Blanking control circuit for LED (light-emitting diode) display screens and LED drive chip

A technology of LED display and blanking control, which is applied to static indicators, instruments, etc., can solve the problems of low display quality of LED display and inability to control LED constant current, so as to improve image display quality and eliminate smear phenomenon Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

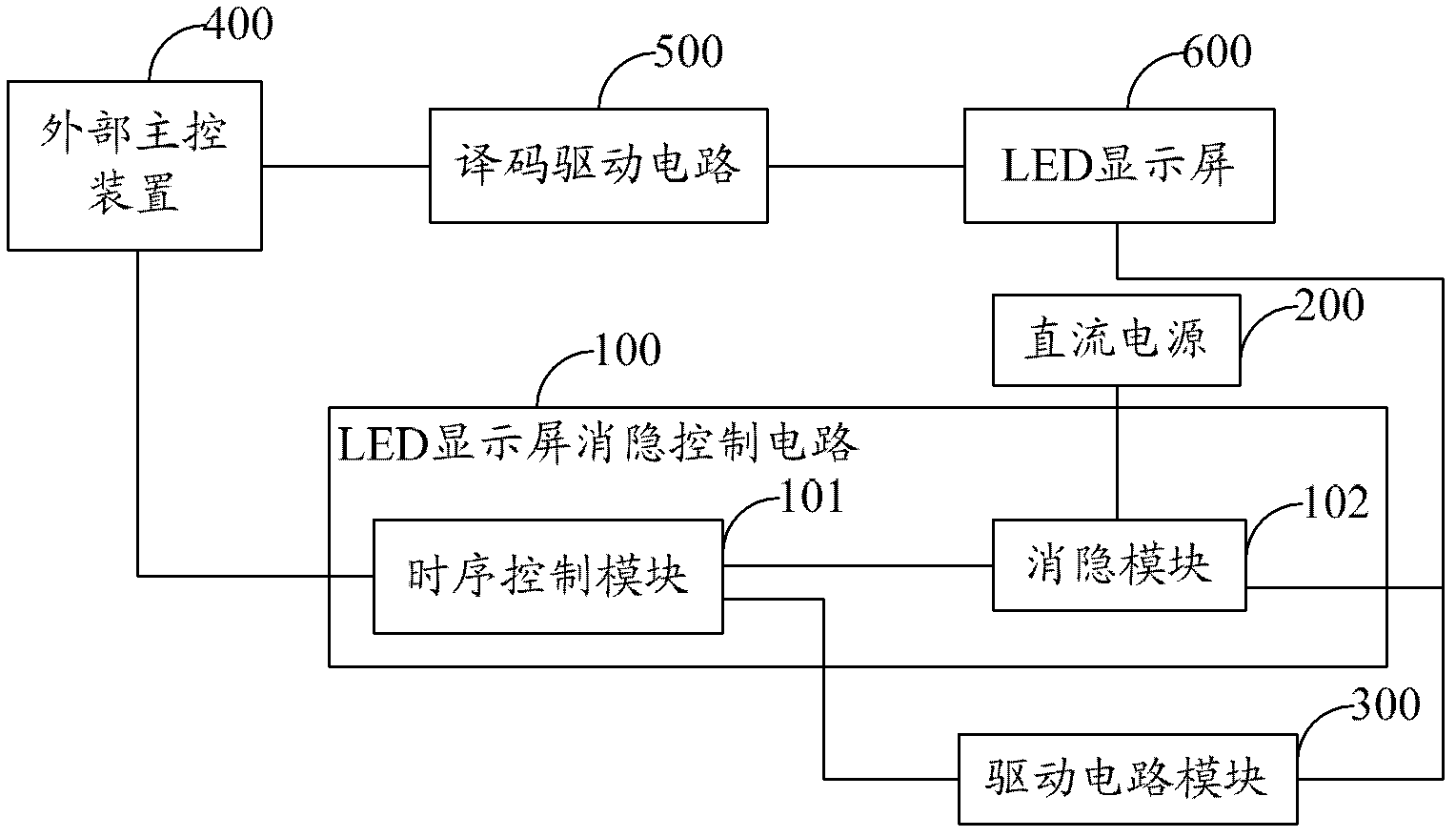

[0021] figure 1 It shows the module structure diagram of the LED display screen blanking control circuit provided by the first embodiment of the present invention. For the convenience of explanation, only the parts related to the first embodiment of the present invention are shown, and the details are as follows:

[0022] The LED display screen blanking control circuit 100 is connected with the DC power supply 200, the drive circuit module 300 and the external main control device 400, and the LED display screen blanking control circuit 100 includes:

