Multipole direct-current contactor

A DC contactor and multi-pole technology, applied in the direction of relays, electromagnetic relays, detailed information of electromagnetic relays, etc., can solve the problems of large volume, high power consumption of electromagnetic coils, etc., achieve small volume, compact structure, and solve the problem of excessive volume Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

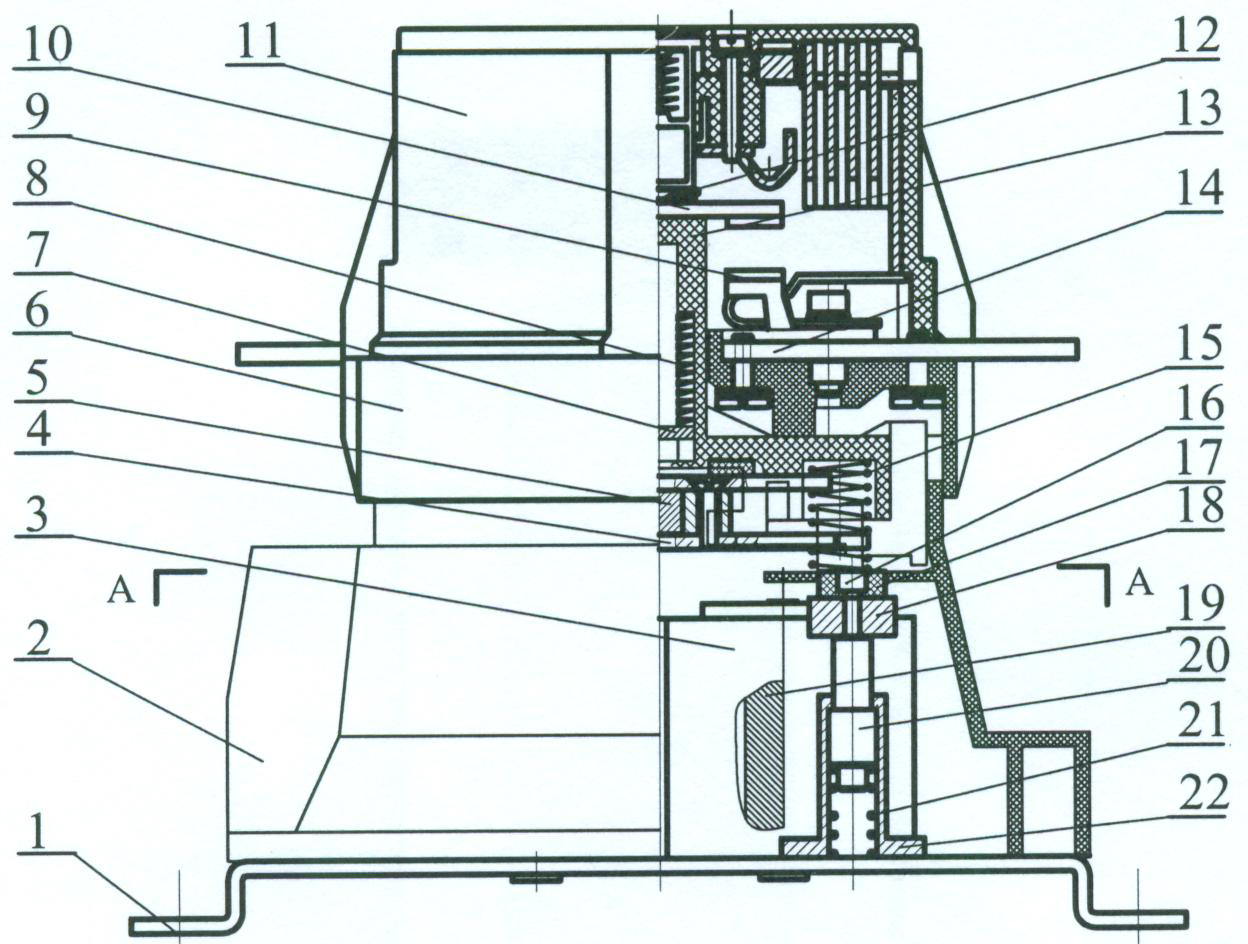

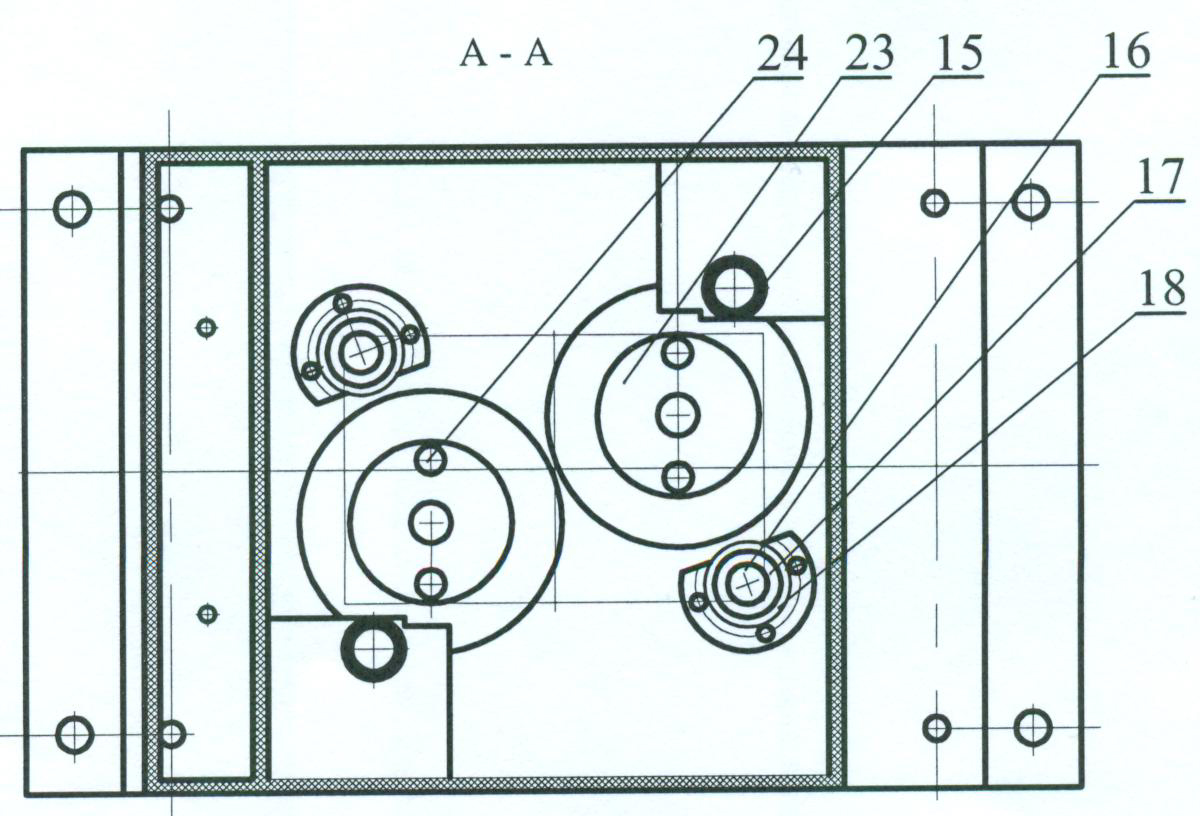

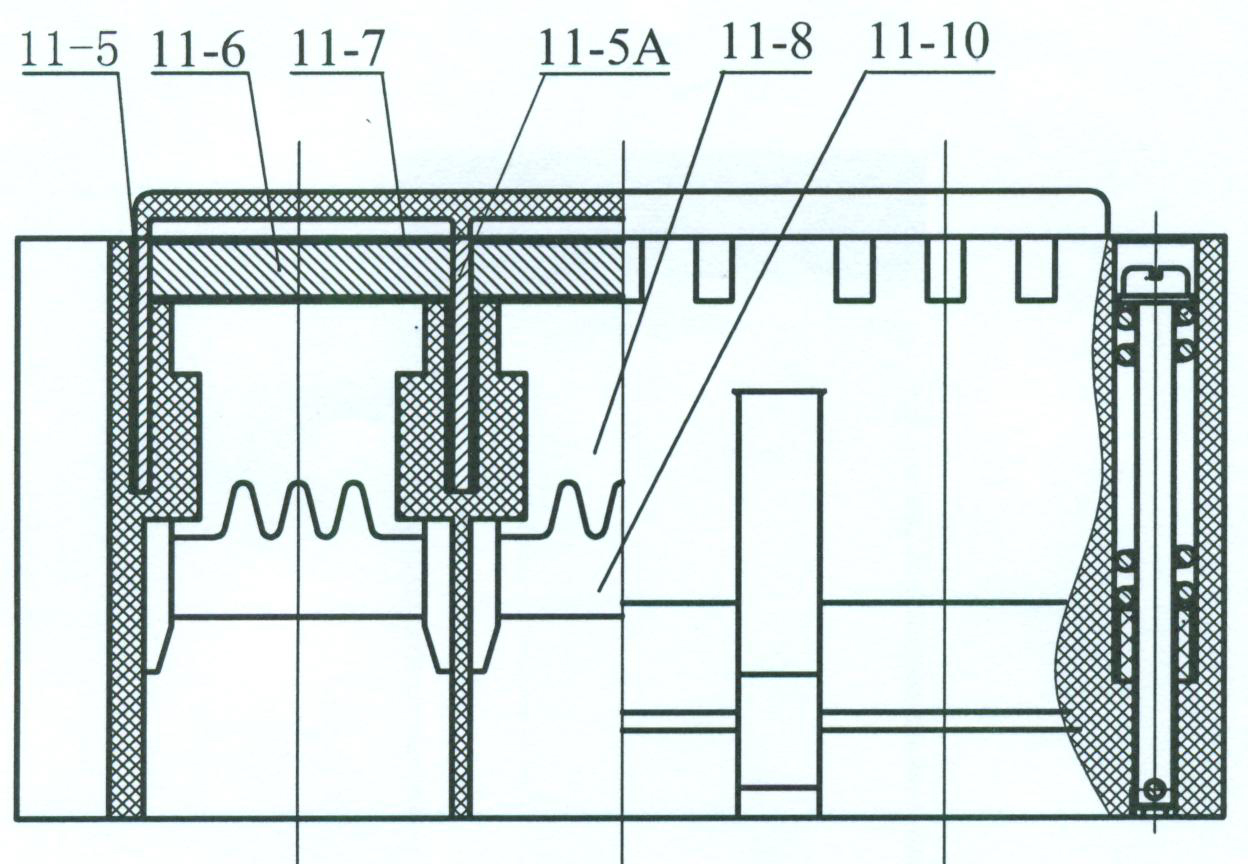

[0014] according to Figure 1~3 The specific structure of the present invention will be described in detail. The multi-pole DC contactor includes three parts: electromagnetic mechanism, arc extinguishing chamber and contact system. The electromagnetic mechanism is mainly composed of a coil 3, an iron core 19, an armature 4, a base plate 1, a booster magnet 18, a magnetic isolation pad 17, a guide rod 20, a spring 21, a guide seat 22, and the like. The arc extinguishing chamber 11 mainly includes a built-in arc extinguishing grid 11-8, an arc strike plate 11-10, a permanent magnet 11-6, a magnetic guide plate 11-5, and a heat insulating sleeve 11-7. The specific structure of the built-in permanent magnet magnetic blowing arc extinguishing structure of the arc extinguishing chamber 11 has been applied for the Chinese patent "DC contactor arc extinguishing device" at the same time. The structure of the arc extinguishing chamber 11 in the drawings of this embodiment is a three-p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com