Development experimental platform for detecting and controlling automobile tire pressure ABS (Anti Lock Brake System)/ASR (Acceleration Slip Regulation) key part

A technology of control development and test bench, applied in the testing of machines/structural components, testing of vehicles, measuring devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

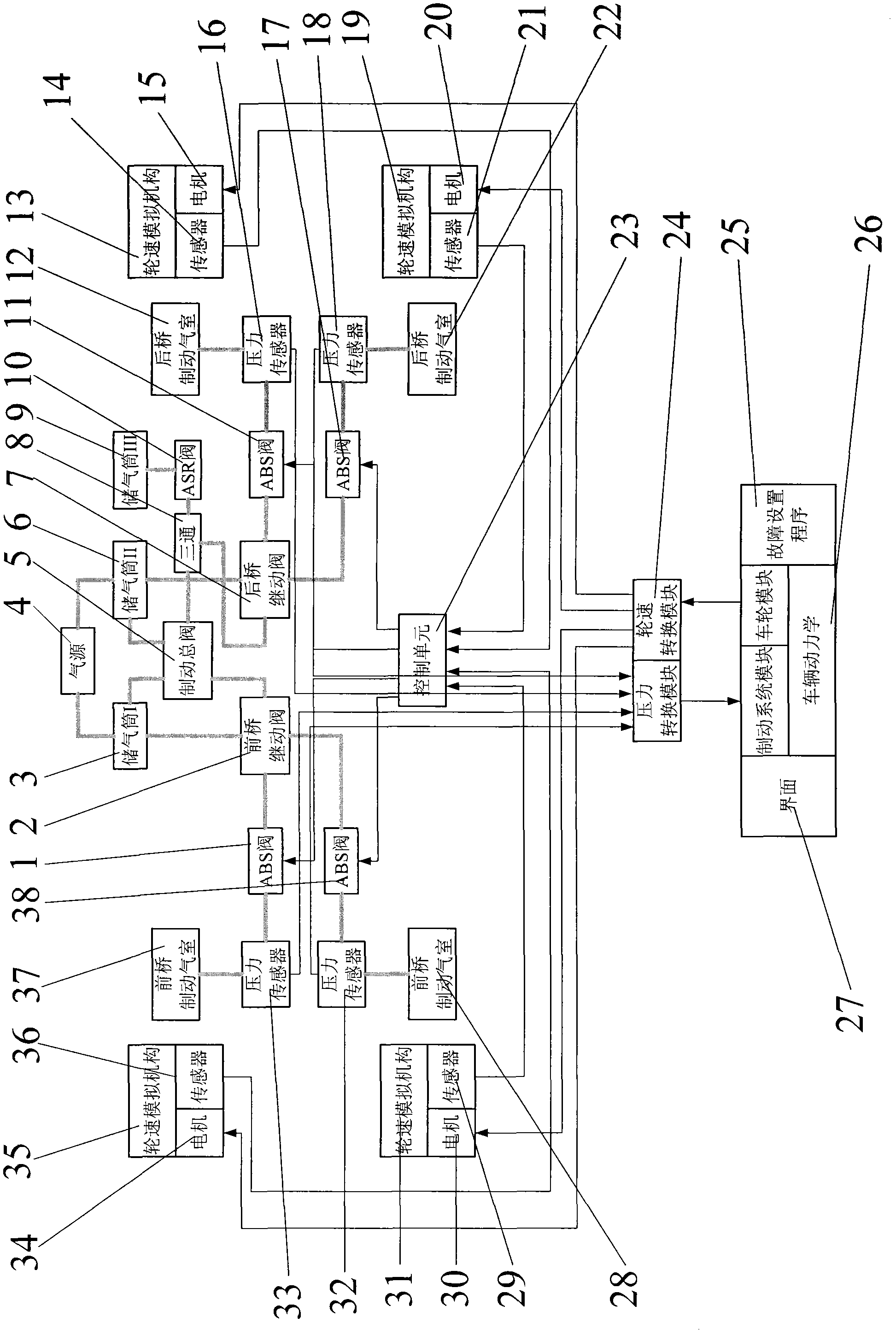

[0028] refer to figure 1 , an automobile air pressure ABS / ASR key component detection and control development test bench, composed of mechanical system, brake wheel cylinder simulation system, human-computer interaction system (with fault setting module 25, vehicle dynamics 26, interface 27), signal control system, signal acquisition system 24 and wheel speed simulation circuit system. Among them, each wheel is equipped with a wheel speed simulation circuit system, figure 1 Among them are 13, 19, 31, 35 respectively.

