Method for indirectly measuring liquid level and volume of liquid in storage tank and gravitational method based level instrument

The technology of a level meter and a storage tank is applied in the field of level meter, which can solve the problems of inconvenience and inaccuracy, and achieve the effects of convenient use, convenient installation and promotion and implementation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

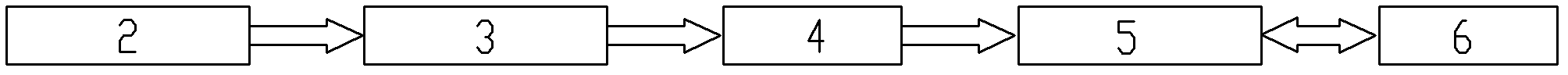

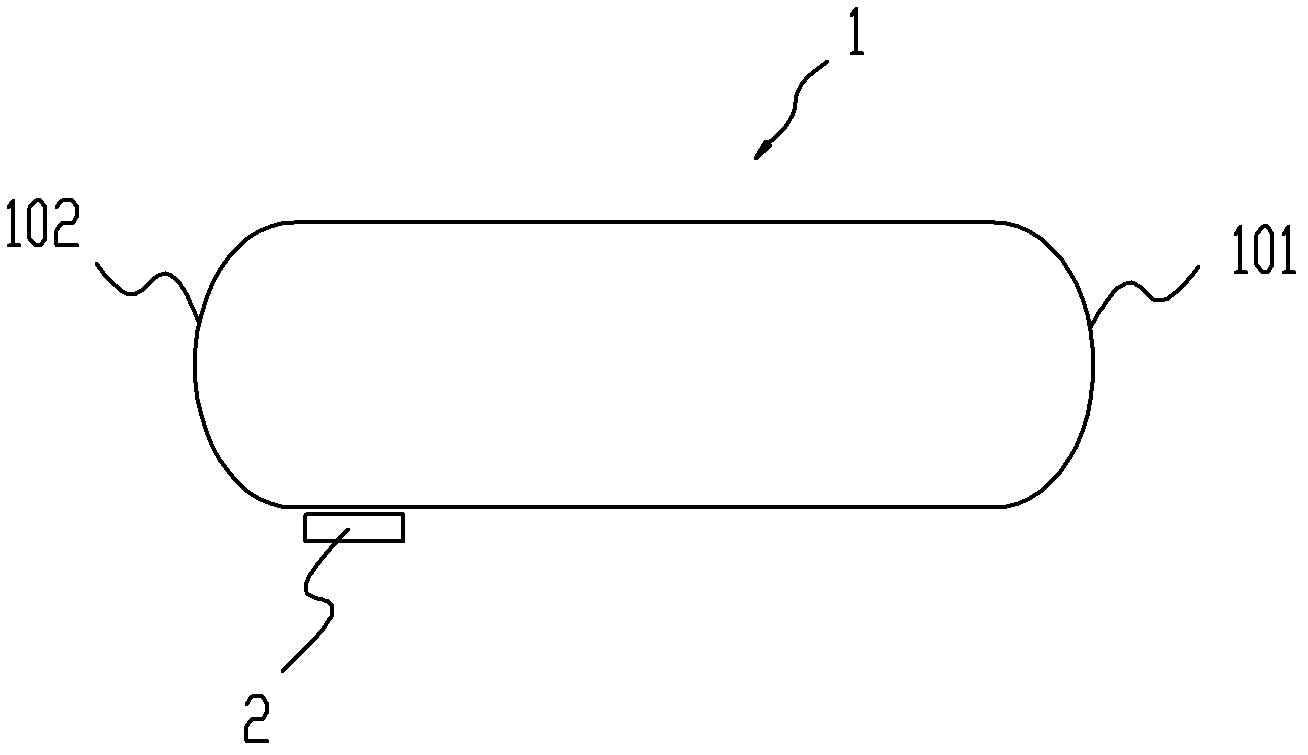

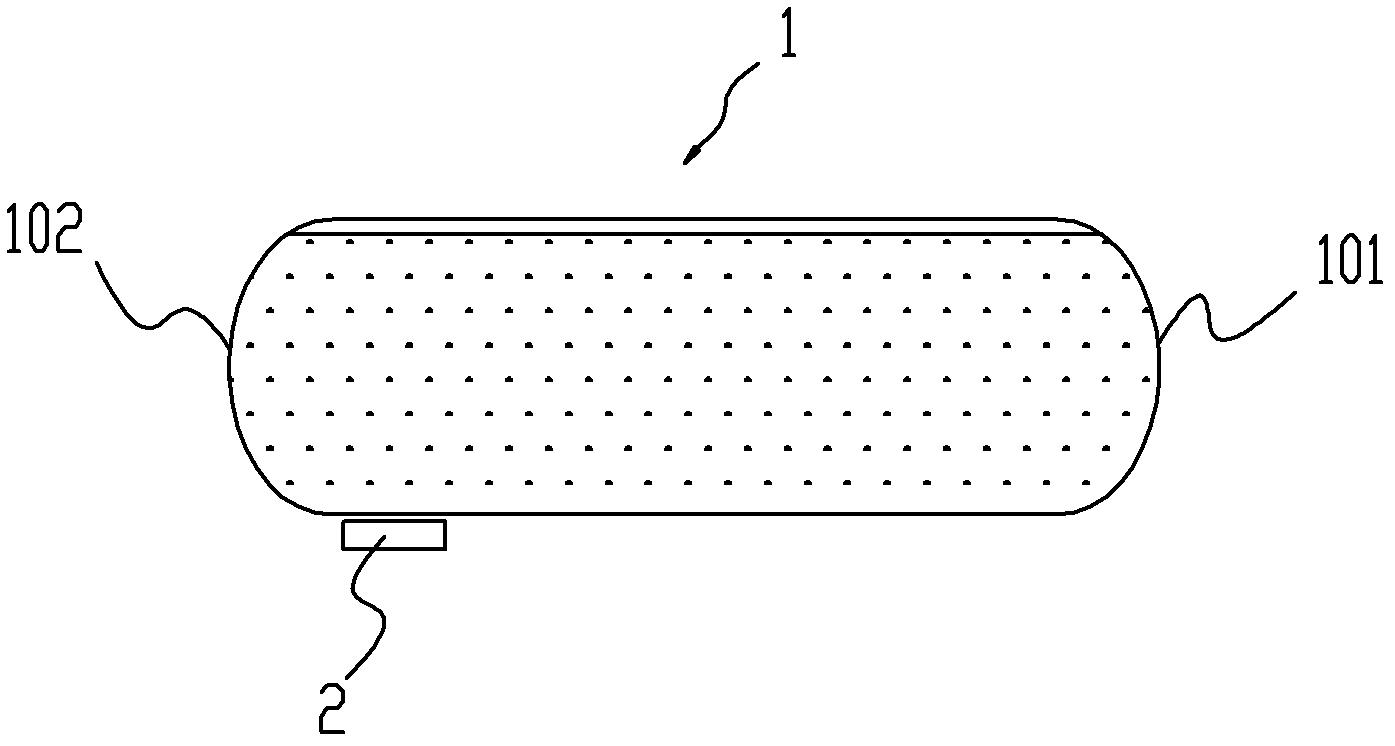

[0027] Combine figure 1 , figure 2 versus image 3 , A gravity level meter, including a storage tank 1, a gravity sensor 2, a signal amplifier 3, an A / D conversion module 4, a microprocessor 5 and a display module 6. One side of the above-mentioned storage tank 101 is fixedly connected to the fixed base of the storage tank, and a fulcrum is formed at the bottom of the one side of the tank end, and the other side of the storage tank 102 is also fixedly connected to the fixed base of the storage tank. A measuring point is arranged at the bottom of the other side of the tank end. The measuring point is in contact with a gravity sensor located below it. The gravity sensor is installed on the fixed base of the tank; the gravity sensor is connected to the signal amplifier, and the signal amplifier is connected to the A / D conversion module. The A / D conversion module is connected to the microprocessor, and the microprocessor is connected to the display module.

[0028] Combining the abo...

Embodiment 2

[0035] Combine Figure 4 , Figure 5 versus Image 6 , A gravity level meter, including a storage tank 1, a gravity sensor 2, a signal amplifier 3, an A / D conversion module 4, a microprocessor 5 and a display module 6. One side of the tank end 101 of the above-mentioned storage tank is fixedly connected to the storage tank fixing base 7, and a fulcrum is formed at the bottom of the one side of the tank end, and the other side tank end 102 of the storage tank is also fixedly connected to the storage tank fixing base 7. And a measuring point is arranged at the bottom of the tank end on the other side, and the measuring point is in contact with the gravity sensor located below it. The gravity sensor is installed on the fixed base of the tank; the gravity sensor is connected to the signal amplifier, and the signal amplifier is connected to the A / D conversion module. The A / D conversion module is connected to the microprocessor, and the microprocessor is connected to the display modu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com