Measuring instrument testing fixture for length measuring machine

A technology for measuring instruments and testing fixtures, which is applied in the field of geometric quantity measurement, and can solve problems affecting the use of instruments by units, occupancy and storage, and long cycles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

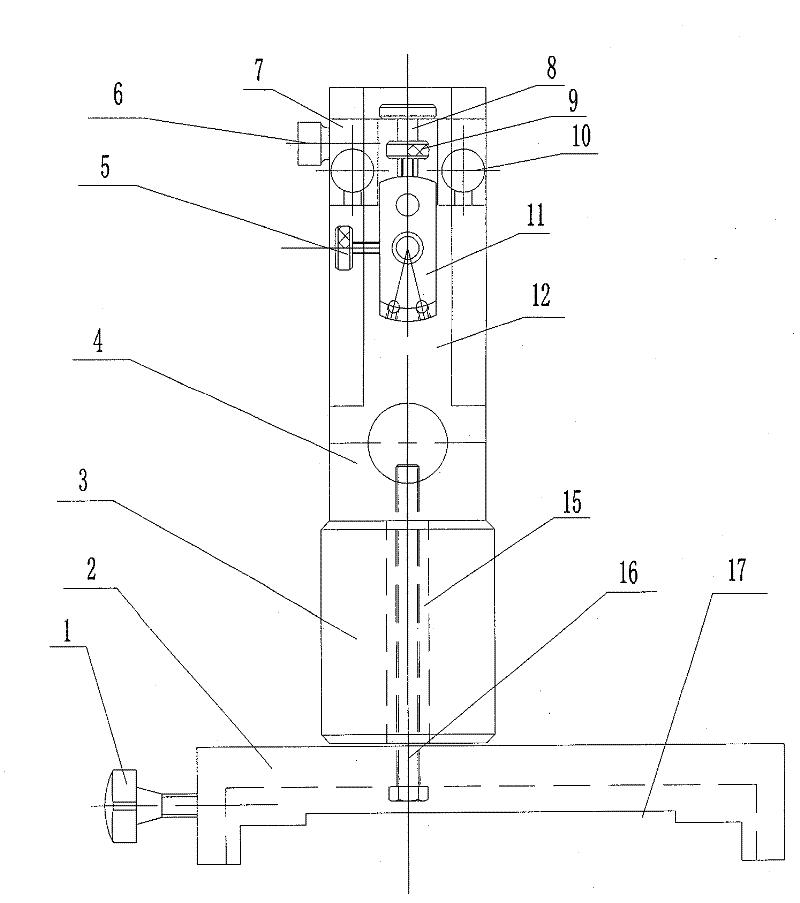

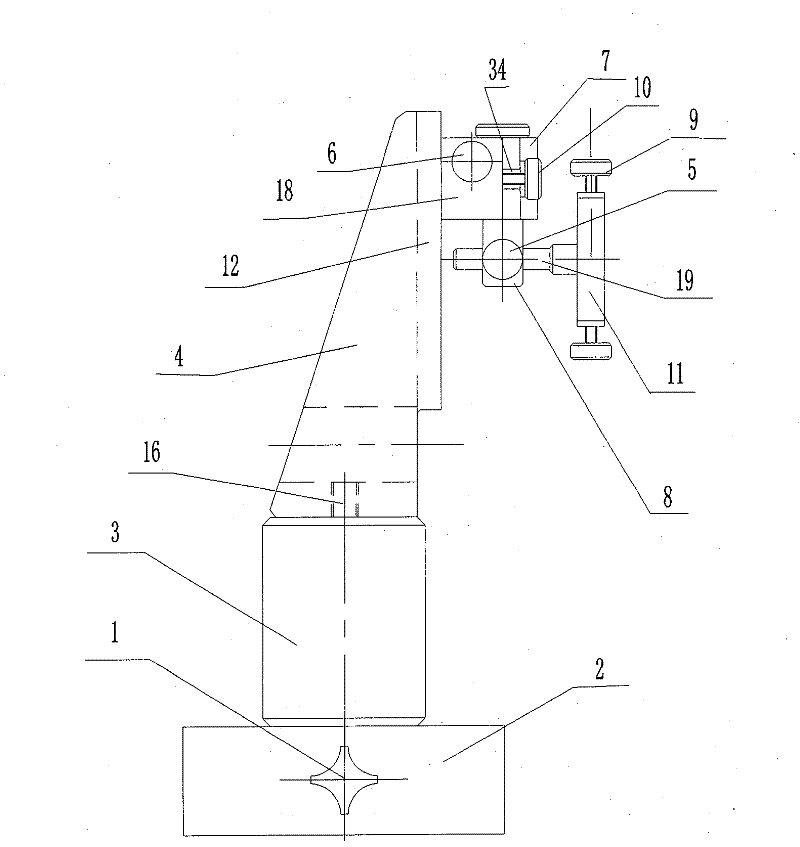

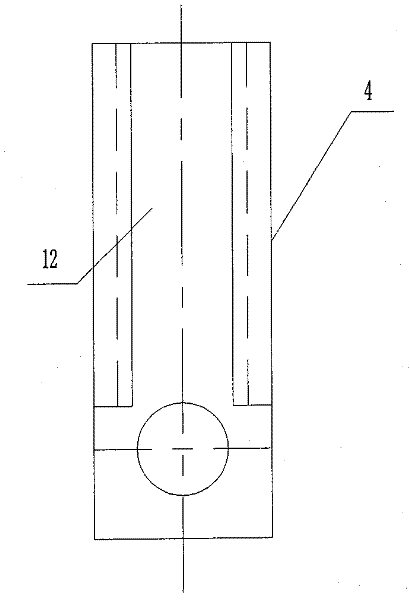

[0025] Example 1, such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 and Figure 15The illustrated embodiment 1 includes a base 2 whose bottom surface 17 matches the track of the length measuring machine, a spacer 3 , a bracket 4 , a clamping assembly, a measuring head fixing frame assembly and a measuring head fixing seat 40 . Have screw hole I on the side wall of base 2, it is clamped and fixed on the track side wall of length-measuring machine by locking bolt A1. There are concentric screw holes on the base 2, spacer 3, bracket 4 and probe fixing seat 40 respectively, and the base 2, spacer 3 and bracket 4 are fixed by long screws 16 or the base 2, spacer 3 and the probe are fixed Seat 40 is fastened and fixed by long screw 42, and 15 is the concentric screw hole that has on pad 3, and 20 is the concentric screw hole that has on support...

Embodiment 2

[0026] Embodiment 2, other structures of this embodiment are completely the same as Embodiment 1, except that there is no probe fixing frame assembly in this embodiment.

[0027] 1. The following is an example of measuring the inner diameter dial indicator (the division value is 1 μm, and the indication error is required to be no more than 7 μm) to introduce the working principle of the device in detail.

[0028] 1. Installation: first install a flat measuring cap on the measuring rod of the optical meter tube of the length measuring machine, align the tail pipe of the length measuring machine with any integer value, and then install the base, pad, bracket and clamping assembly of the present invention On the guide rail of the length measuring machine. Compress the inner diameter gauge by 1 / 4 turn and install it in the clamping hole, loosen the locking bolt A, roughly adjust the workbench left and right, make the movable measuring head of the inner diameter gauge roughly in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com