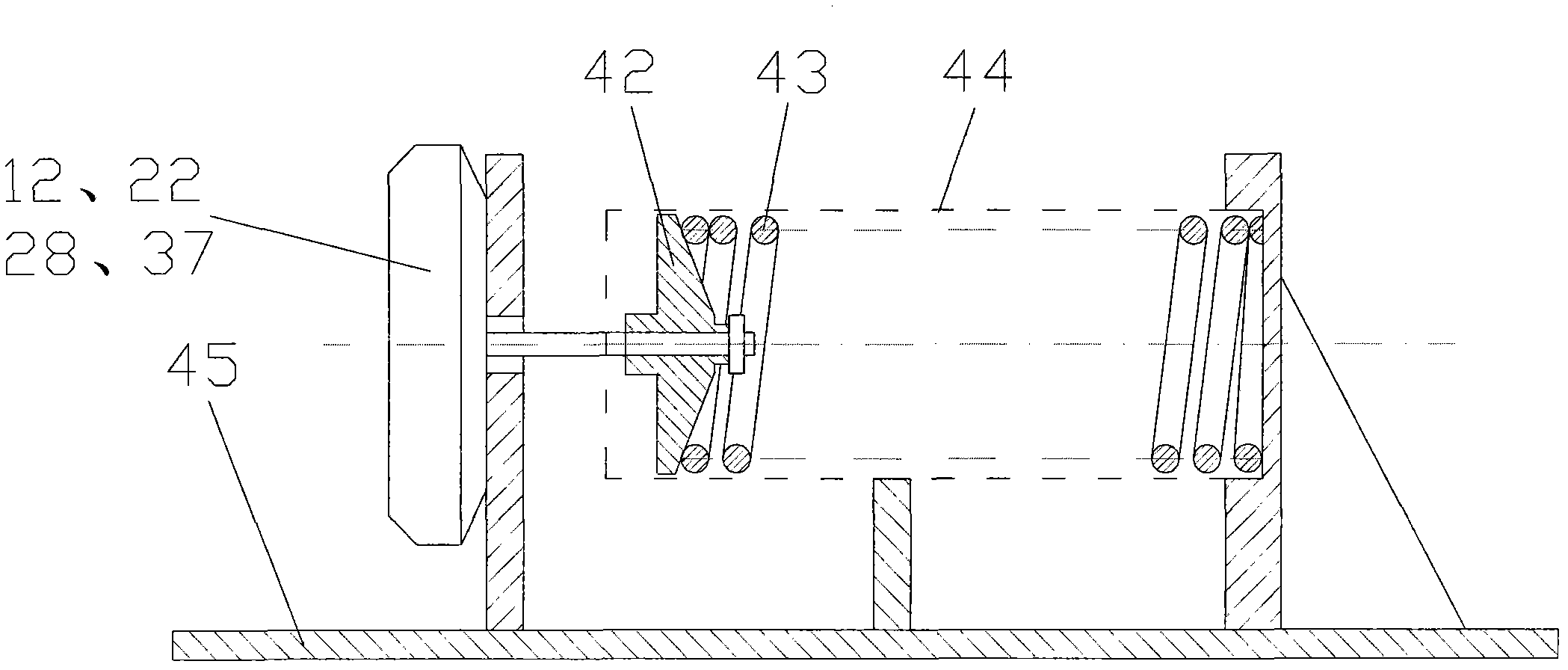

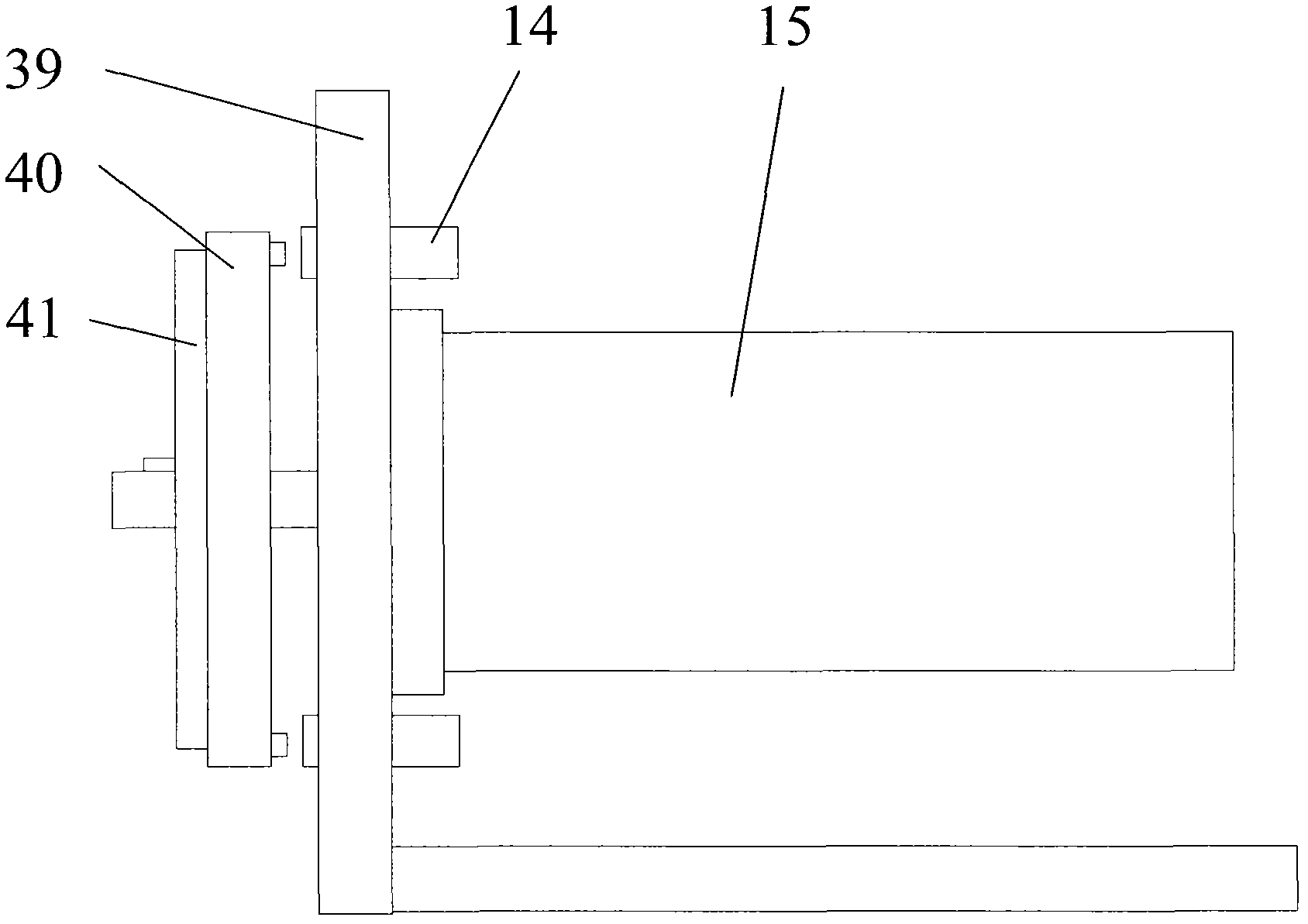

[0029] Described mechanical system comprises base frame, front and rear axle brake air chamber (wherein rear axle brake air chamber 12,22, front axle brake air chamber 28,37), valve body fixing mechanism, air source 4, air reservoir, Operating console, pedal bracket, master brake valve 5; the brake wheel cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com