Working cylinder integrated with control valve and high-power hydraulic spring operating mechanism

A technology of hydraulic spring and operating mechanism, which is applied to high-voltage air circuit breakers, high-voltage/high-current switches, electrical components, etc., to achieve the effect of improving mechanical firmness, sealing reliability and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

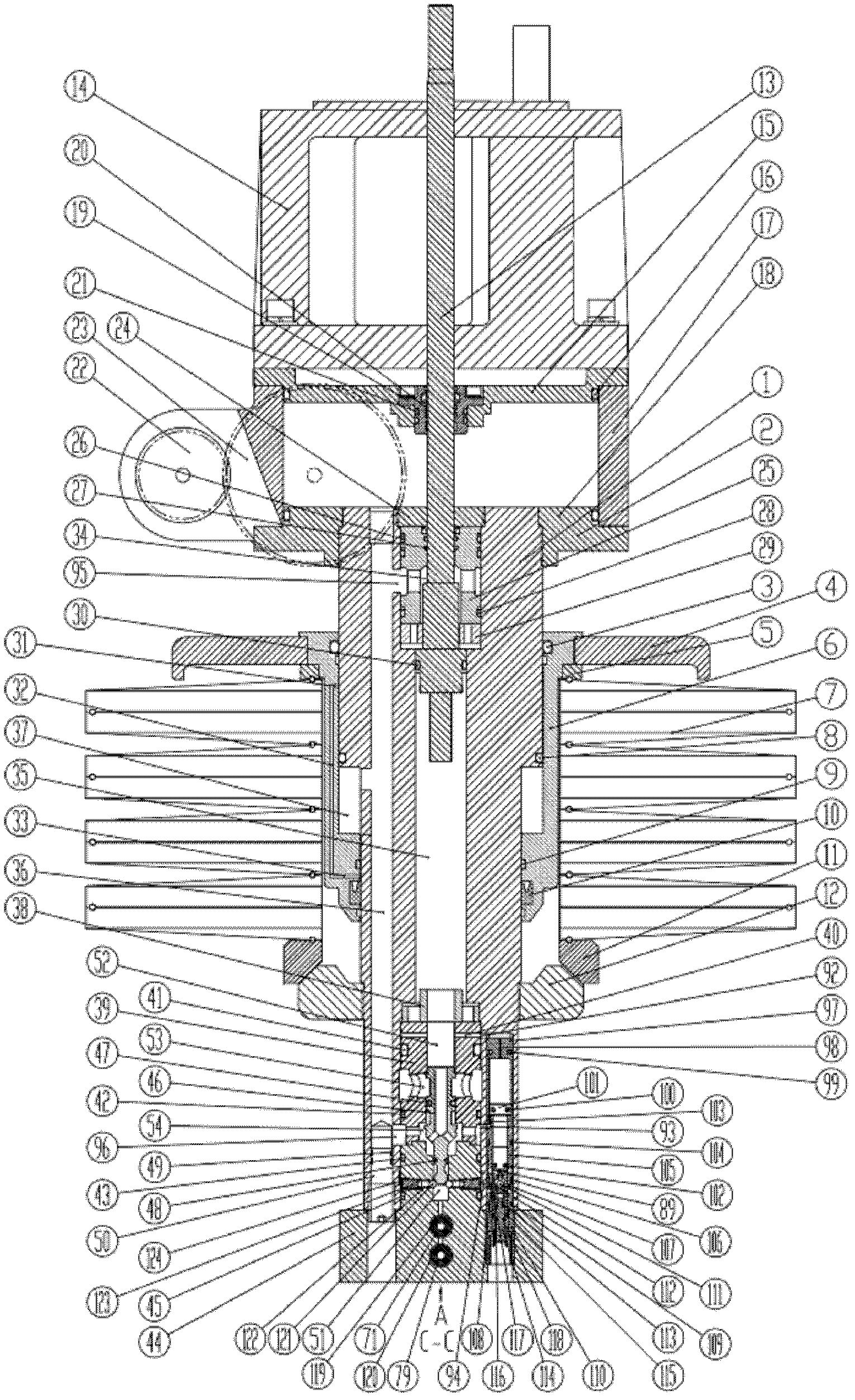

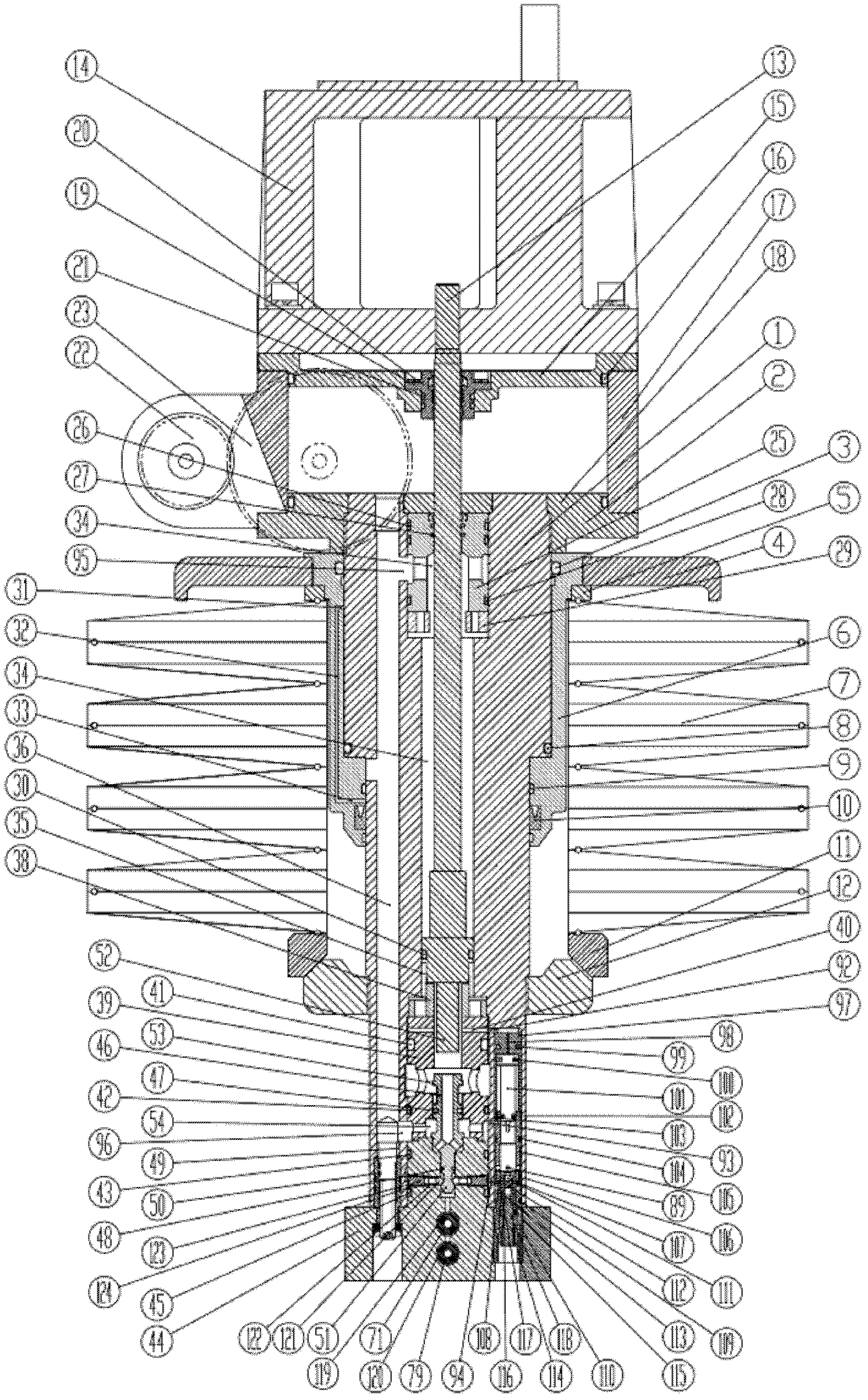

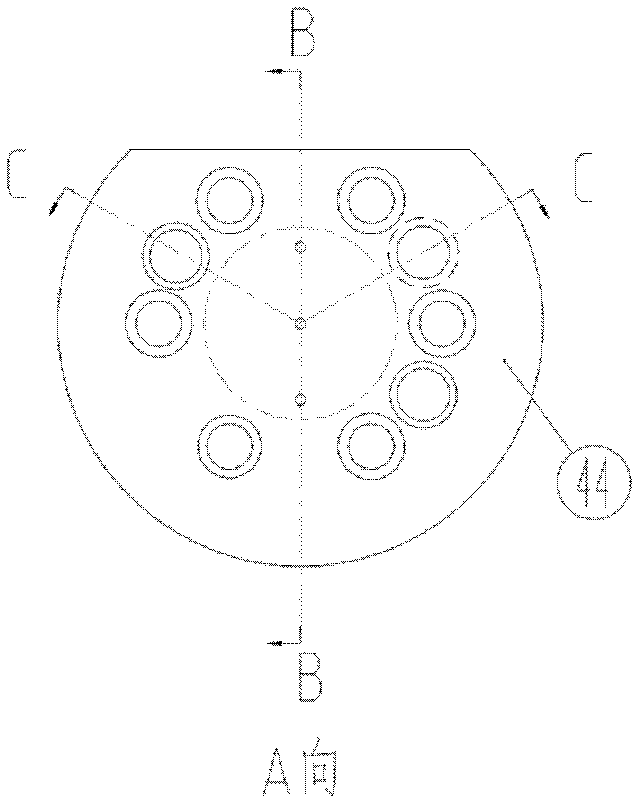

[0032] The high-power hydraulic spring operating mechanism of the present invention includes a working cylinder module, an energy storage module, a control valve module, and a fuel tank module; Both the valve module and the fuel tank module are directly connected with the working cylinder 1 in the working cylinder module and work together. The coaxial center of the energy storage module is set outside the working cylinder module and fixed, and the fuel tank module is fixed on the upper end surface of the working cylinder module. The valve module is integrated in the working cylinder at the bottom of the working cylinder module.

[0033] The working cylinder module is based on the working cylinder 1 (see figure 1 , Pic 4-1 ), the working cylinder 1 is a stepped cylinder, the center is provided with a cylinder center hole 88, the cylinder center hole 88 is a through hole of unequal diameter, the cylinder center hole 88 wears the piston rod 13, and the piston rod 13 is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com