Transformer substation assembled type cable groove body and cable channel system thereof

An assembled, substation technology, applied in cable installation, ground cable installation, etc., can solve the problems of high resource cost, shortened construction period, and high time cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

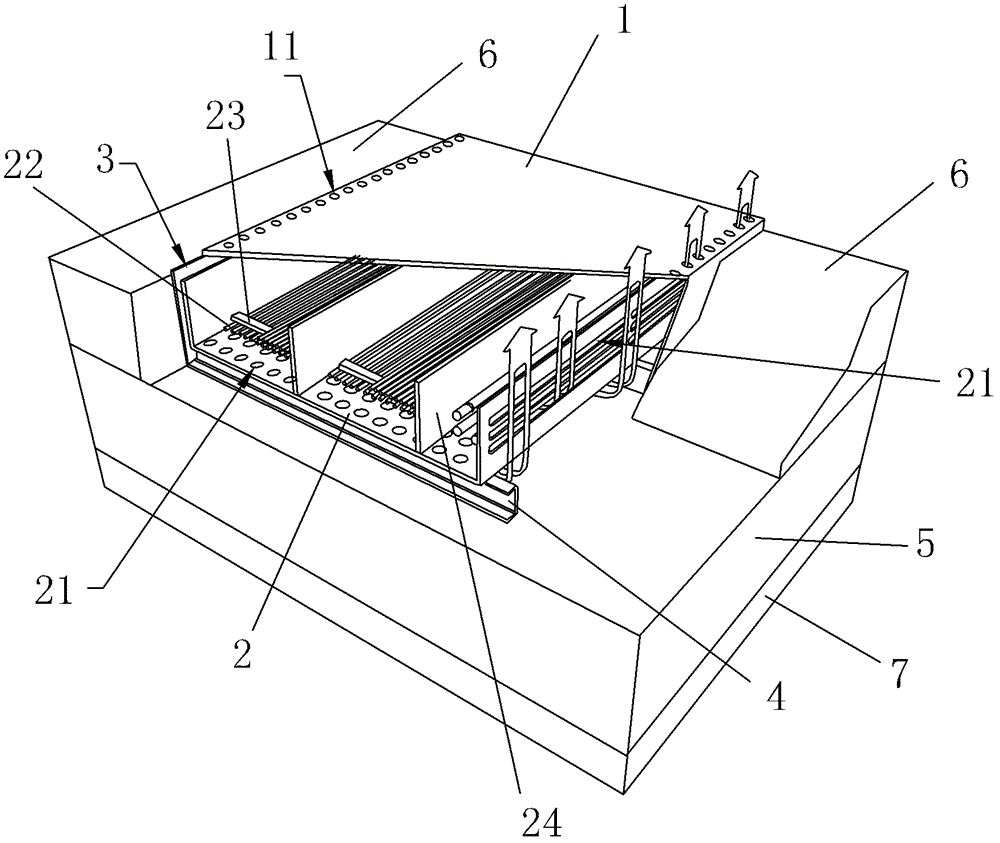

[0021] Embodiment 1: Assembled cable trench body in substation, such as figure 1 As shown, it consists of a series of U-shaped waterproof ditch bodies connected in turn. Each U-shaped ditch body 1 is provided with a U-shaped moisture-proof support body 2 in the inner cavity, U-shaped ditch body 1 and U-shaped ditch body. The moisture-proof support bodies 2 are snapped together in opposite directions, and the middle part forms a cable laying channel. The front and rear ends of the U-shaped waterproof ditch body are respectively provided with a flange section and a concave joint groove that can be connected back and forth to form a front and rear lap joint groove, and double P rubber strips are installed between the front and back ditch bodies. The U-shaped ditch body 1 and the U-shaped moisture-proof support body 2 are made of C30-C40 reinforced concrete or steel fiber concrete (appearance grade of fair-faced concrete).

[0022] In order to make reasonable use of the space, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com