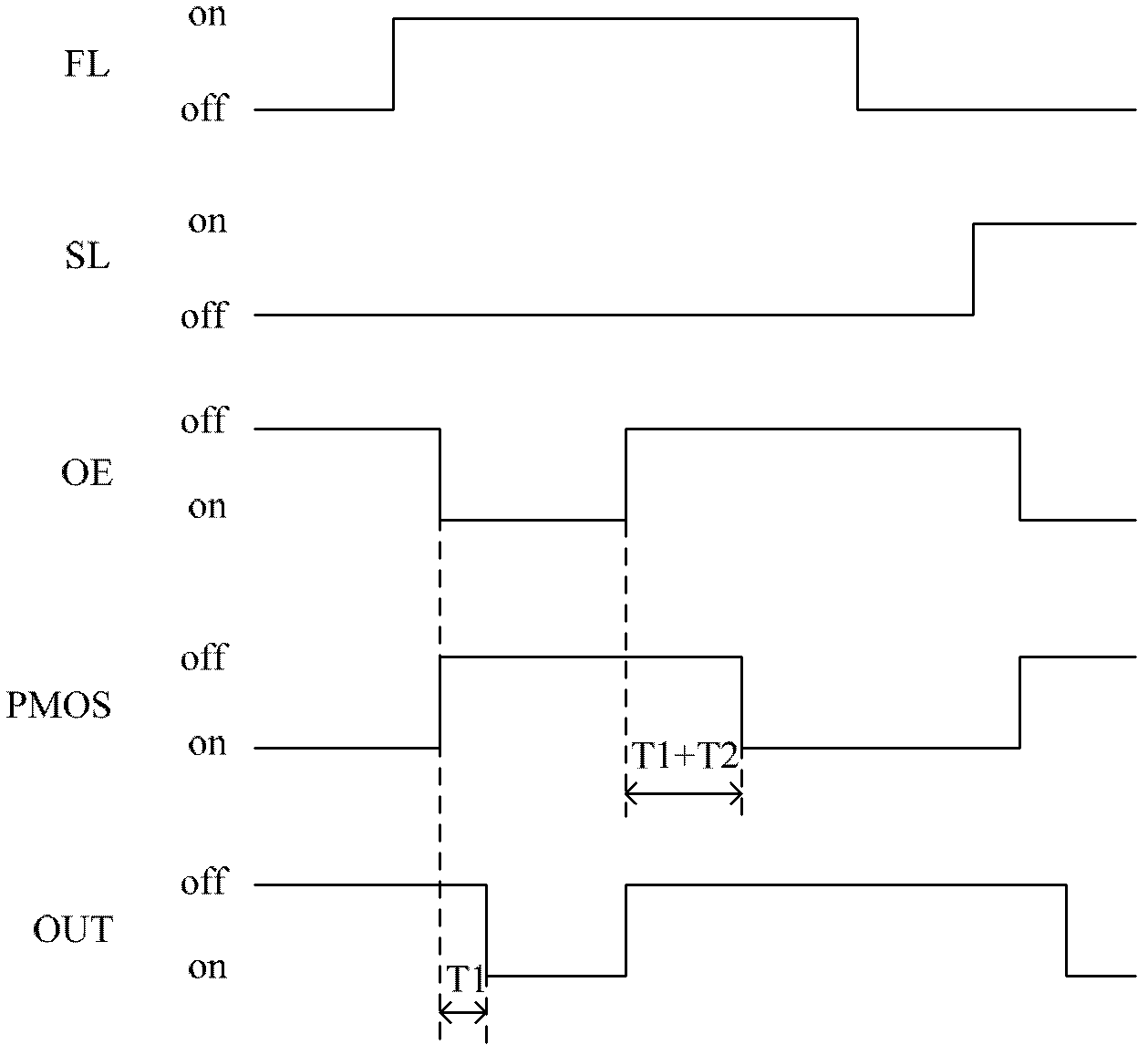

[0023] Timing control module 101, the input end is connected with the enable signal end of external main control device 400, and the first output end is connected with the enable end of drive circuit module 300, is used for the enable control signal output from external main control device 400 Timing processing is performed, and the working state of the driving circuit module 300 is controlled through the first output terminal. ...

