Transmission hydraulic control system having flow augmentation

A technology of hydraulic control system and transmission, applied in the direction of components with teeth, transmission control, belt/chain/gear, etc., which can solve the problem that the main pump cannot provide hydraulic fluid pressure level and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The following description is merely exemplary in nature and is not intended to limit the invention, its application or uses.

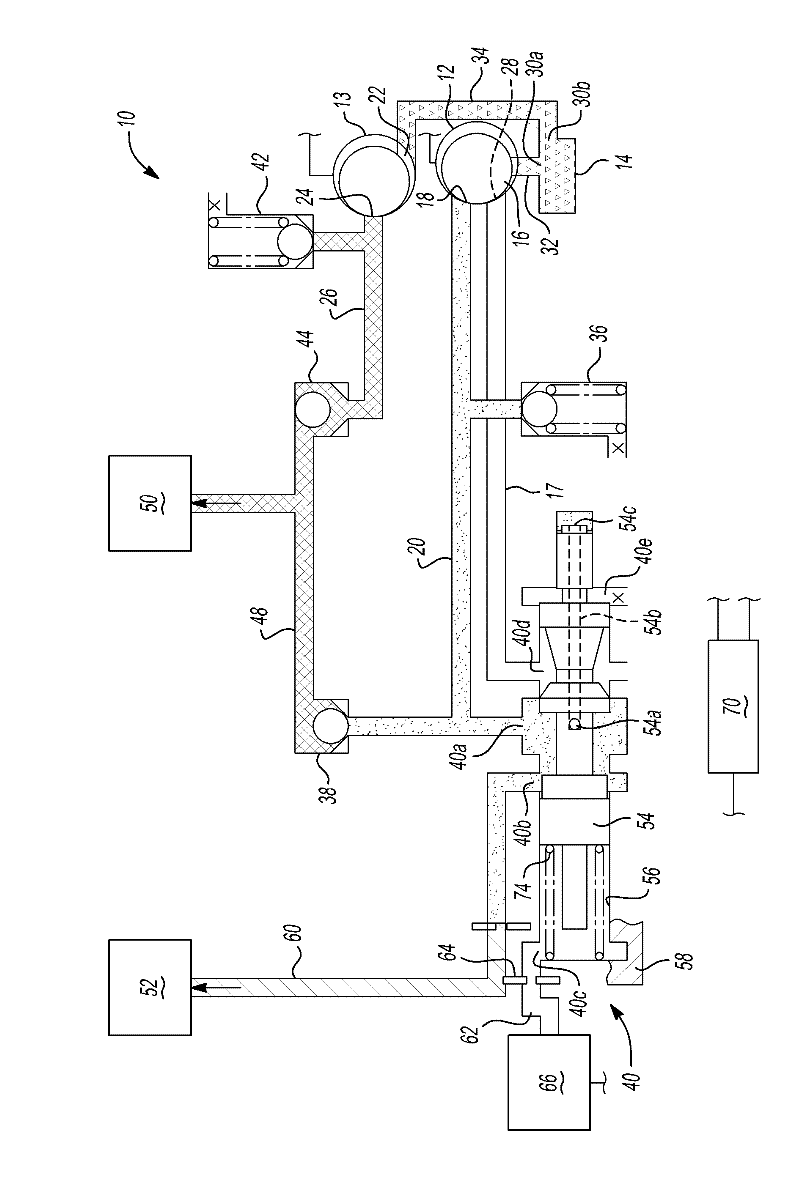

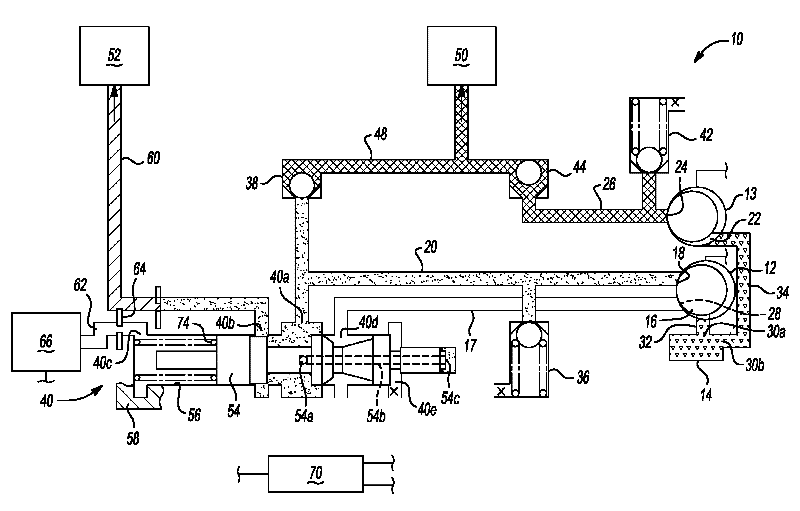

[0058] refer to figure 1 , a subsystem of a hydraulic control system for a transmission of a motor vehicle is indicated generally with reference numeral 10 . Subsystem 10 operates as a source of pressurized hydraulic fluid for the hydraulic control system and includes a main pump 12 and an auxiliary pump 13 both in fluid communication with a sump 14 . The pump 12 can be driven directly by the internal combustion engine in the motor vehicle, or by an electric motor or other prime mover. Pump 12 includes an inlet port 16 and an outlet port 18 . Inlet port 16 communicates with sump 14 and fluid return line 17 and outlet port 18 communicates with a low pressure branch or supply line 20 . Pump 12 may be of various types, such as a gear pump, vane pump, rotary pump, or any other positive displacement pump.

[0059] The auxiliary pump 13 is driven ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com