Vortex compressor capable of being assembled through clamping lower cover component

A scroll compressor and cover assembly technology, which is applied to rotary piston machinery, pump components, mechanical equipment, etc., can solve the problems of large overall compressor volume, high installation accuracy, and high processing costs, and save processing costs and materials. Cost, easy processing, and the effect of improving installation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 2

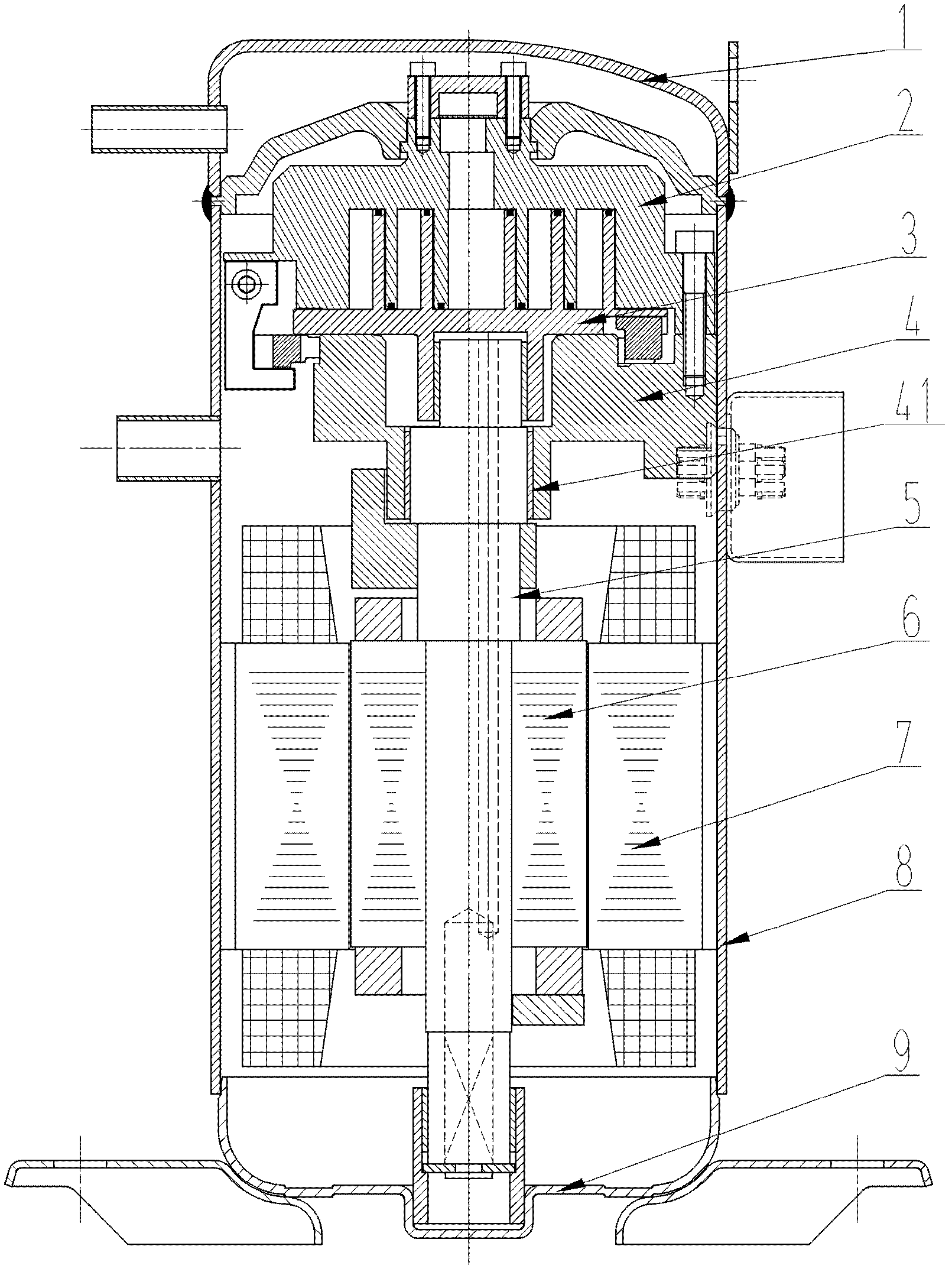

