Boiler comprising water cooling system for variable-section hearth

A water-cooling system and technology in the furnace, which is applied in the boiler field, can solve the problem that the variable-section furnace cannot adopt the spiral tube water cooling system, and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

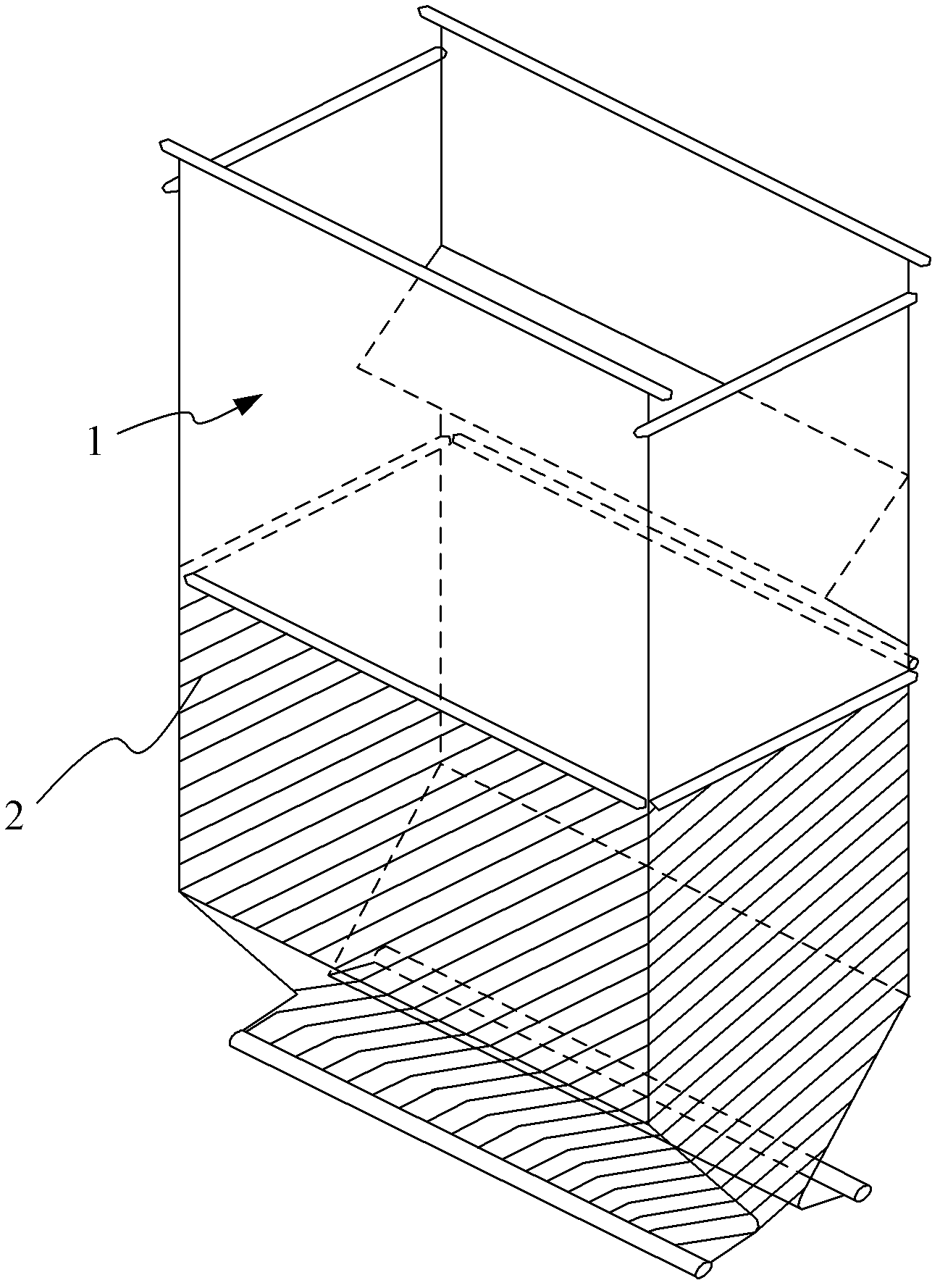

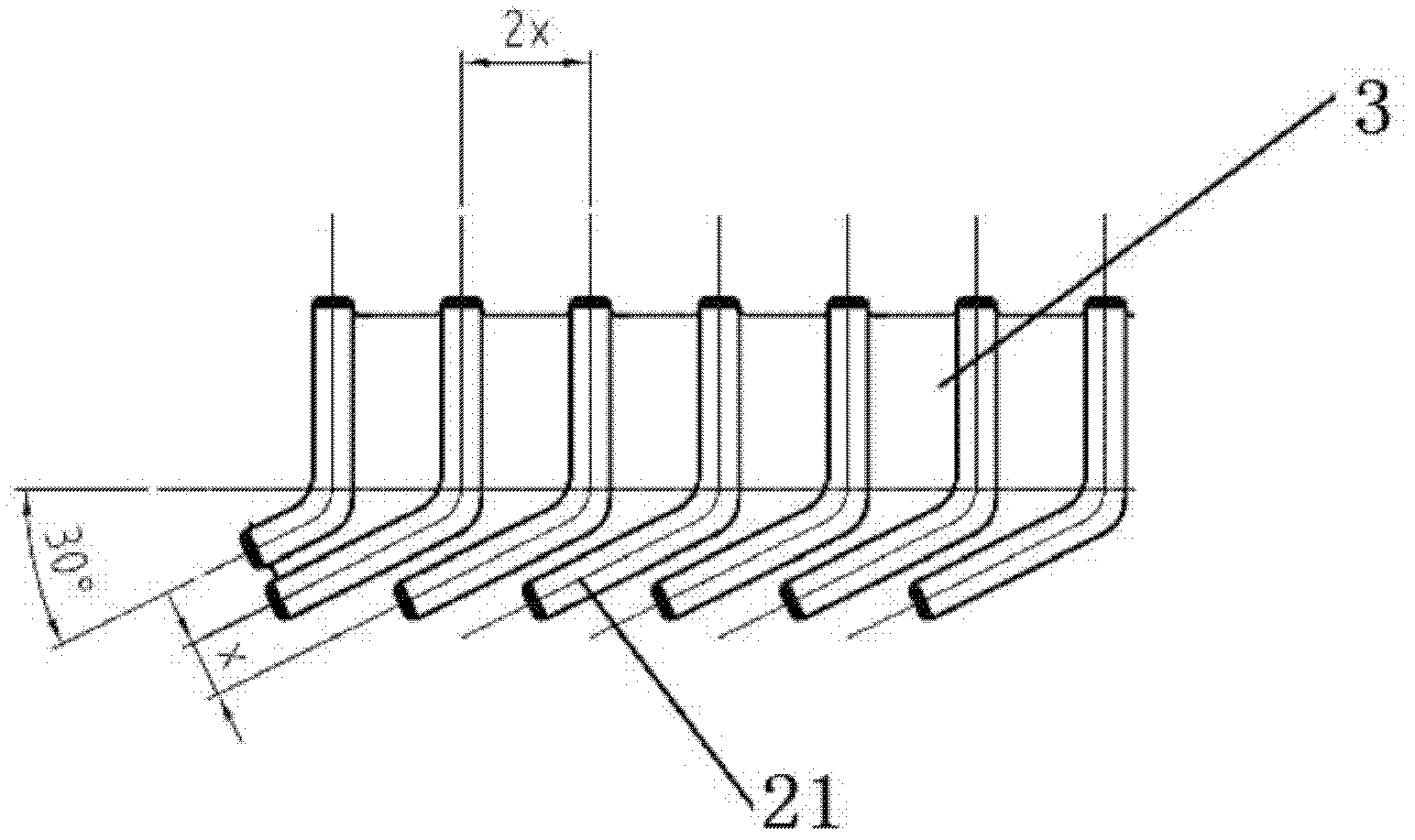

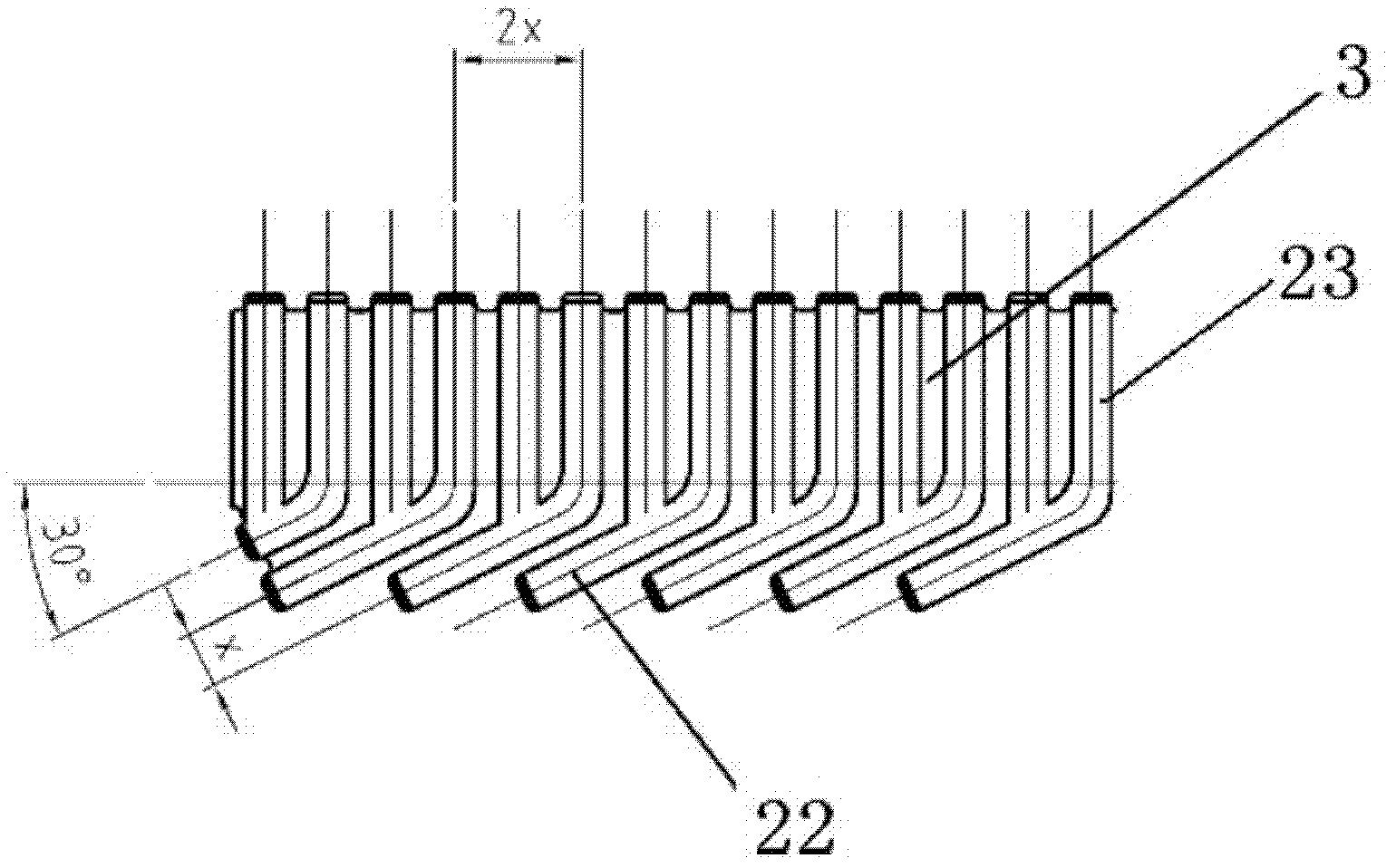

[0021] Such as Figure 4 and 5 As shown, the boiler comprising the water-cooling system used in the variable-section furnace of this embodiment includes a lower front wall 101, a lower rear wall 102, and a side wall 103. The lower front wall 101, the lower rear wall 102 and the side wall 103 The lower hearth 100 is enclosed. The lower front wall 101 extends upwards to form an upper front wall 201 , the lower rear wall 102 extends upwards to form an upper rear wall 202 , and the upper furnace 200 is surrounded by the upper front wall 201 , the upper rear wall 202 and the side walls 103 . The lower furnace 100 is divided into a transition zone 111 , a lower furnace 112 and an ash hopper 113 from top to bottom. The lower front wall 101, the lower rear wall 102, the side wall 103, the upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com