Separated type fireproof sealing structure of fireproof door

A sealing structure and split-type technology, applied in the field of fire doors, can solve problems such as poor sealing effect and limited sealing area, and achieve the effect of easy implementation, good sealing effect and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The following examples are further explanations and illustrations of the present invention, and do not constitute any limitation to the present invention.

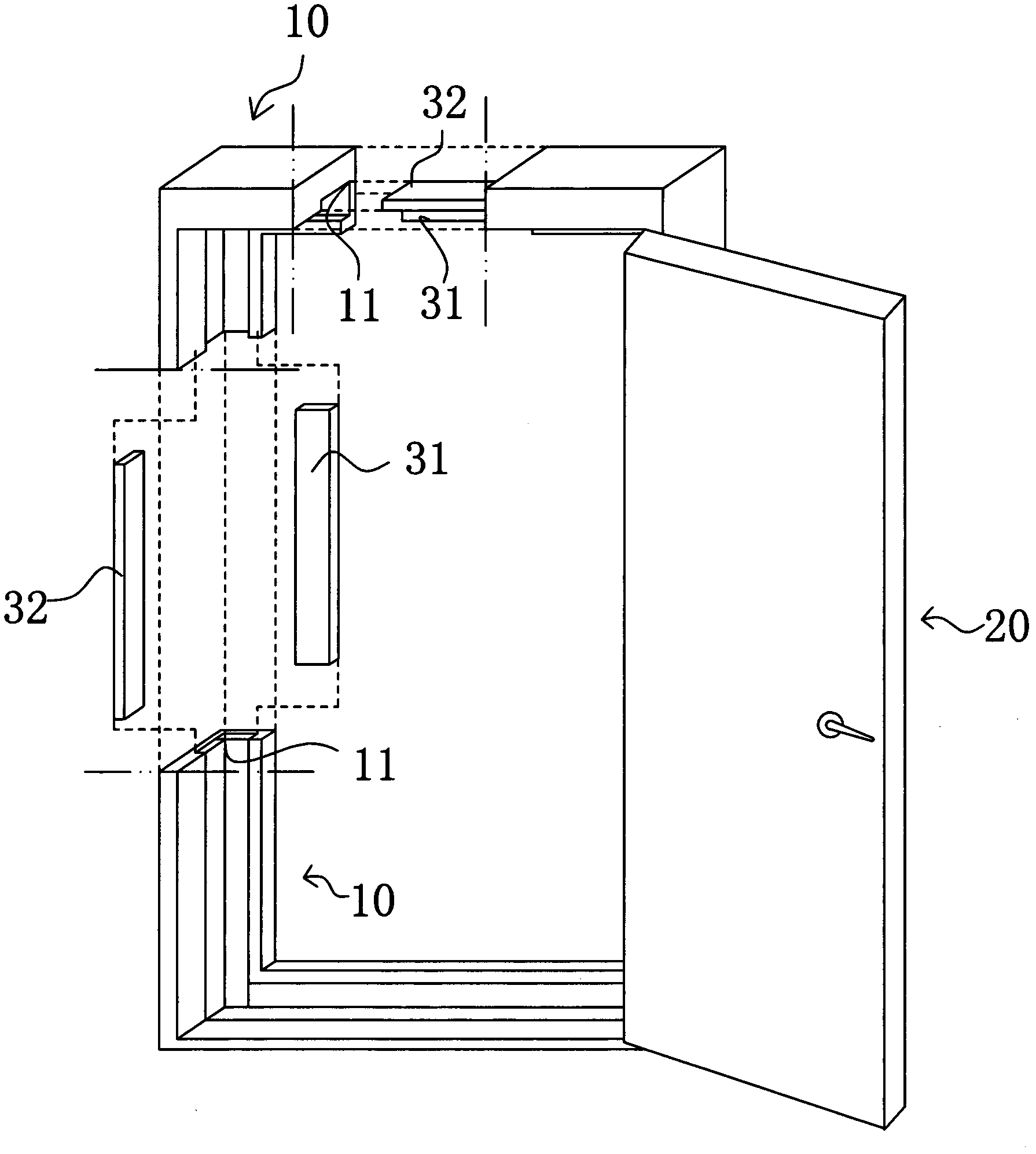

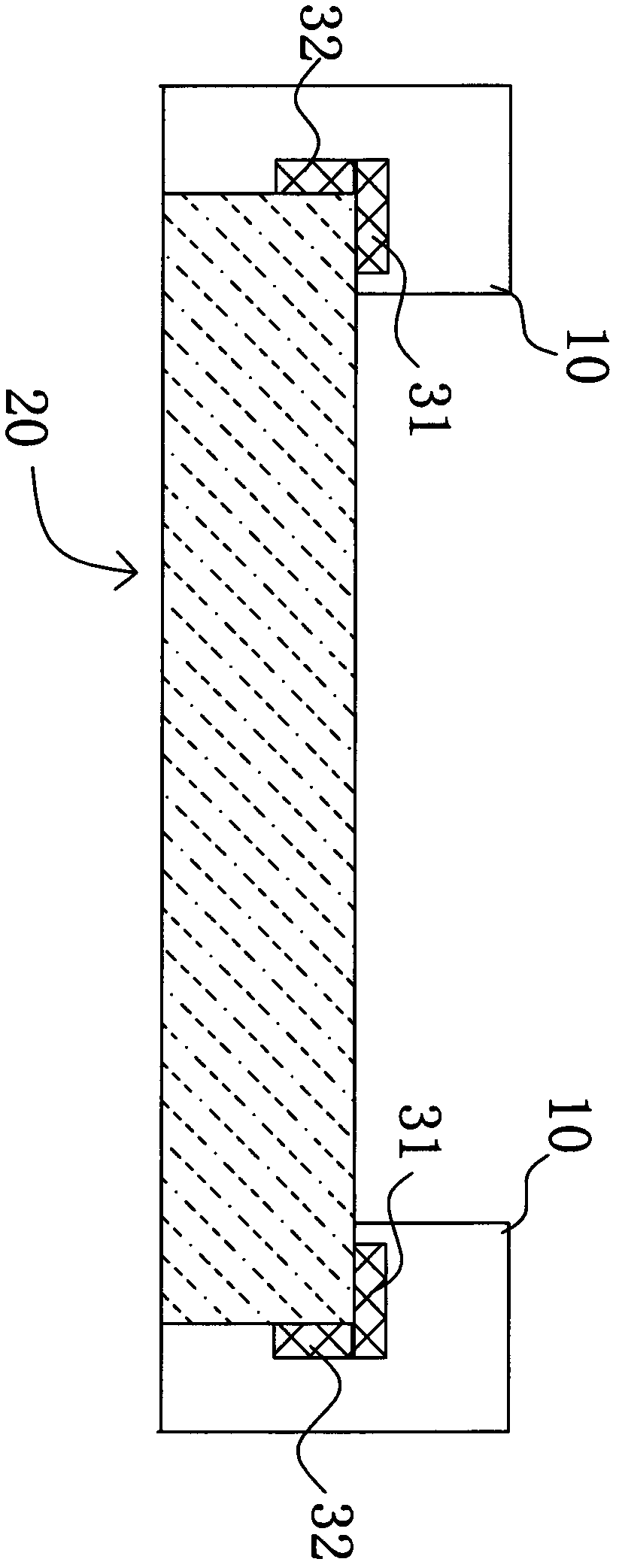

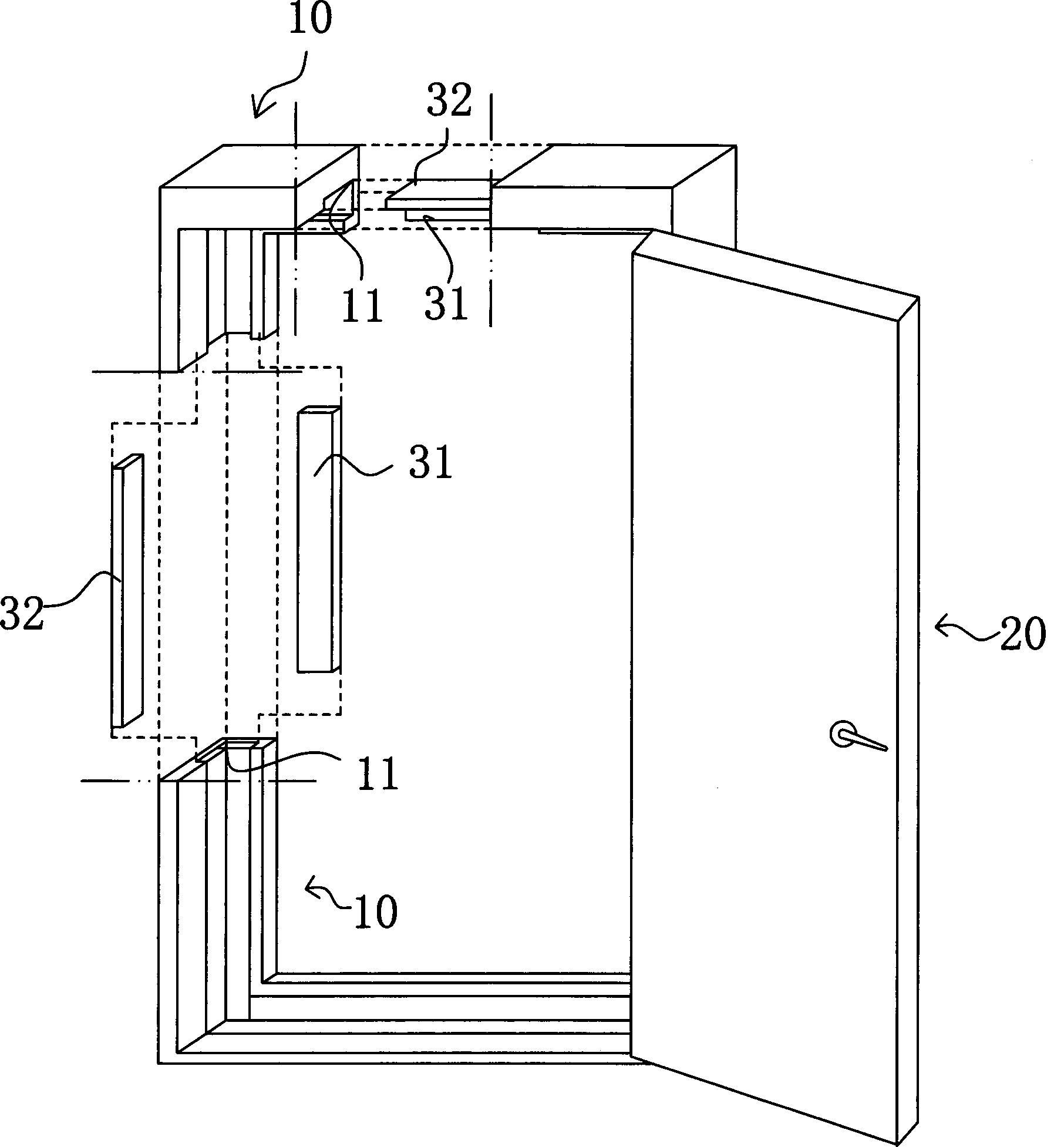

[0015] refer to figure 1 , figure 2 The split type fireproof sealing structure of the fireproof door of the present invention comprises a door frame 10, a door body 20 and a fireproof sealing strip 30. The present invention has no limitation on the structure of the doorframe 10 and the door body 20 of the fireproof door, which can be any known fireproof door Door frame and door body.

[0016] Such as figure 1 , figure 2 As shown, the inner and rear sides of the upper, lower, left and right four frames of the door frame 10 have two mutually perpendicular right-angled sides 11, forming stepped edges, and the right-angled sides 11 coincide with the periphery of the door body 10 touch.

[0017] The gist of the present invention is that a fireproof sealing strip 30 for fireproof sealing is provided on the right-an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com