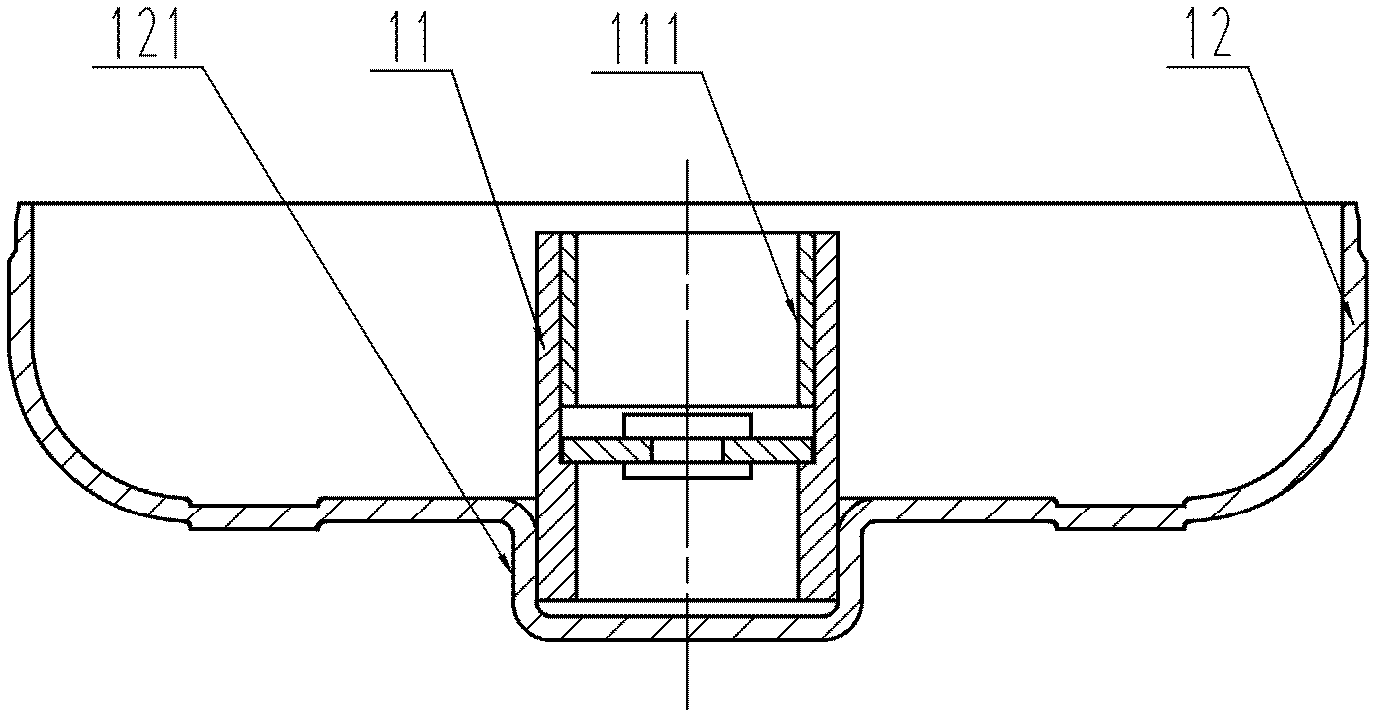

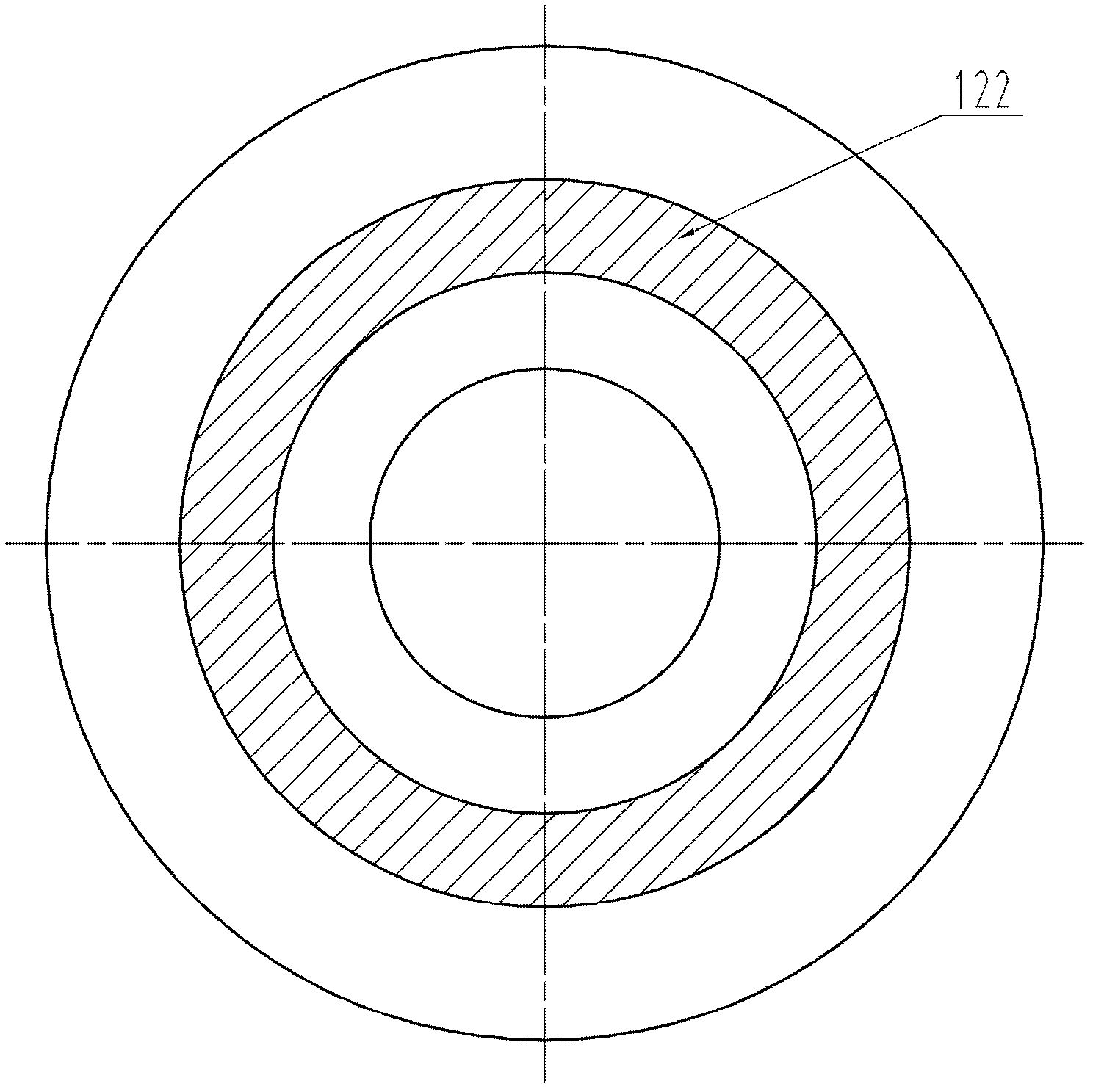

[0034] The specific embodiment of the present invention is shown in the accompanying drawings. The scroll compressor that can be assembled by clamping the lower cover assembly is composed of an upper cover 1, a fixed scroll 2, a movable scroll 3, an upper support 4, a main shaft 5, The motor rotor 6, the motor stator 7 and the housing 8 are composed; the motor stator 7 is interference-fitted into the housing 8; the upper support 4 is interference-fitted into the housing 8 above the motor stator 7; Equipped with movable scroll 3, fixed scroll 2 and upper cover 1; the upper end of the main shaft 5 equipped with motor rotor 6 is inserted into the upper support 4; it is characterized in that the lower end of the housing 8 is equipped with a lower The cover assembly II10, the lower cover assembly II10 is composed of the lower support II13 and the lower cover II14; the middle part of the lower cover II14 is processed with a through hole 141, and the lower support II13 passes through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com