Die assembly for forming torsional lock bolt

A technology of die combination and anti-loosening bolts, applied in the direction of bolts, manufacturing tools, threaded fasteners, etc., can solve the problems of high cost, poor product accuracy, low processing efficiency, etc., and achieve high-speed production, good efficiency, high The effect of quality production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

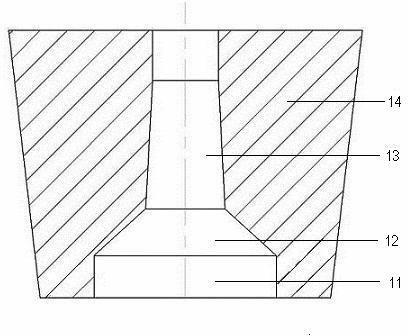

[0029] The present invention will be described in further detail below in conjunction with specific examples.

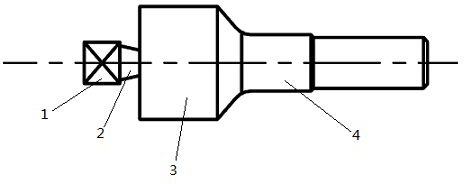

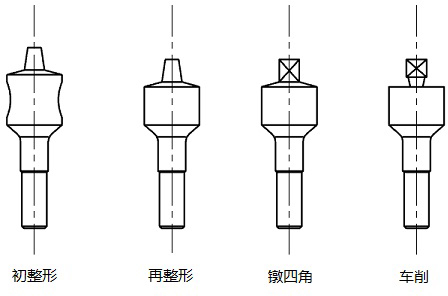

[0030] like figure 2 As shown, the processing method of the torsional shear anti-loosening bolt of the present embodiment, its specific steps are carried out as follows:

[0031] Firstly, the process before hot heading is carried out, pickling, phosphating, spinning, blanking, chamfering and shrinking of the raw materials are carried out to obtain the blank to be shaped. Among them, the raw materials are pickled and phosphating, the purpose of which is to prepare for the shrinking process; wire drawing, that is, processing the optimal size according to product characteristics; chamfering, that is, lathe deburring to make the material fit into the mold better; The rod is ready for the following thread rolling process.

[0032] Then, carry out primary shaping, heat the billet, the heating temperature is 800~1000°C, transfer the heated billet to the No. 1 mold for ex...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap