Method and device for synchronizing crystallizer vibration hydraulic cylinders

A crystallizer vibration and hydraulic cylinder technology, applied in fluid pressure actuating devices, servo motors, mechanical equipment, etc., can solve the problems of slow dynamic response and poor synchronization accuracy, and achieve the goal of overcoming poor synchronization accuracy, safe operation, and synchronization accuracy. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

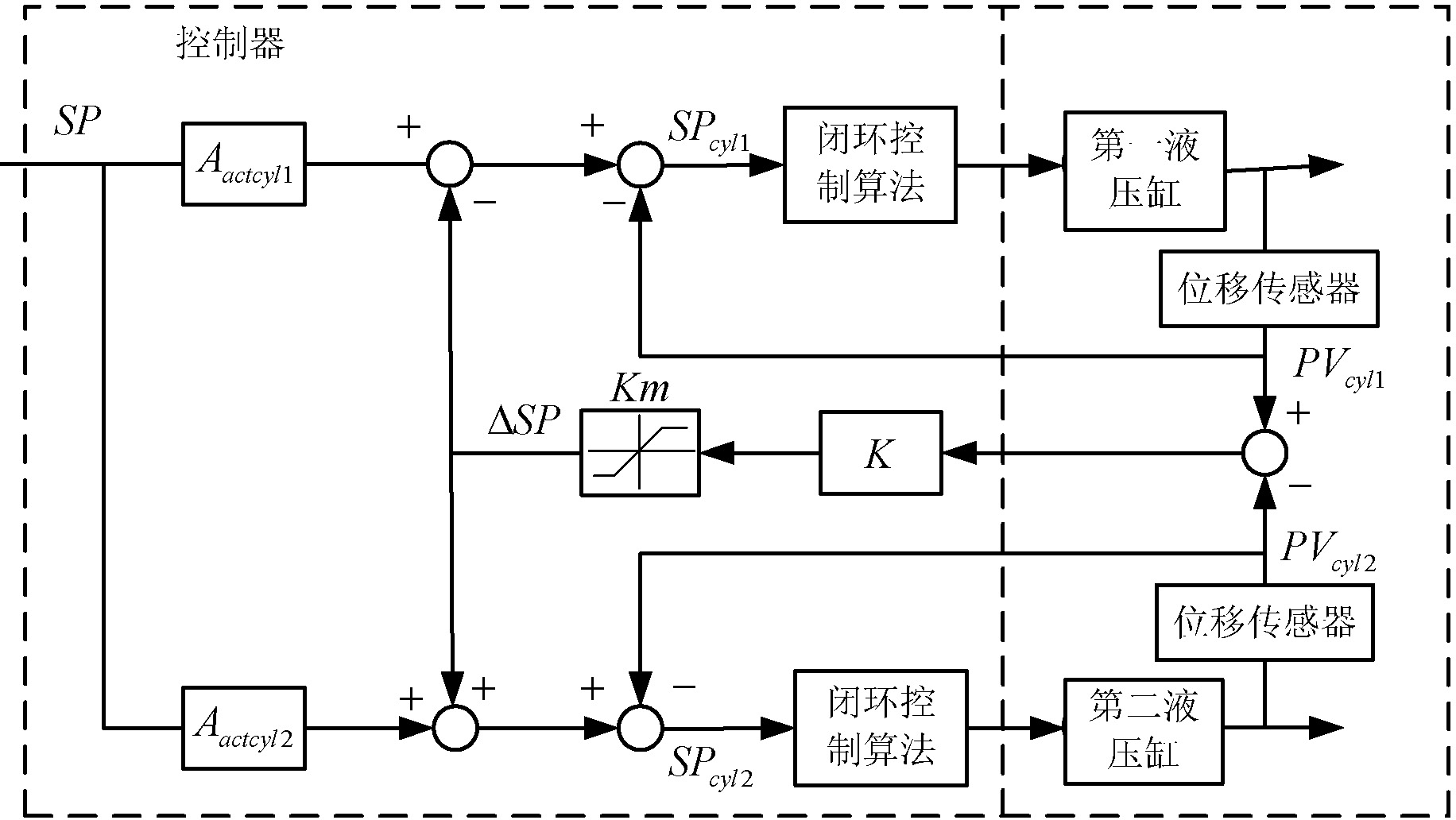

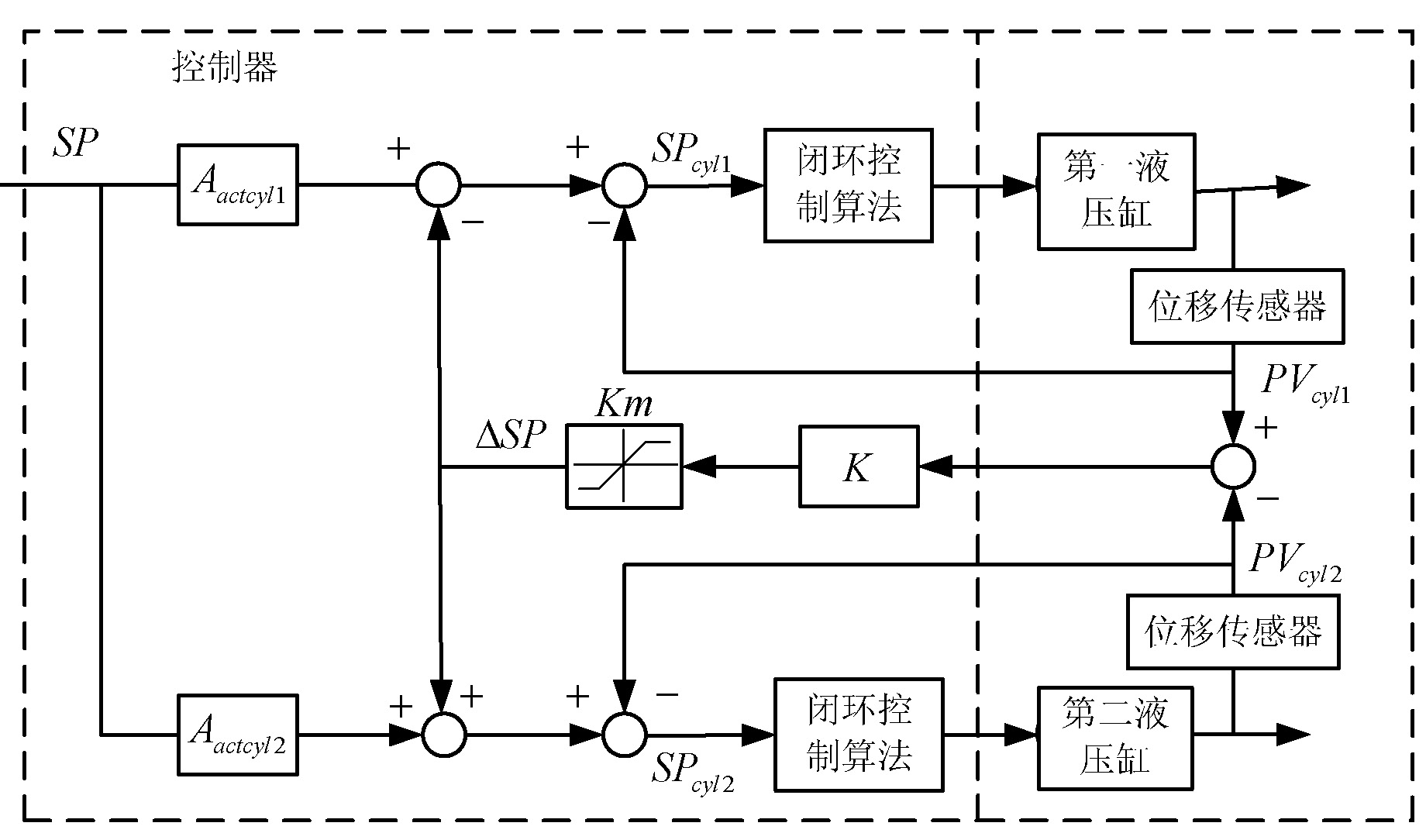

[0015] The technical scheme that the present invention solves its technical problem adopts is:

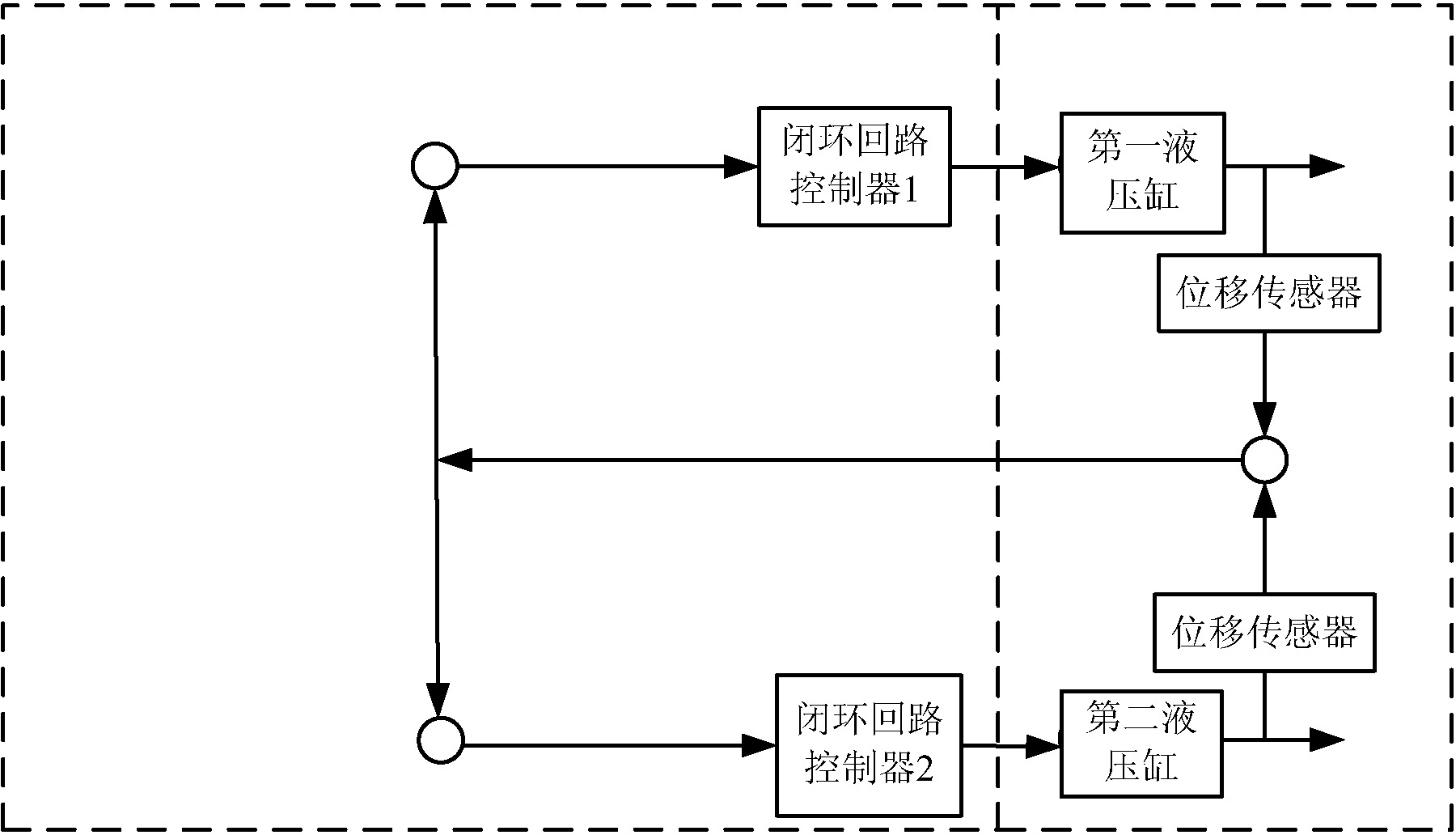

[0016] The present invention is different from the traditional master-slave control method, that is, the master-slave method that only sends control signals to the master cylinder, and the slave cylinder takes the position of the master cylinder as the action target. The synchronous movement of the two hydraulic cylinders is realized by continuously adjusting the position setting value of each hydraulic cylinder at the same time regardless of the master and slave. The main steps are:

[0017] 1. Calculate the amplitude setting value of the hydraulic cylinder according to the reference amplitude and the actual amplitude of the two hydraulic cylinders;

[0018] 2. Calculate the position setting value of the hydraulic cylinder according to the amplitude setting value calculated in step 1 and the actual positions of the two hydraulic cylinders;

[0019] 3. Measure the actual position ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com