Battery with degassing system and method for dissipating emerging substances

A technology for exhaust systems and battery packs, applied in battery pack components, exhaust plug devices, secondary battery manufacturing, etc. Reduced weight, simplified adaptability, cost savings on installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

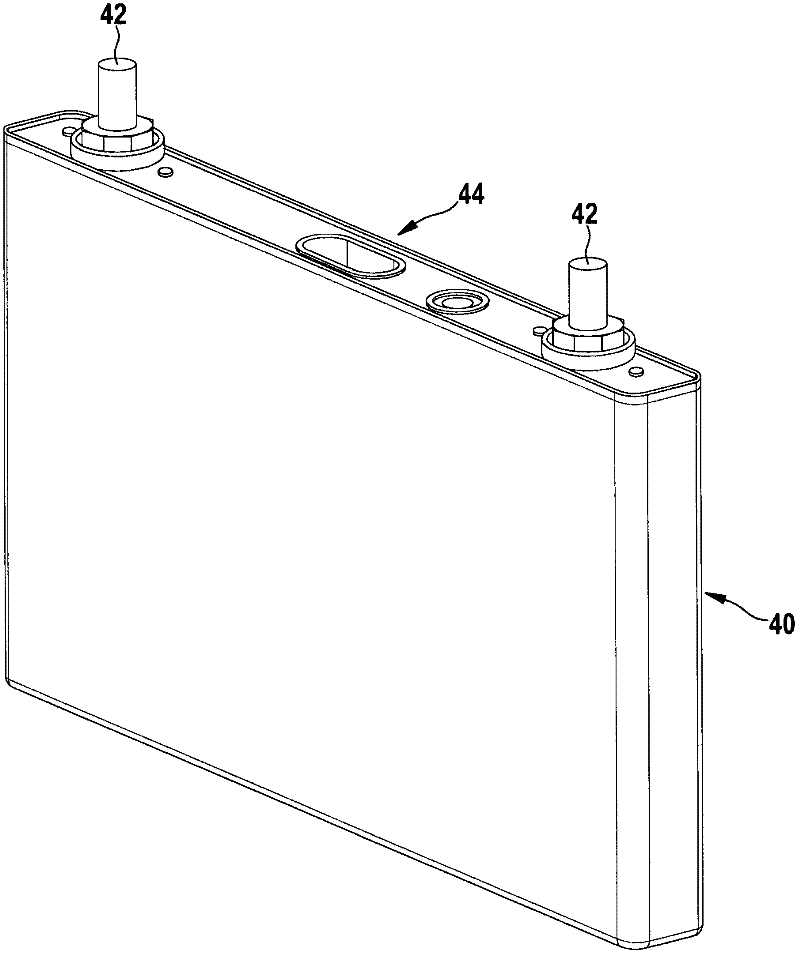

[0029] exist figure 1 A conventional battery cell 40 according to the prior art is shown in . The upper surface thereof is provided with a battery terminal 42 and a top-mounted exhaust port 44 . If the battery pack contains multiple cells, a complex piping system is required to conduct the gas and electrolyte from the exhaust port.

