Bottom-columned surface-hole cast-in-place greening concrete and method and equipment for production thereof

A technology of greening concrete and concrete, which is applied in excavation, climate change adaptation, molds, etc., can solve the problems of unfavorable plant growth and lack of greening function, and achieve the effect of high void ratio, good equipment performance and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

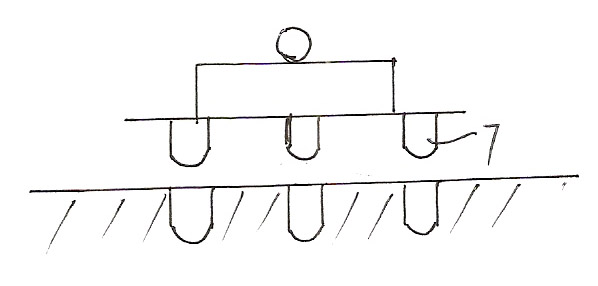

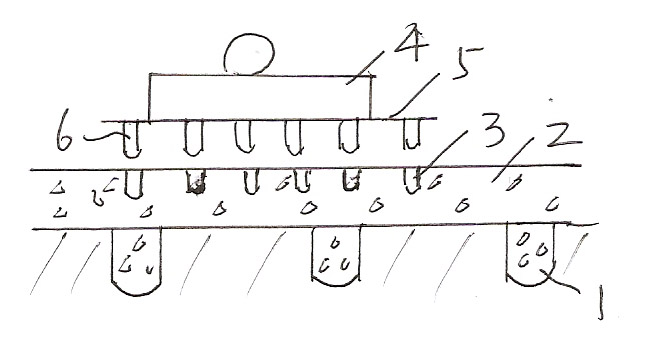

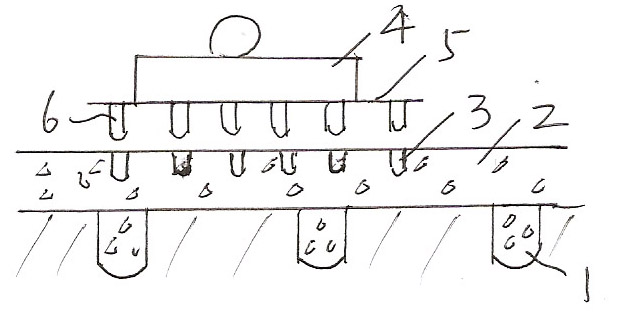

[0025] A method for preparing cast-in-place greening concrete with surface holes on bottom columns, comprising the following steps:

[0026] (1) Mold making: level the construction surface, and use punching equipment to form multiple concave molds on the surface of the construction surface; the punching equipment can use vibration and pressure control equipment with columnar protrusions 7 .

[0027] (2) Laying: Lay the mixed concrete on the construction surface, a part of the concrete enters the die to form a concrete column 1, and the other part of the concrete forms a concrete layer 2 covering the surface of the construction surface;

[0028] (3) Vibration suppression: Use a vibrator with multiple vertical mold rods on the pressure plate to vibrate and suppress to form the cast-in-place greening concrete with the surface hole of the bottom column.

[0029] Concrete consists of the following components by weight:

[0030] Stones 400~500 parts

[0031] Cement 100~200 parts ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com