Mine tunneller

A technology for roadheaders and mines, applied in cutting machinery, driving devices, earth-moving drilling and other directions, can solve the problems of falling casualties, operator poisoning, hypoxia and fainting, etc., to reduce accidents, production safety, and ingenious conception. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention relates to at least the following three preferred schemes for the supporting equipment for supporting the rotating platform, one is a jacking tower, the other is a rail car, and the third is a bulldozer. The structure of the installation is as follows:

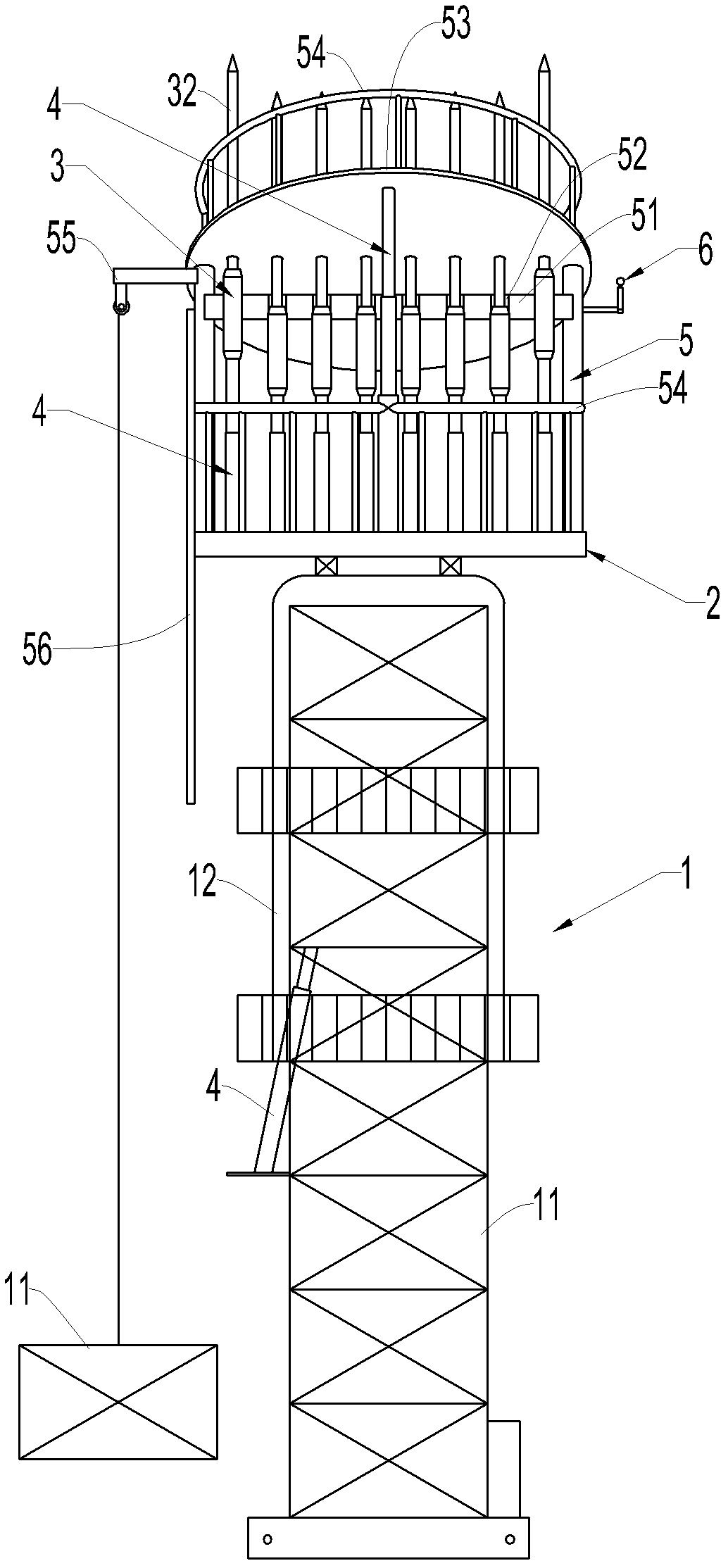

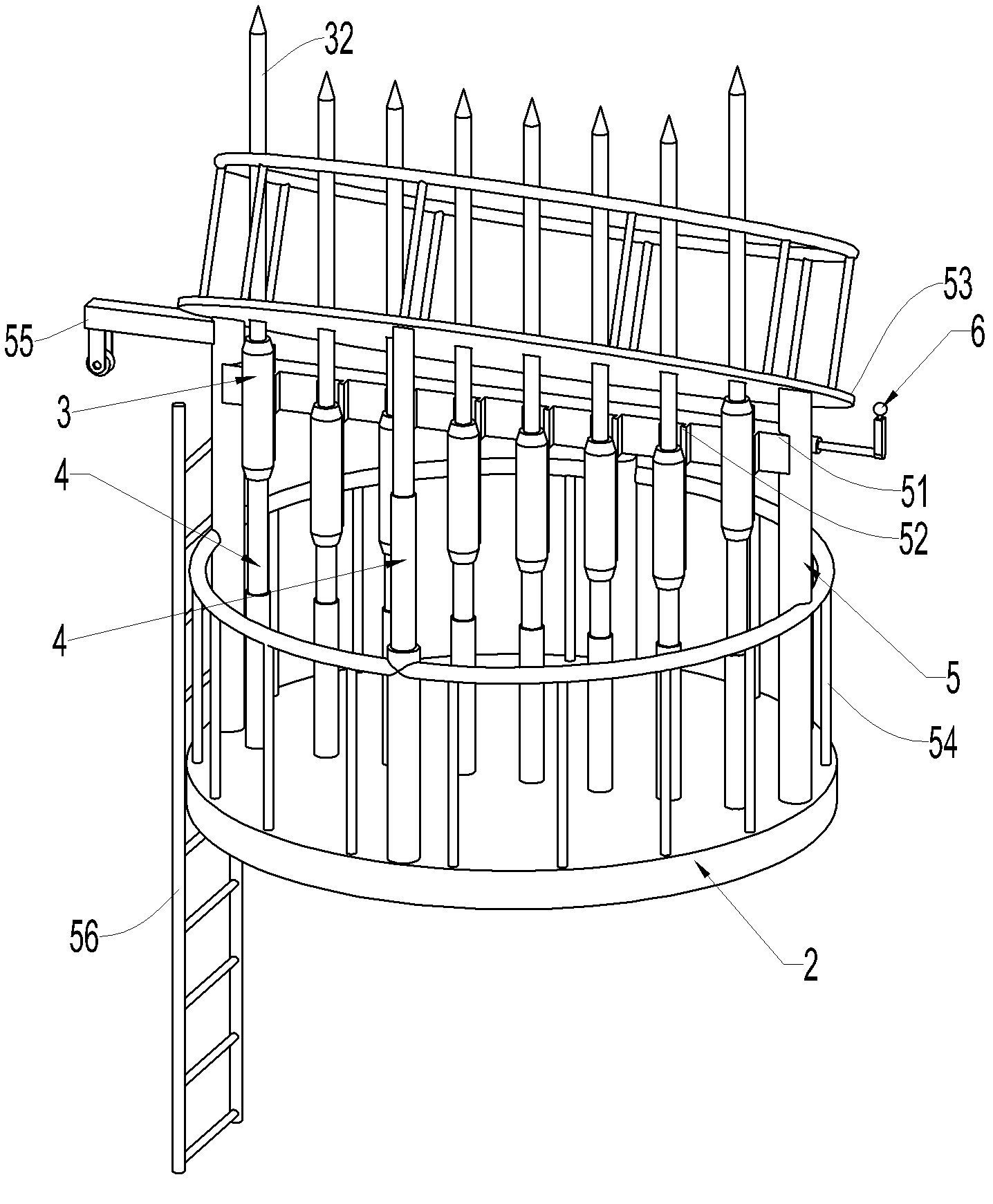

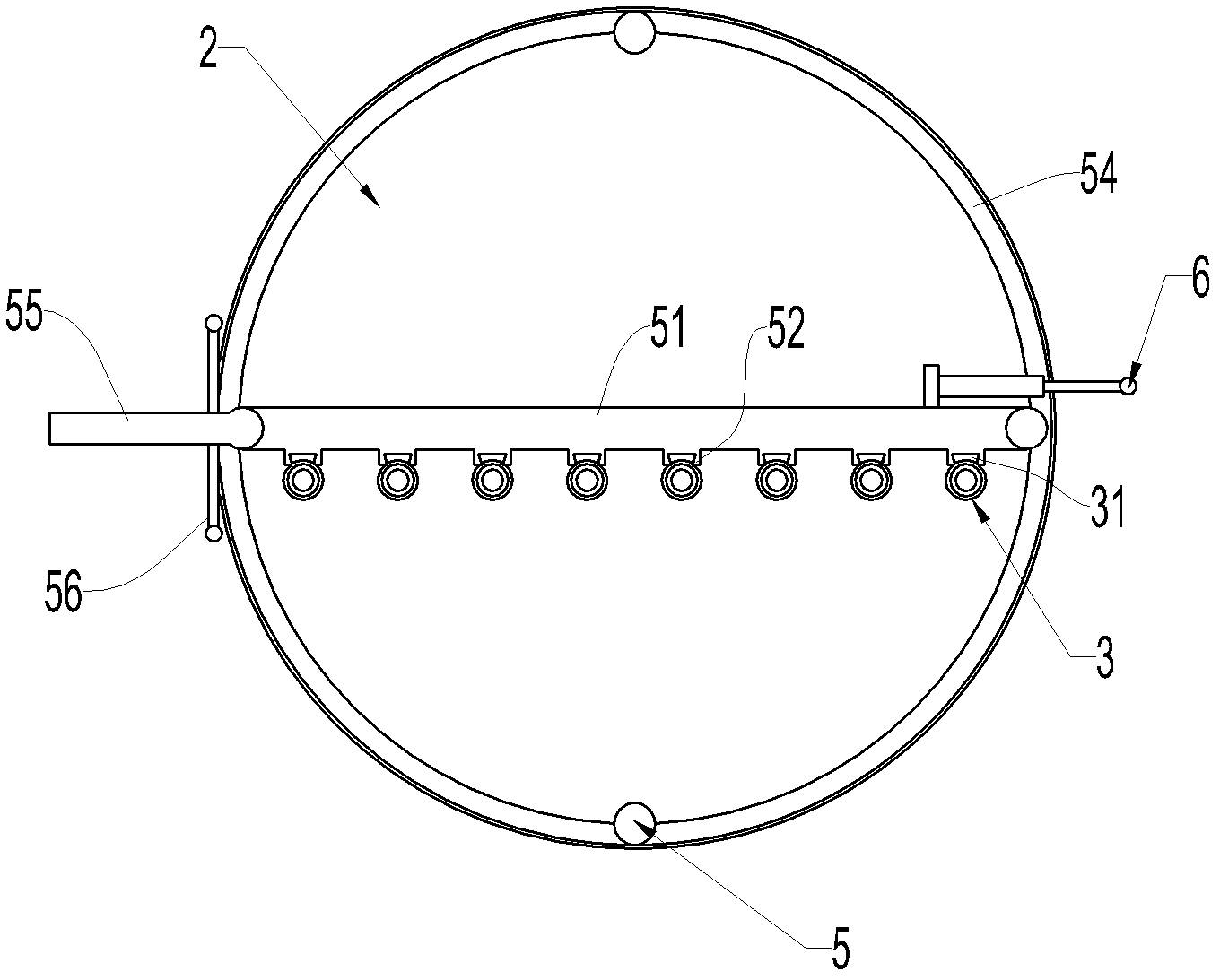

[0029] refer to figure 1 , figure 2 and image 3 , a mine roadheader, including a tower 1 that can be lifted and jointed, a rotating platform 2, and a plurality of typhoon drills 3 installed on the rotating platform; the jacking and jointing tower 1 described here is an existing mature technology and is widely used For tower cranes, there are at least two structures applicable to this utility, which are respectively a tower with a rotary structure and a fixed tower. The tower with a rotary structure can also include two types of upper rotary structure and tower body rotary structure. The latter can be The rotation of the tower 1 itself is used to drive the rotary platform 2 to rotate; if the ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com