Adjustable location lockout clamp

An adjustable and clamping technology, which is applied in the direction of switchgear and electrical components, can solve the problems of staff's lack of safety awareness, jamming of the baffle opening connecting rod, and accidental contact with the baffle push-pull mechanism, etc., to achieve standardization Work level, avoid personal electric shock, ensure personal safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

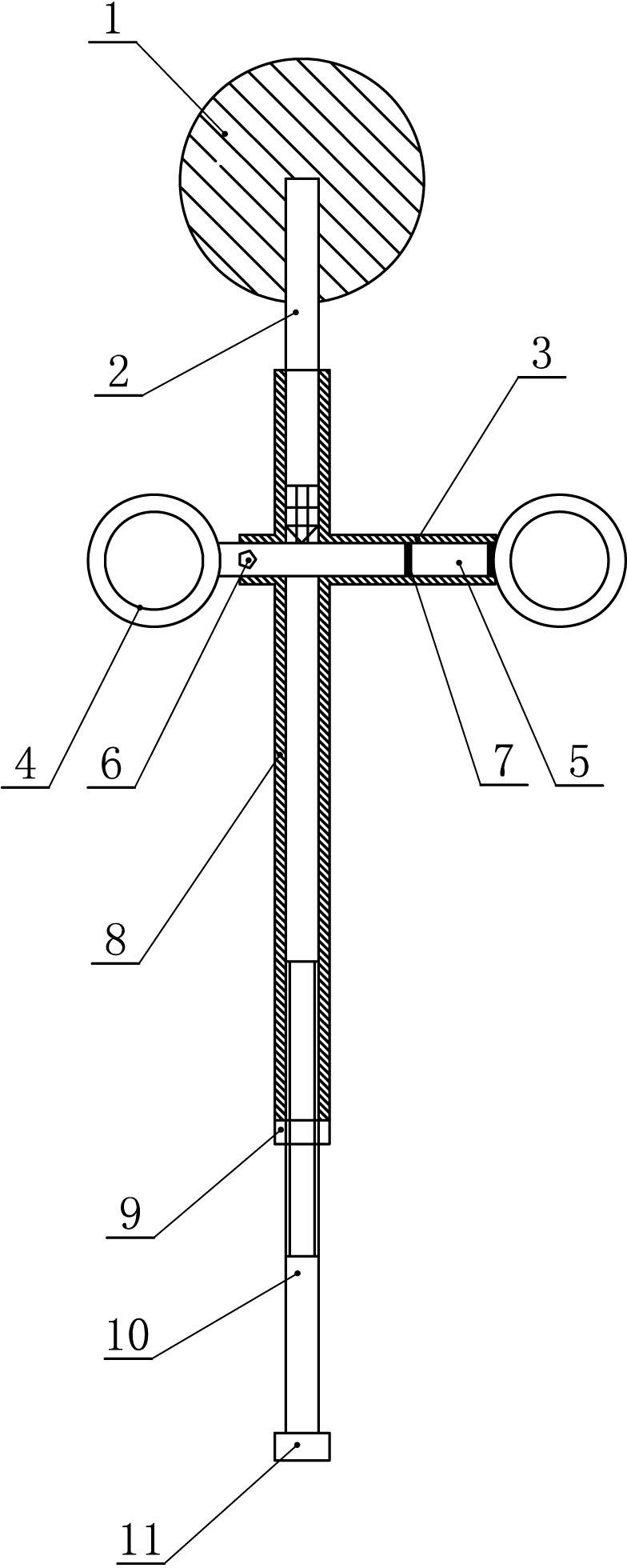

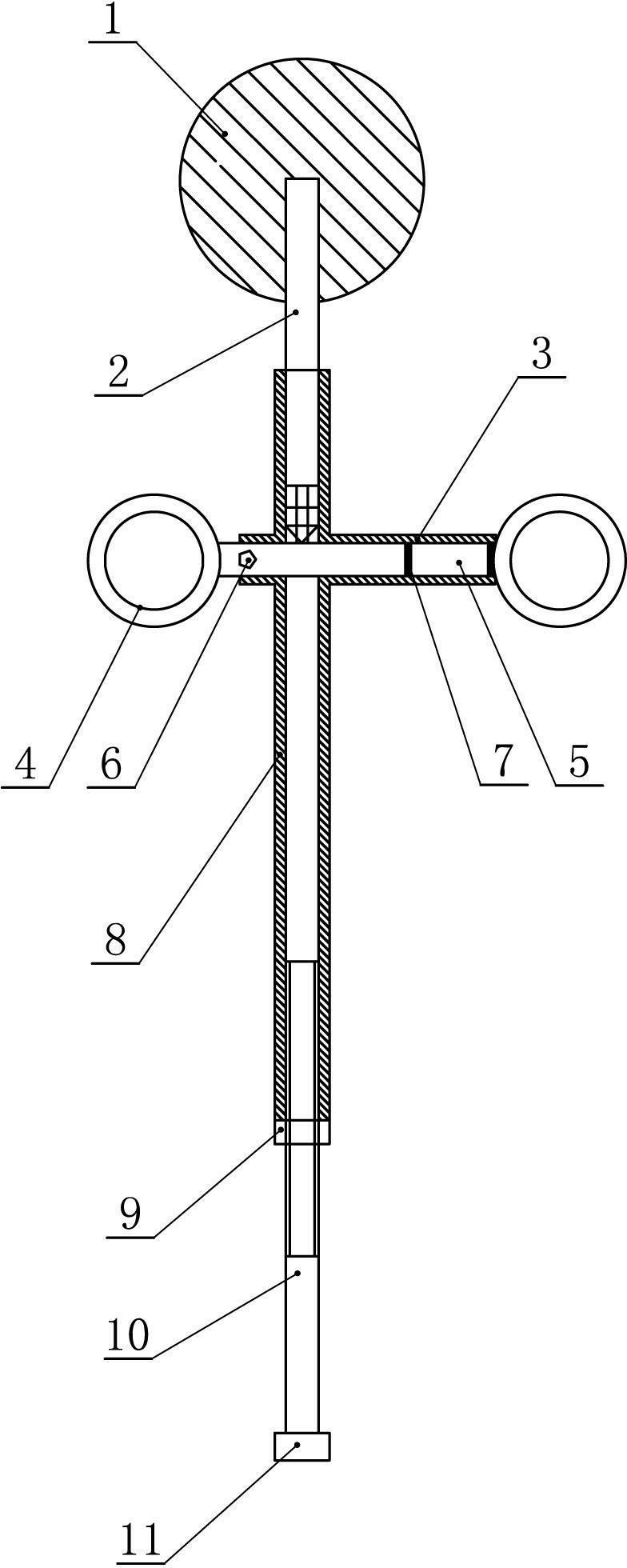

[0014] The structure of the present invention is as figure 1 As shown, an adjustable positioning locking fixture, including a positioning rod 8, is characterized in that: a positioning tube 3 is arranged on the left and right sides of the positioning rod 8, an adjusting screw 5 is installed on the ferrule 4, and the adjusting screw 5 is sleeved on the positioning tube 3 On, the lower end of the positioning rod 8 is screwed to the adjusting screw rod 10 . According to the adjustable positioning and locking jig, it is characterized in that: the upper end of the positioning rod 8 is screwed to the handle screw 2, and the insulating handle 1 is installed on the handle screw 2. According to the adjustable positioning and locking fixture, it is characterized in that: a fixing nut 9 is installed on the adjusting screw 10 , and the fixing nut 9 is screwed t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com