Composite type complex organ precursor three-dimensional controlled forming system with multiple sprayers

A multi-nozzle, composite technology, applied in the direction of prosthesis, medical science, etc., can solve the problems of low molding efficiency, large connection error of nozzle jetting effect, and inability to control the number and precise position of cell printing, so as to improve the forming efficiency and improve The effect of forming precision and wide range of motion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

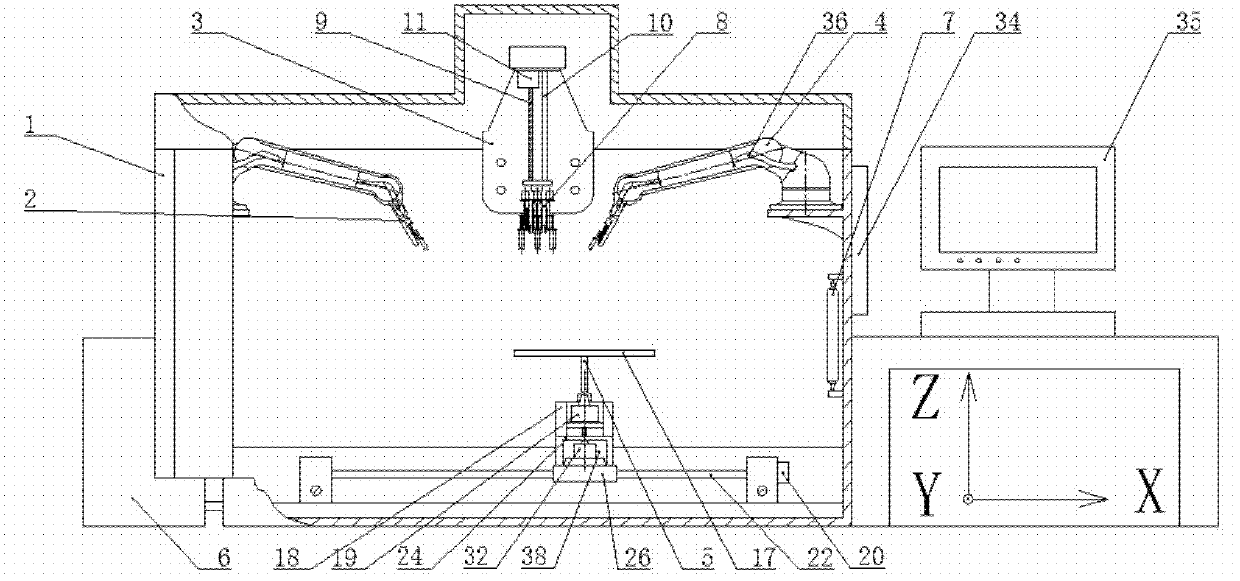

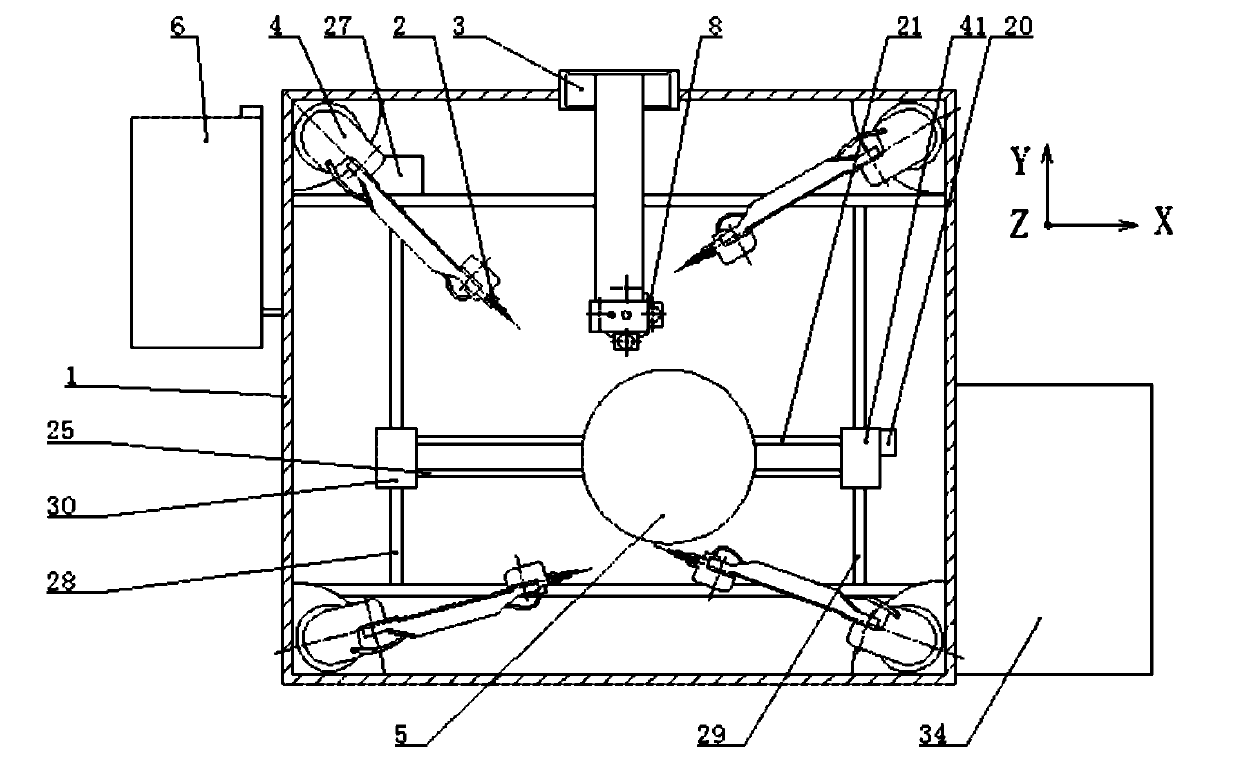

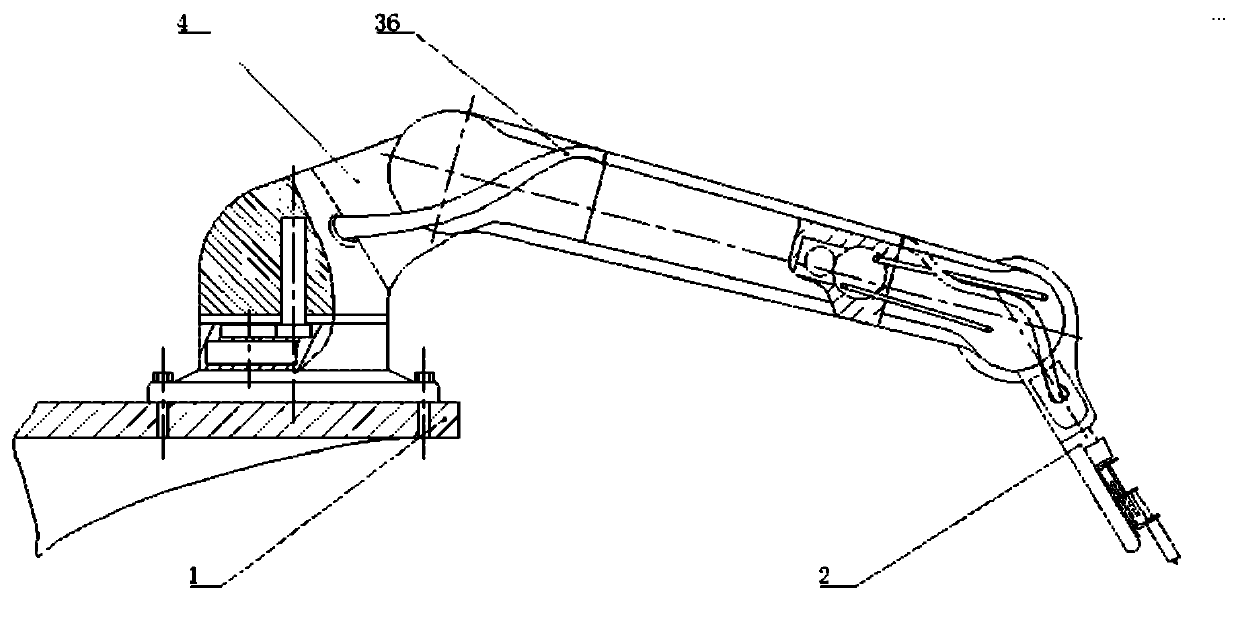

[0054] The specific structure, working principle and working process content of the present invention will be further described in detail below in conjunction with the accompanying drawings and implementation examples.

[0055] The composite multi-nozzle complex organ precursor three-dimensional controlled forming system designed by the present invention, such as figure 1 and figure 2 As shown, the system includes a box body 1, a fixed multi-nozzle spraying device, a free spraying device, a top support 3, a three-dimensional motion mechanism, a forming table 5, a temperature control and refrigeration device 6, a sterilization device 7 and a control system. The fixed multi-nozzle spraying device is fixed on the top center of the box body 1 through the top bracket 3. The connection mode between the top bracket 3 and the box body 1 is bolt connection, and the free-style spraying device is fixed on the side wall of the box body 1. In the present invention, the free-style Four in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com