Measuring device and measuring method of concrete viscosity

A technology of measuring devices and measuring methods, applied in measuring devices, flow characteristics, instruments, etc., can solve the problems of high cost, complicated instrument structure, inaccurate measurement of shear torque, etc., and achieve the effect of simple structure and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

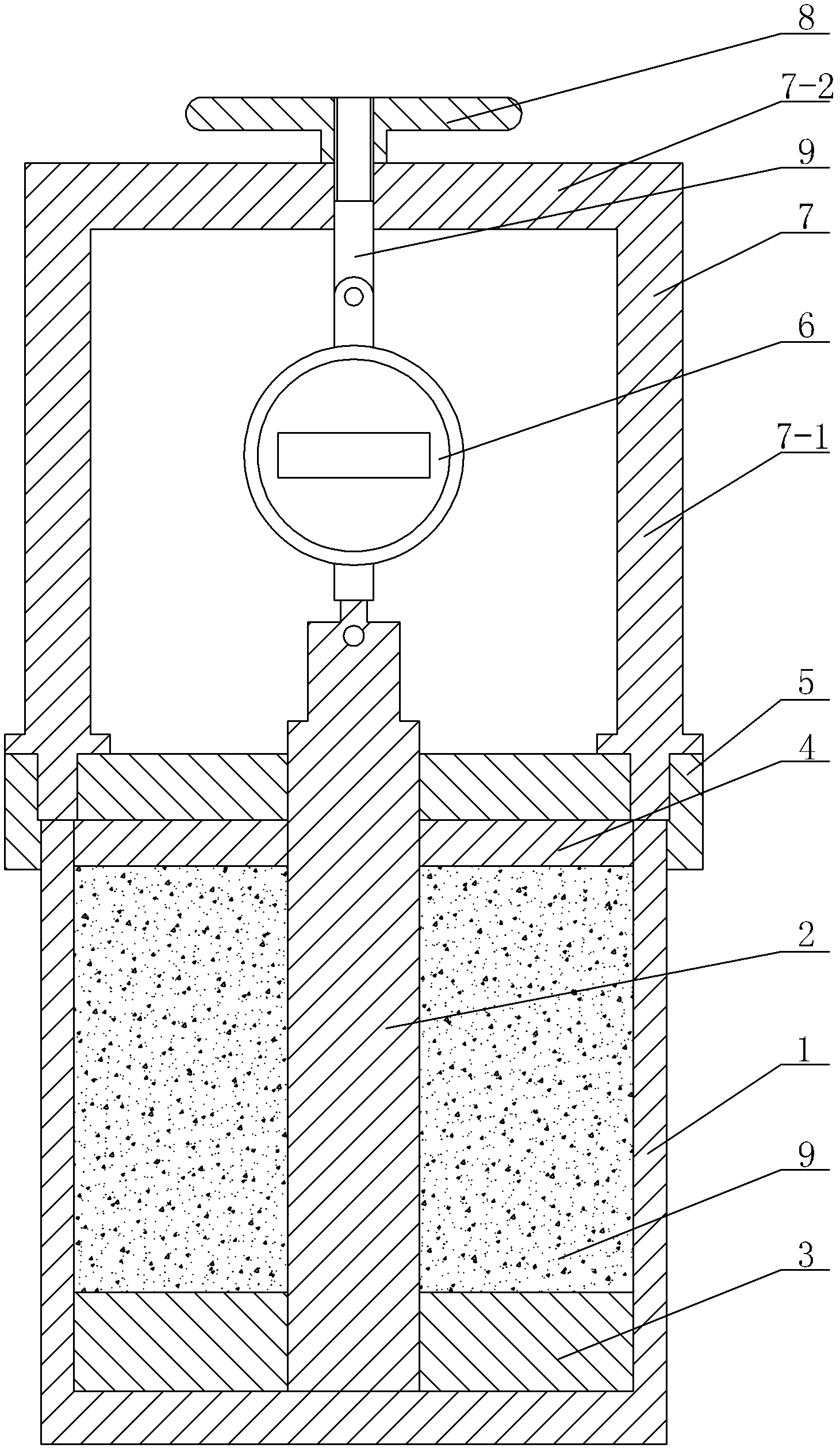

[0012] Specific implementation mode one: combine figure 1 Describe this embodiment mode, a kind of concrete viscosity measuring device described in this embodiment mode comprises container 1, steel cylinder 2, tray 3, pressure plate 4, container cover 5 and electronic scale 6, and tray 3 is arranged on the inner cavity of container 1 On the bottom surface, the pressure plate 3 is arranged at the container mouth of the container 1, the lower end of the steel cylinder 2 passes through the center hole of the tray 3, and the lower end surface of the steel cylinder 2 is in contact with the bottom surface of the inner cavity of the container 1, and the steel cylinder 2 The upper end passes through the central hole of the pressure plate 4 and the central hole of the container cover 5 successively from bottom to top, and the upper end of the steel cylinder 2 is connected with the lower end of the electronic scale 6 by pins, and the outer wall of the steel cylinder 2 is provided with th...

specific Embodiment approach 2

[0013] Specific implementation mode two: combination figure 1 To illustrate this embodiment, a concrete viscosity measuring device described in this embodiment also includes a bracket 7, a hand wheel 8 and a screw 9, and the bracket 7 is a door composed of two columns 7-1 and a beam 7-2 Glyph support 7, the lower end of each column 7-1 is respectively inserted in the corresponding hole on the edge of container cover 5, the lower end of screw rod 9 is connected with the upper end of electronic scale 6 by pin, and the upper end of screw rod 9 passes crossbeam 7- The through hole in 2 middle parts is connected with handwheel 8. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0014] Specific implementation mode three: combination figure 1 To illustrate this embodiment, the tray 3 and the pressure plate 4 of a concrete viscosity measuring device described in this embodiment are both made of engineering plastics. Other compositions and connections are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com