Method for processing whole-grain biscuit

A processing method, the technology of whole grains, applied in the field of biscuit processing, can solve the problems that the whole cornmeal and whole grains cannot be widely used, the nutritional value of biscuits is single, and the degree of puffing is limited, so as to improve the rough taste, enrich the nutritional value, and match reasonably Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

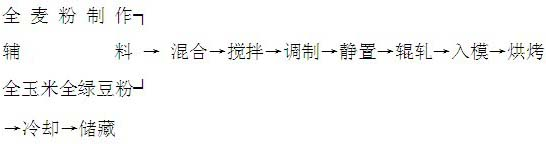

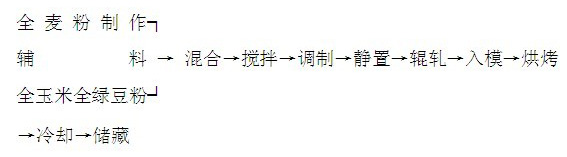

[0050] like figure 1 As shown, the processing flowchart of the whole grain biscuit specifically includes the following steps:

[0051]1) Production of whole wheat flour: dehulling the wheat grains and screening, separating the bran from the debraned wheat grains, processing the debranized wheat grains into flour, superfinely pulverizing the bran, and then pulverizing the flour and superfinely pulverizing The bran is mixed through a 100-mesh sieve to obtain whole wheat flour.

[0052] 2) Production of whole corn and whole mung bean flour;

[0053] ① Select mung beans and corn with plump appearance and no impurities. Soak mung beans in water at 15°C for 16 hours; soak corn in water at 15°C for 6 hours;

[0054] ② Add water at a weight ratio of 1:5, grind the soaked mung beans with a steel mill to produce mung bean milk, and keep the bean dregs; add water at a weight ratio of 1:3, and grind the soaked corn with a steel mold crushed to form corn steep liquor, and the corn dregs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com