Compound sealing device

A sealing device and composite sealing technology, which is applied to the sealing of the engine, engine components, mechanical equipment, etc., can solve the problems of medium leakage, high processing precision, and adding rigid material support rings, etc., to achieve low medium leakage and small medium leakage , good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

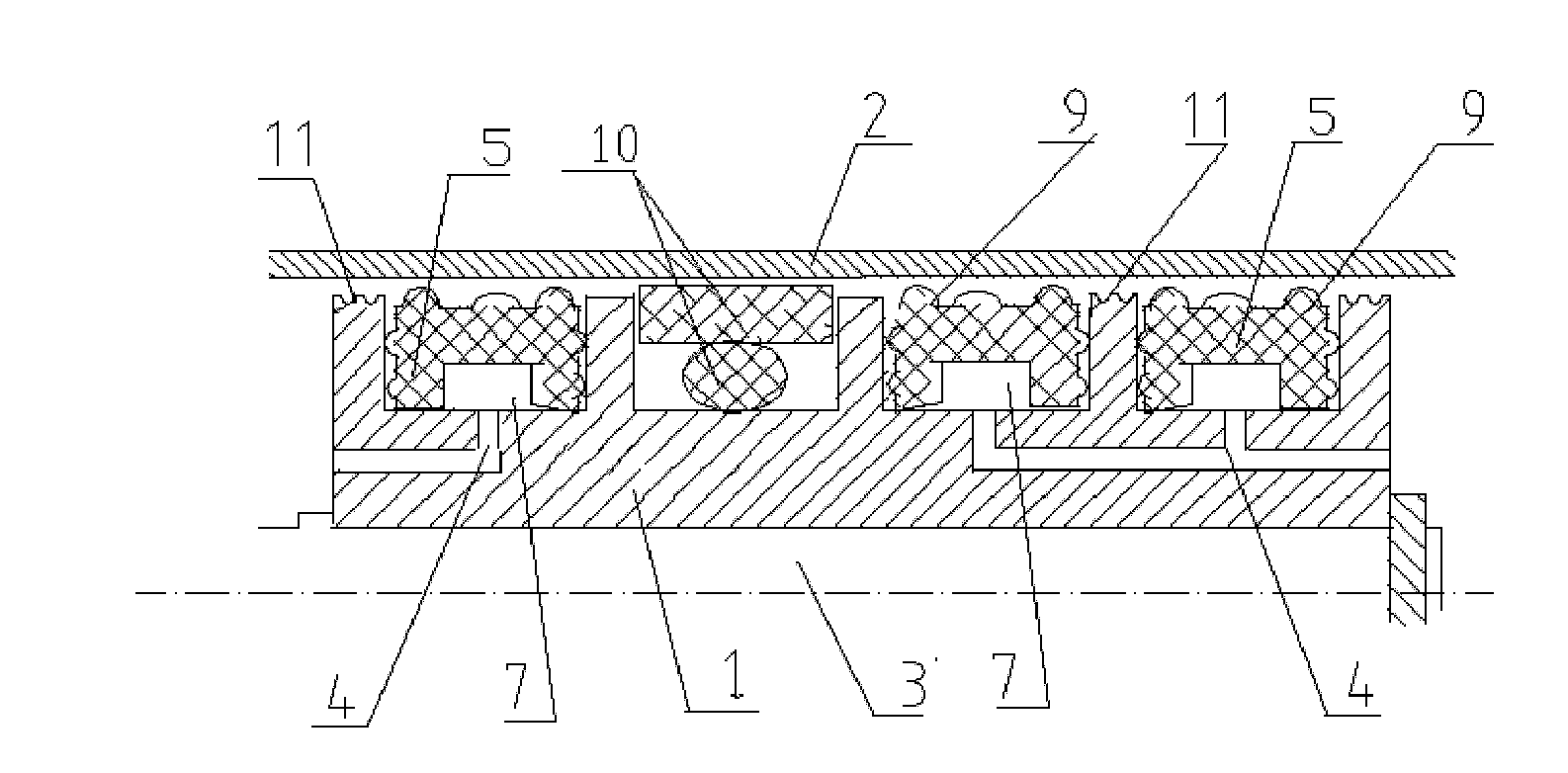

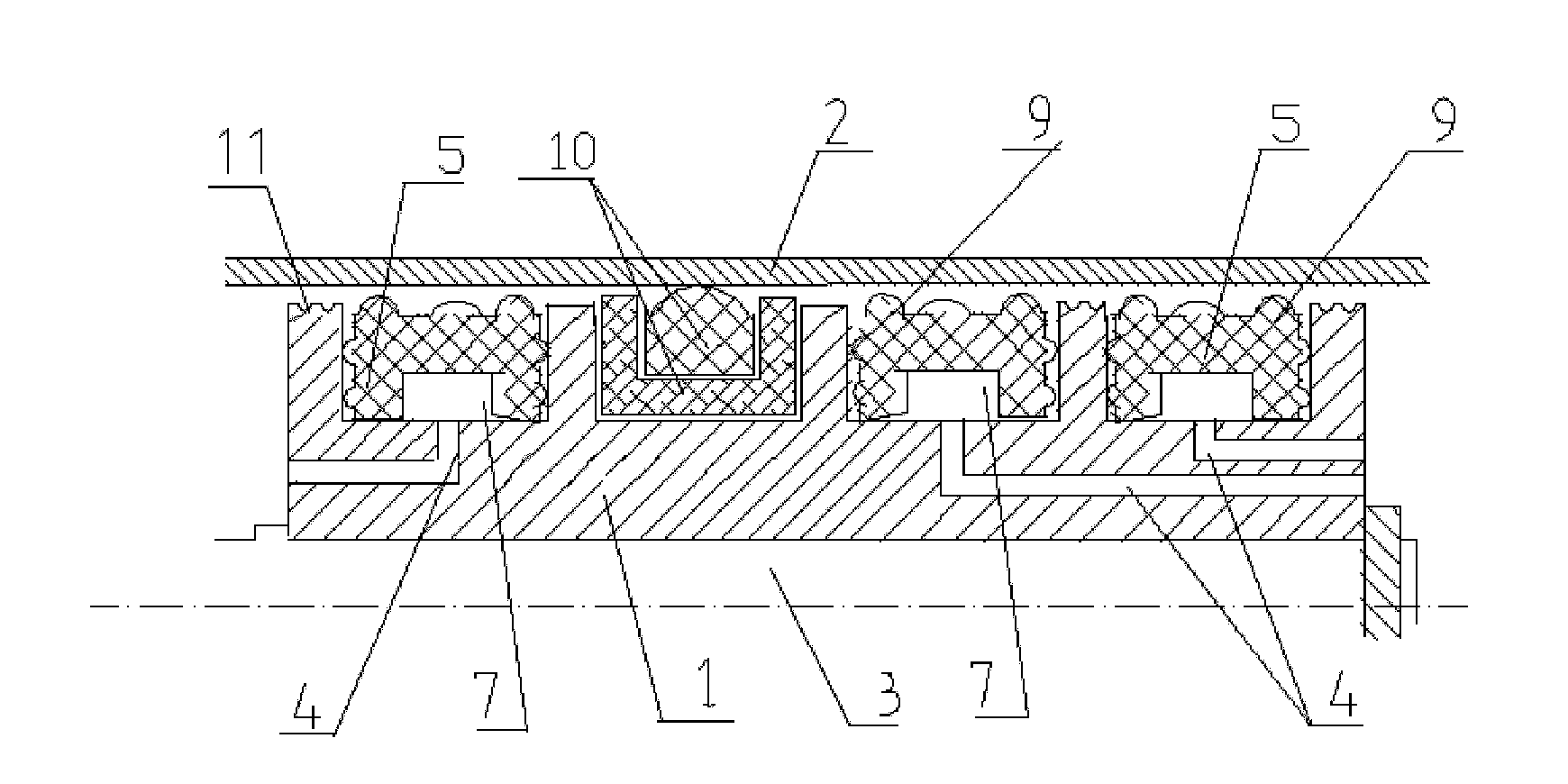

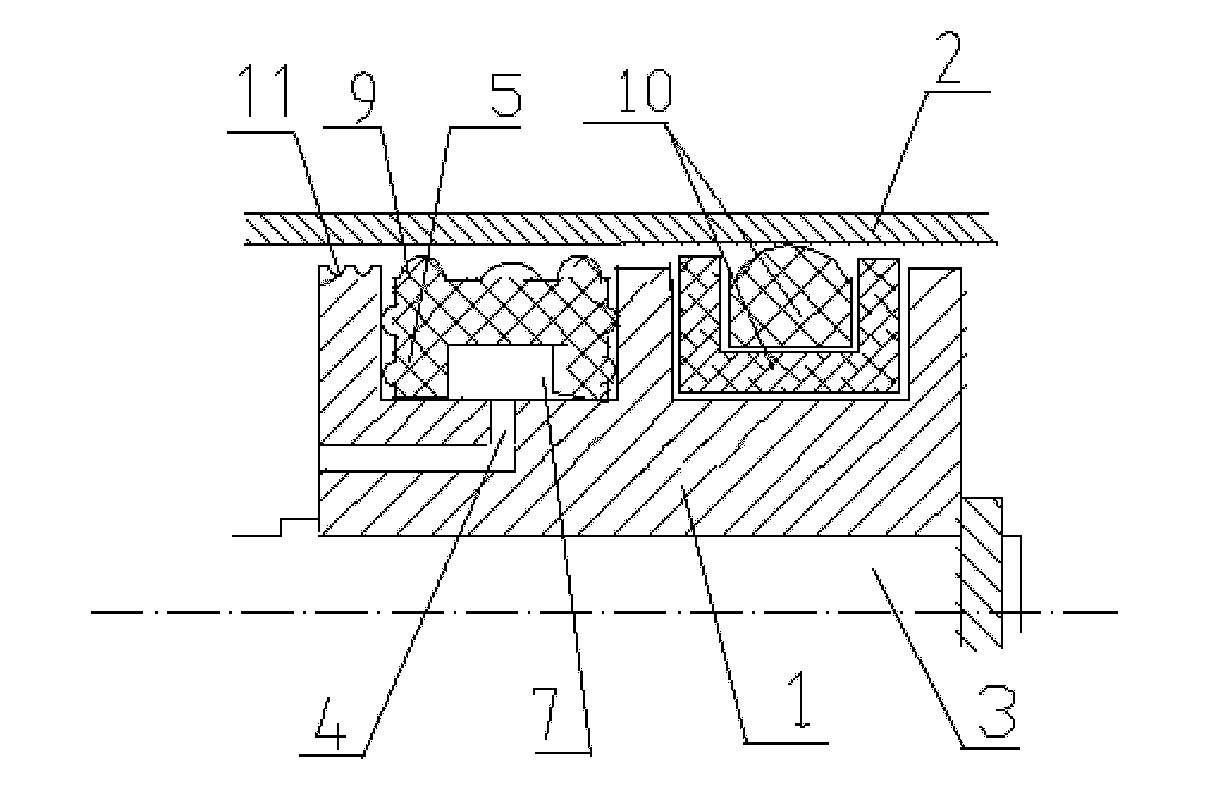

[0022] From figure 1 , figure 2 , image 3 and Figure 4 It can be seen from the figure that when the sealing device of the present invention is used as a shaft sealing device, a certain amount of space is added to the end of the existing O-ring, Yx-ring or combined sealing element 10 on the sealing device block 1 close to the direction of action of the working medium. The n-shaped sealing ring is placed in the groove, and the n-shaped sealing ring 5 for the shaft is installed in each groove; the end surface of the sealing device block 1 near the end of the working medium action direction is provided with a passage hole 4 for guiding the medium into the inner cavity 7 of each sealing ring, The medium can be introduced into the inner chamber 7 of the n-ring seal 5 for the shaft. Since the n-shaped sealing ring 5 is at the end of the composite sealing device close to the action direction of the working medium, the n-shaped sealing ring 5 first plays a sealing role. After th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com