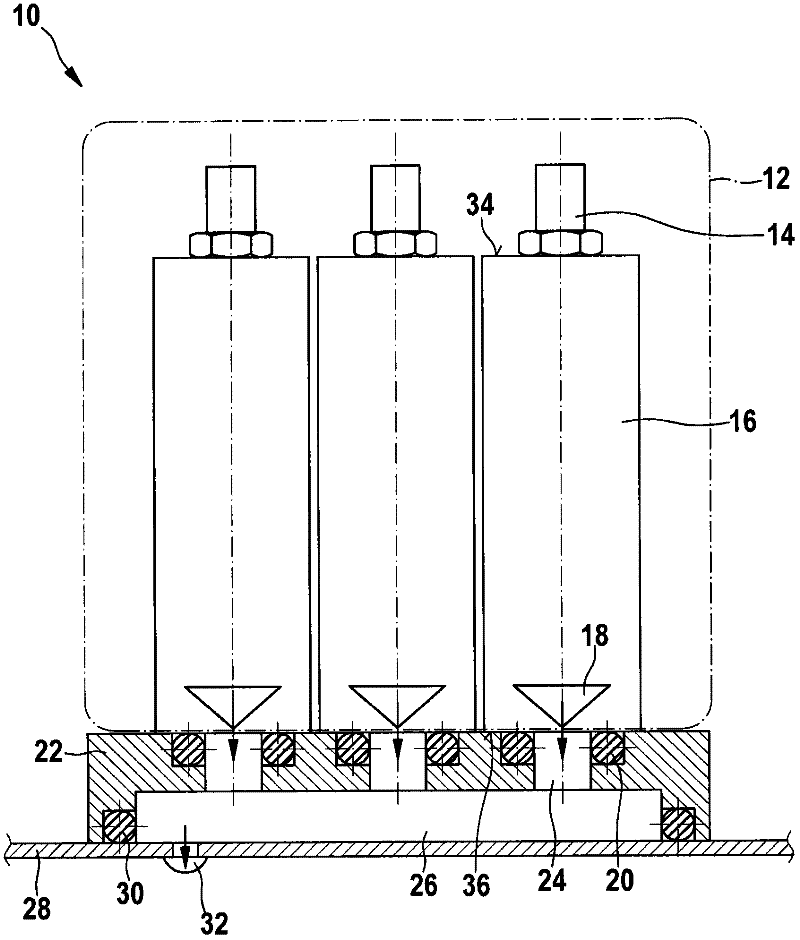

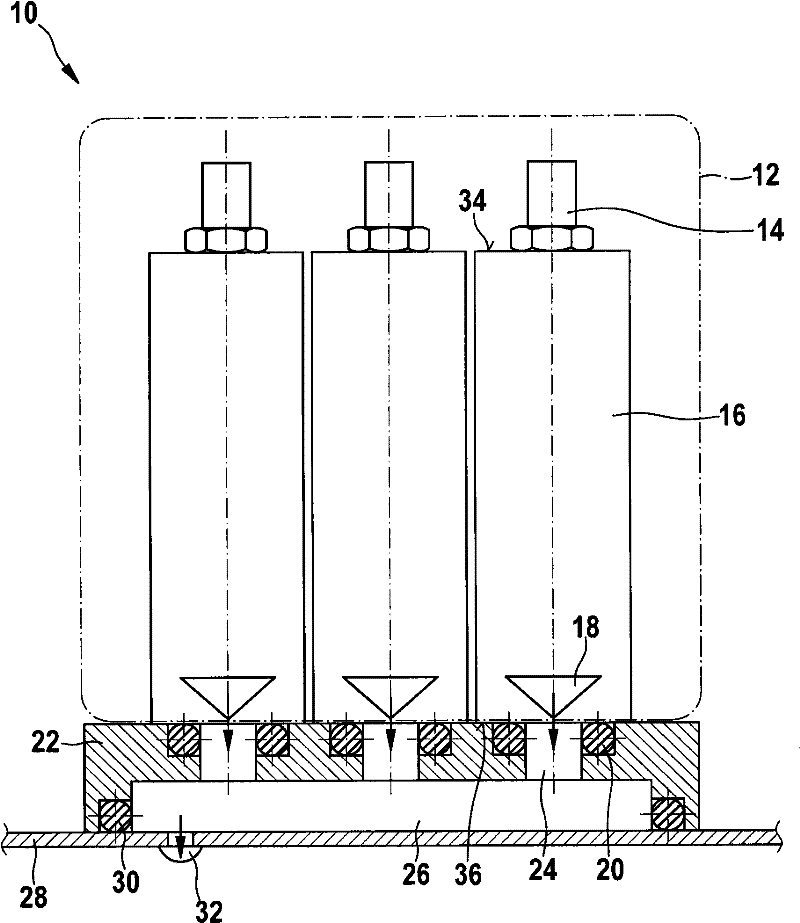

[0030] figure 2 A cross-sectional view of a battery pack 10 with an exhaust system according to the present invention is shown. The base plate 22 is mounted on the shell plate 28 . A shell seal 30 is provided between the shell 28 and the base plate 22 . Fastened to the base plate 22 is the battery module 12 , which here includes three battery cells 16 . Each battery cell 16 has a battery terminal 14 on an upper side 34 . Each battery cell 16 is provided with a lower air outlet 18 on a lower side 36 opposite to the upper side 34 . The vent opening 18 of the battery cell 16 is here directly sealed against the base plate 22 by an O-ring 20 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com