Embodiment 2

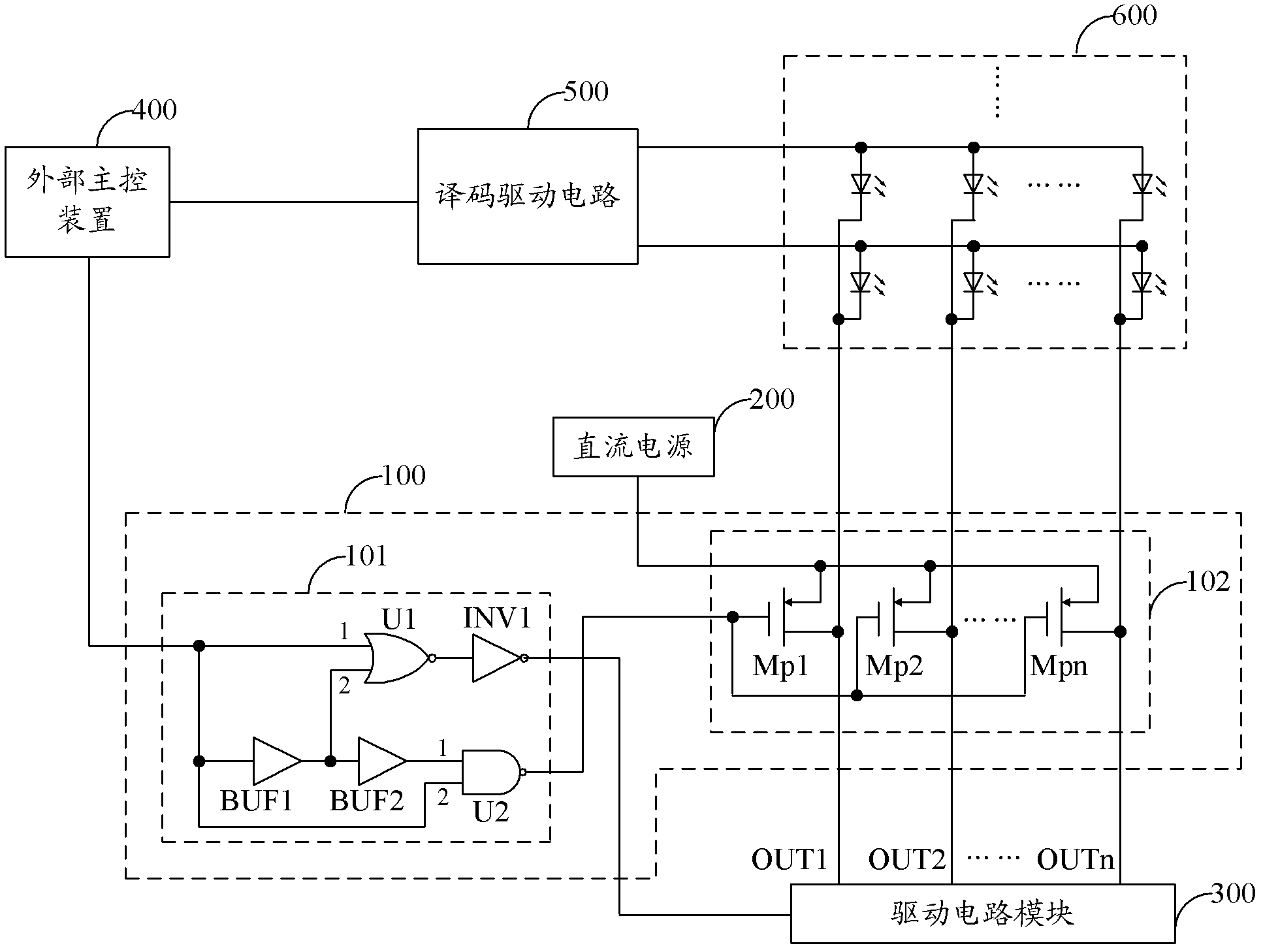

[0027] figure 2 An example circuit structure diagram of the LED display screen blanking control circuit provided by the second embodiment of the present invention is shown. For the convenience of explanation, only the parts related to the second embodiment of the present invention are shown, and the details are as follows:

[0028] As an embodiment of the present invention, the timing control module 101 includes:

[0029] The first NOR gate U1, the first inverter INV1, the first buffer BUF1, the second buffer BUF2 and the NAND gate U2;

[0030] The first input terminal 1 of the first NOR gate U1 is the input terminal of the timing control module 101, the output terminal of the first NOR gate U1 is connected to the input terminal of the first inverter INV1, and the output terminal of the first inverter INV1 is the first output terminal of the timing control module 101, the input terminal of the first buffer BUF1 is connected to the first input terminal 1 of the first NOR gate...

Embodiment 3

[0040] Figure 4 An example circuit structure diagram of the LED display screen blanking control circuit provided by the third embodiment of the present invention is shown. For the convenience of description, only the parts related to the third embodiment of the present invention are shown, and the details are as follows:

[0041] As an embodiment of the present invention, the timing control module 101 includes:

[0042] The second NOR gate U3, the second inverter INV2, the third buffer BUF3, the fourth buffer BUF4 and the AND gate U4;

[0043] The first input terminal 1 of the second NOR gate U3 is the input terminal of the timing control module 101, the output terminal of the second NOR gate U3 is connected to the input terminal of the second inverter INV2, and the output terminal of the second inverter INV2 is the first output terminal of the timing control module 101, the input terminal of the third buffer BUF3 is connected to the first input terminal 1 of the second NOR ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com