Method for manufacturing reserved concrete hole of floor and mold

A technology of reserving openings and manufacturing methods, which is applied to the preparation of formwork/formwork/work frame, building components on site, construction, etc. It can solve the problems of easy positioning deviation, pollute the environment, waste materials, etc., and achieve convenient operation , Easy molding, material saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

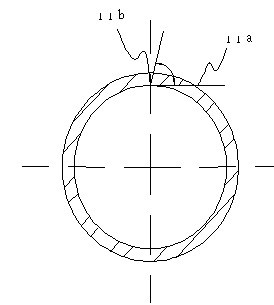

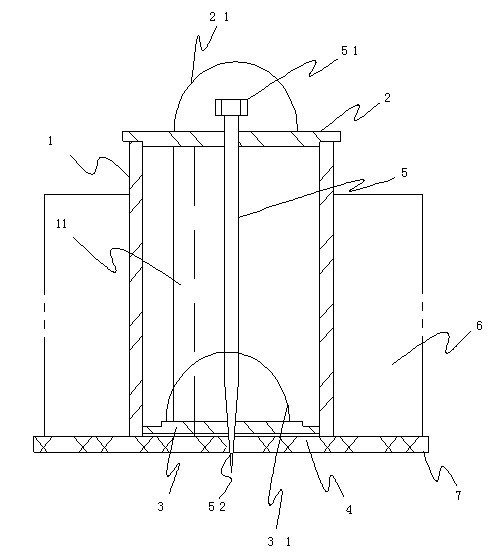

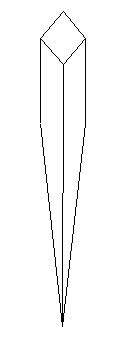

[0015] The invention discloses a method for making a reserved hole in floor concrete and a mold, which is composed of a mold cylinder 1, a cover plate 2, a support plate 3, and positioning nails 4. Take the preparation of a concrete hole with a minimum diameter of 143 mm as an example. PE mold cylinder 1, the thickness of the pipe wall is 5mm, and the height is 150mm. The mold cylinder runs through the slit along the vertical direction, and the surface of the slit is smooth. The angle between the line connecting the tangent points of the inner and outer walls of the slit and the extension line of the diameter of the inner wall tangent point 11b is 75 degrees. The diameter of the inner edge of the cover plate 2 is 136 mm, and the outer edge of the support plate is 133 mm. Lifting beams are arranged on the cover plate and the baffle. The positioning iron nail has a nut on its head, the length of the nail is 200mm, the diameter is 6mm, and the tip of the nail is angular.

[001...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com