Electrically controlled detecting device for microwave medium coating and detecting method thereof

A microwave medium and detection device technology, applied in the direction of measuring devices, measuring electrical variables, measuring resistance/reactance/impedance, etc., to achieve the effect of improving test accuracy and easy handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Embodiments of the present invention will be described in detail below.

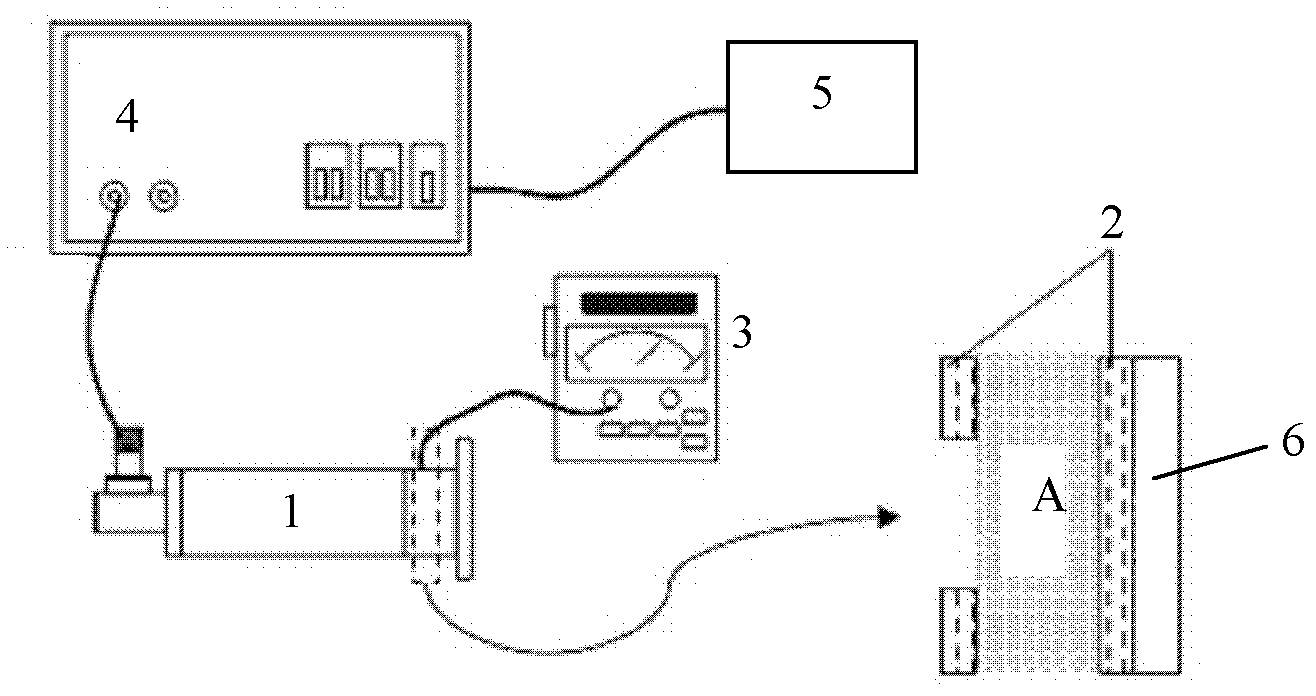

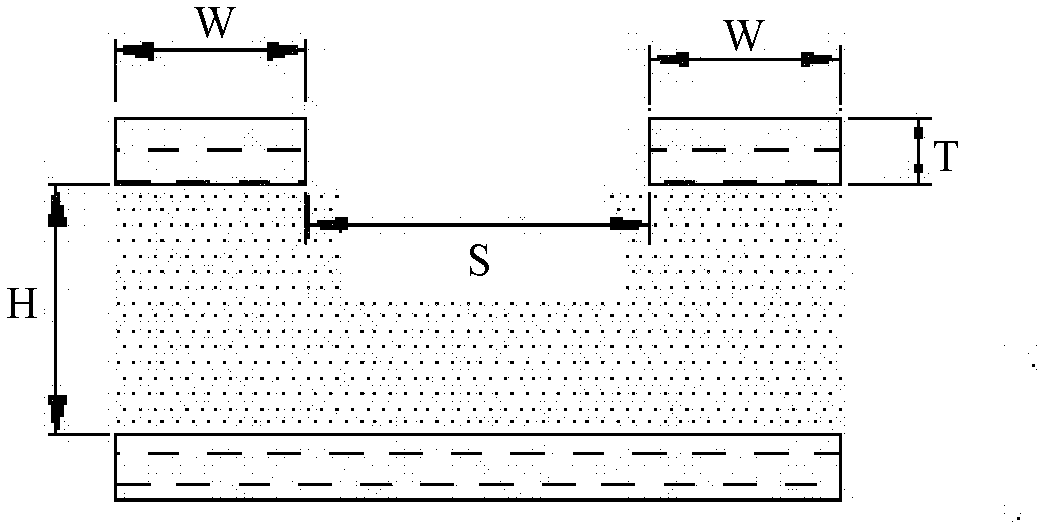

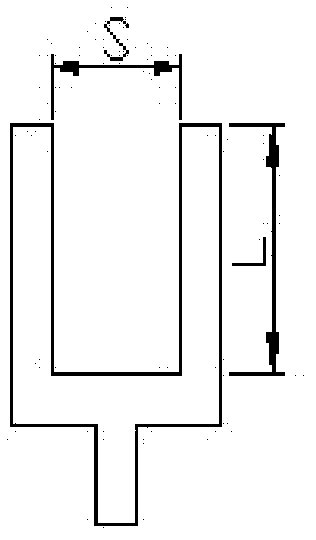

[0025] figure 1A block diagram of the structural composition of the embodiment of the microwave dielectric coating electric control detection device according to the present invention is given. The embodiment of the electric control detection device of the microwave dielectric coating is provided with a rectangular waveguide 1, a parallel coupled microstrip electrode 2, a DC stabilized power supply 3, a vector network analyzer 4, a computer 5 and a short circuit board 6; the rectangular waveguide 1 The front end of the VNA is connected to the port of the vector network analyzer 4, the parallel coupling microstrip electrode 2 is arranged in the middle of the rectangular waveguide 1, the rear end of the rectangular waveguide 1 is connected to the short circuit board 6, and the output terminal of the DC stabilized power supply 3 is connected to the parallel coupling microstrip The electrodes 2 are c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com