Elastic metal slider support

A metal and skateboard technology, used in building components, shockproof, construction, etc., can solve the problems of rubber aging, rubber materials cannot withstand high temperature, and cannot guarantee service life, etc., and achieve long-term stable performance and high vertical bearing capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

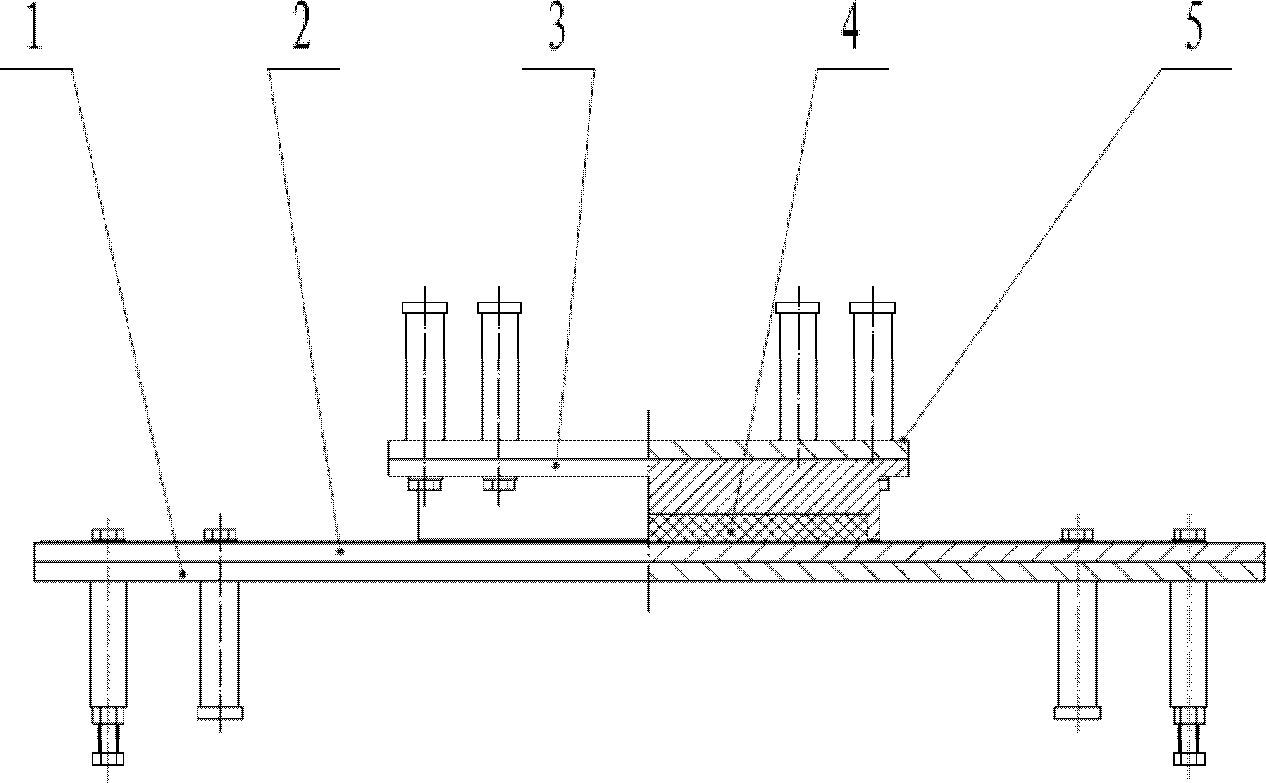

[0022] A metal elastic skateboard support, such as figure 1 As shown, it includes the lower embedded plate 1, the base 2, the upper embedded plate 5, the top plate 3 and the metal elastic layer 4, the lower embedded plate 1 is set at the bottom, and the base 2 is fixed on the upper surface of the lower embedded plate 1 by bolts , the upper embedded plate 5 is arranged on the uppermost layer, the top plate 3 is fixed on the lower surface of the upper embedded plate 5 by bolts, the bottom of the top plate 3 is provided with a groove, the metal elastic layer 4 is embedded in the groove, and placed on the base 2 above.

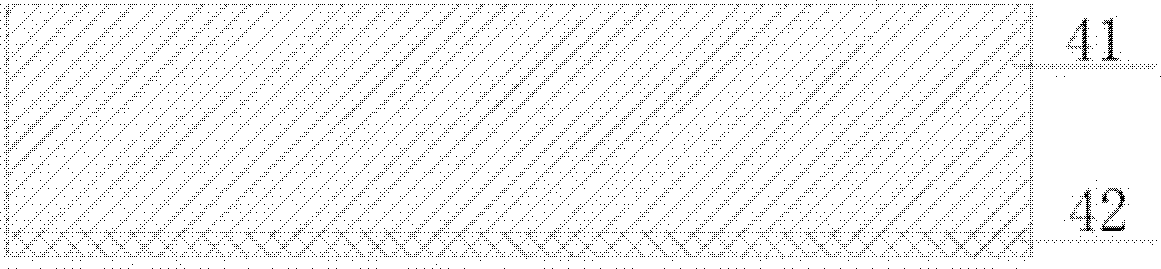

[0023] The lower embedded plate 1 is embedded in the lower concrete structure during installation, the base 2 is welded with a stainless steel plate, the upper embedded plate 5 is embedded in the upper concrete structure during installation, and the metal elastic layer 4 is composed of metal spring pads 41 and Polytetrafluoroethylene plastic layer 42 is formed, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com