Forced lubrication device

A technology of lubricating device and lubricating box, applied in the field of metal drawing processing, can solve the problems of scratches, inability to form, lack, etc., and achieve the effect of reducing loss, ensuring quality, and easy adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the embodiments and accompanying drawings. The embodiments are only used to explain the present invention and do not constitute a limitation to the protection scope of the present invention.

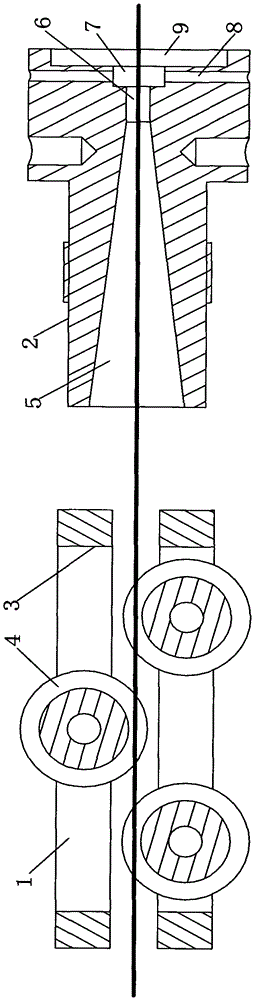

[0016] The forced lubricating device as shown in the accompanying drawings includes a lubricating box body 1 and a forced pipe 2 connected in the middle. The lubricating box body 1 is arranged at the front end of the forced pipe 2. The lubricating box body 1 includes a powder clamp 3 and three equal-diameter Rollers 4, the wire rod can pass between the rollers 4. The forced pipe 2 includes a conical inlet 5 , a working section 6 , a high-pressure section 7 , a vent hole 8 and a joint position 9 . The diameter of the working section 6 is 0.6-0.8mm larger than the diameter of the wire. The conical inlet 5 is set at the front end of the working sect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com