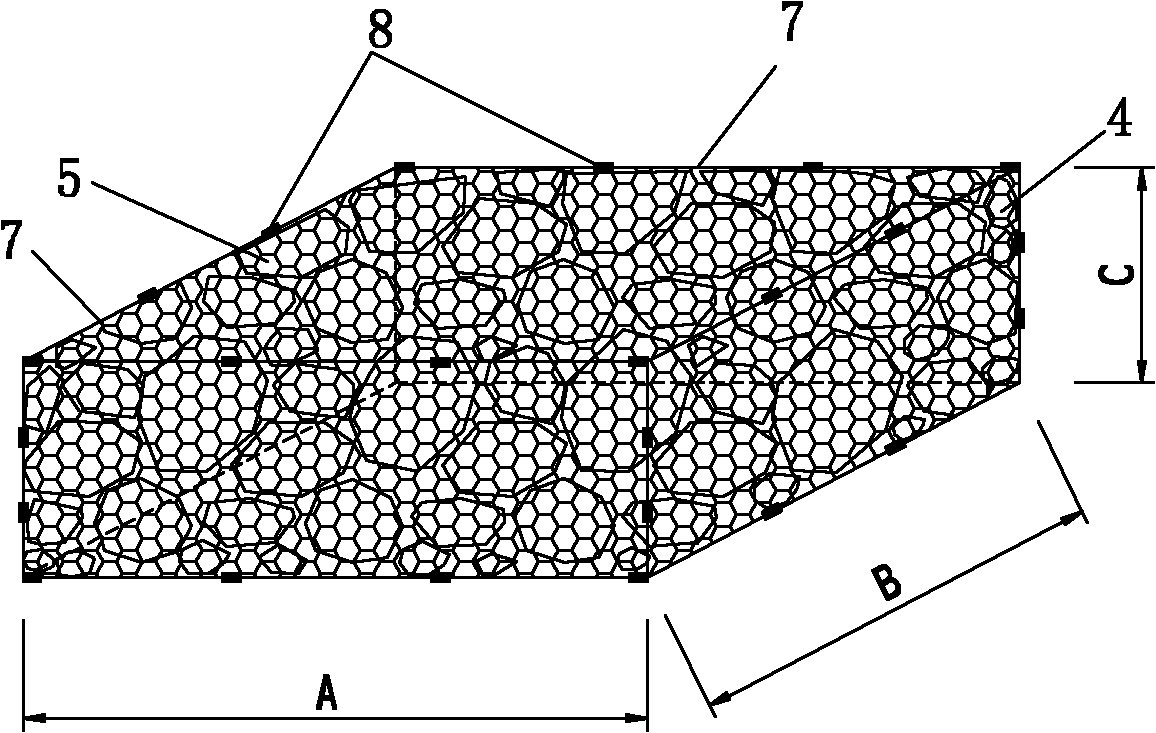

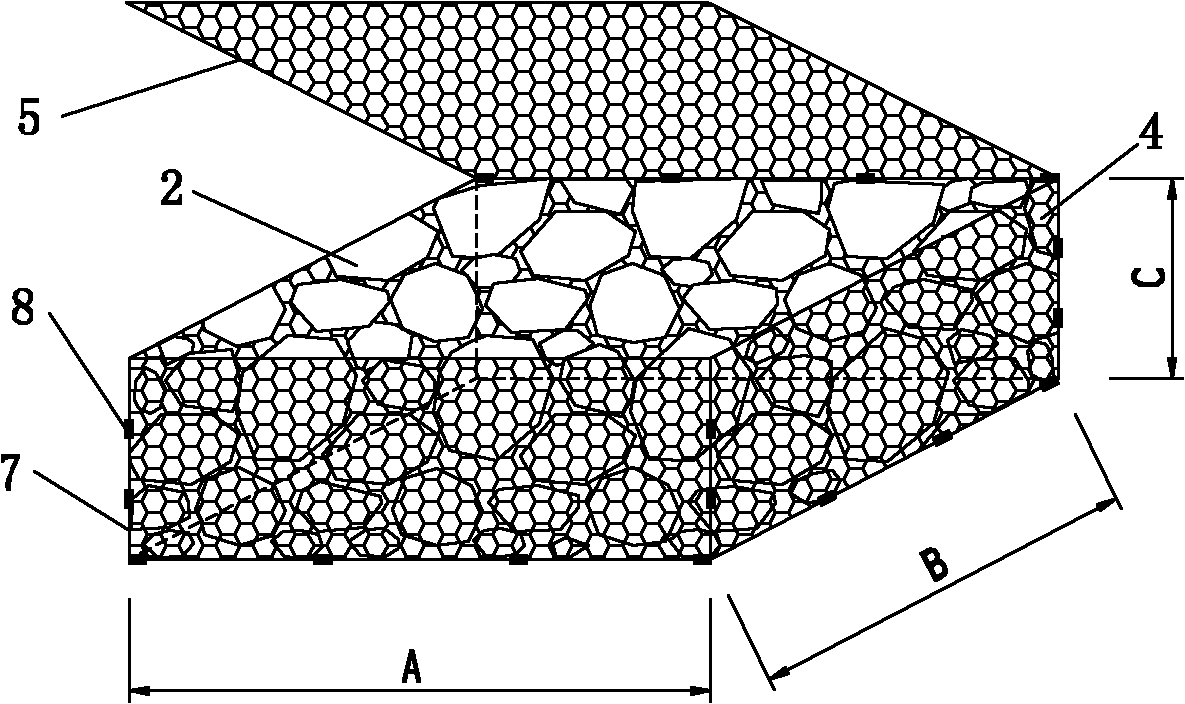

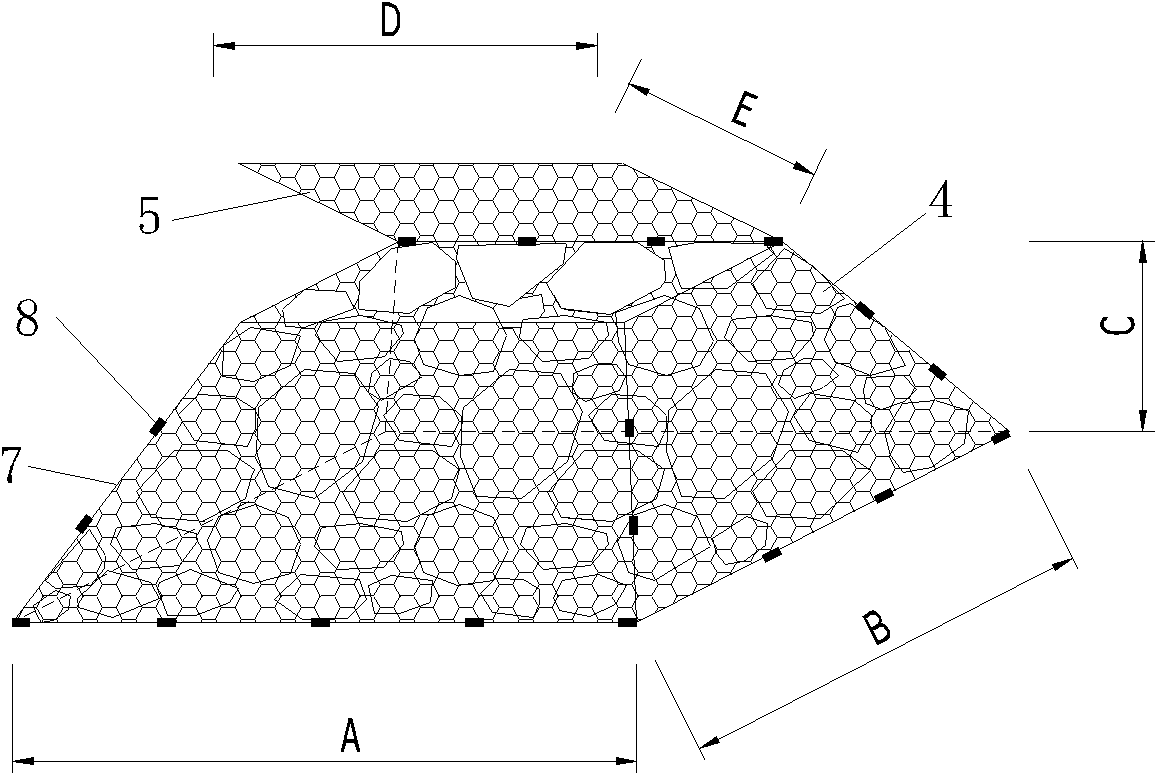

[0140] Such as figure 1 , 2 7. As shown in 7, a metal mesh box slope protection structure for earth-rock dams is composed of box 1 and stone 2, and stone 2 is filled in box 1;

[0141] Such as Figure 5 , 6 As shown, the basic material of the box body 1 is a high-strength metal mesh wire 6, a supporting edge 7, and a tie wire 8, which have been treated with rust prevention. The mesh wire 6 is twisted into a knot by a single twist or a double twist or multiple twists and added with a supporting edge 7 to form a box. The bottom surface of the body 3, the side surface of the box body 4, the mesh sheet of the box body cover 5, multiple mesh sheets are assembled into a metal mesh box with anti-rust function, such as figure 1 , 2 , 3 and 4;

[0142] Such as figure 2 , 3 As shown, the structure of the box 1 can be a quadrangular structure, the height C is in the range of 10 cm to 200 cm, the length A is in the range of 10 cm to 300 cm, the width B is in the range of 10 cm to 300 cm, and t...

Embodiment 2

[0176] The construction method of the metal mesh box slope protection structure of earth-rock dam according to the present invention:

[0177] It is basically the same as Example 1, except that:

[0178] Step 1: Such as Figure 13 As shown, in accordance with the requirements of the industry standard "Design Code for Rolled Earth Dams", determine the location and area of the slope protection against wave erosion in the downstream tailwater level variable amplitude zone of the core rockfill dam;

[0179] Step 8, the metal mesh box slope protection structure on both banks of the downstream face of the dam body is firmly connected to the bank slope; paved to the top elevation of the protection area, and firmly connected to other slope protection methods on the upper part;

[0180] The other steps of the downstream slope protection can be the same as in Example 1.

Embodiment 3

[0182] The construction method of the metal mesh box slope protection structure of the earth-rock dam according to the present invention: the upstream slope protection step can be the same as the first embodiment; the downstream slope protection step can be the same as the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com