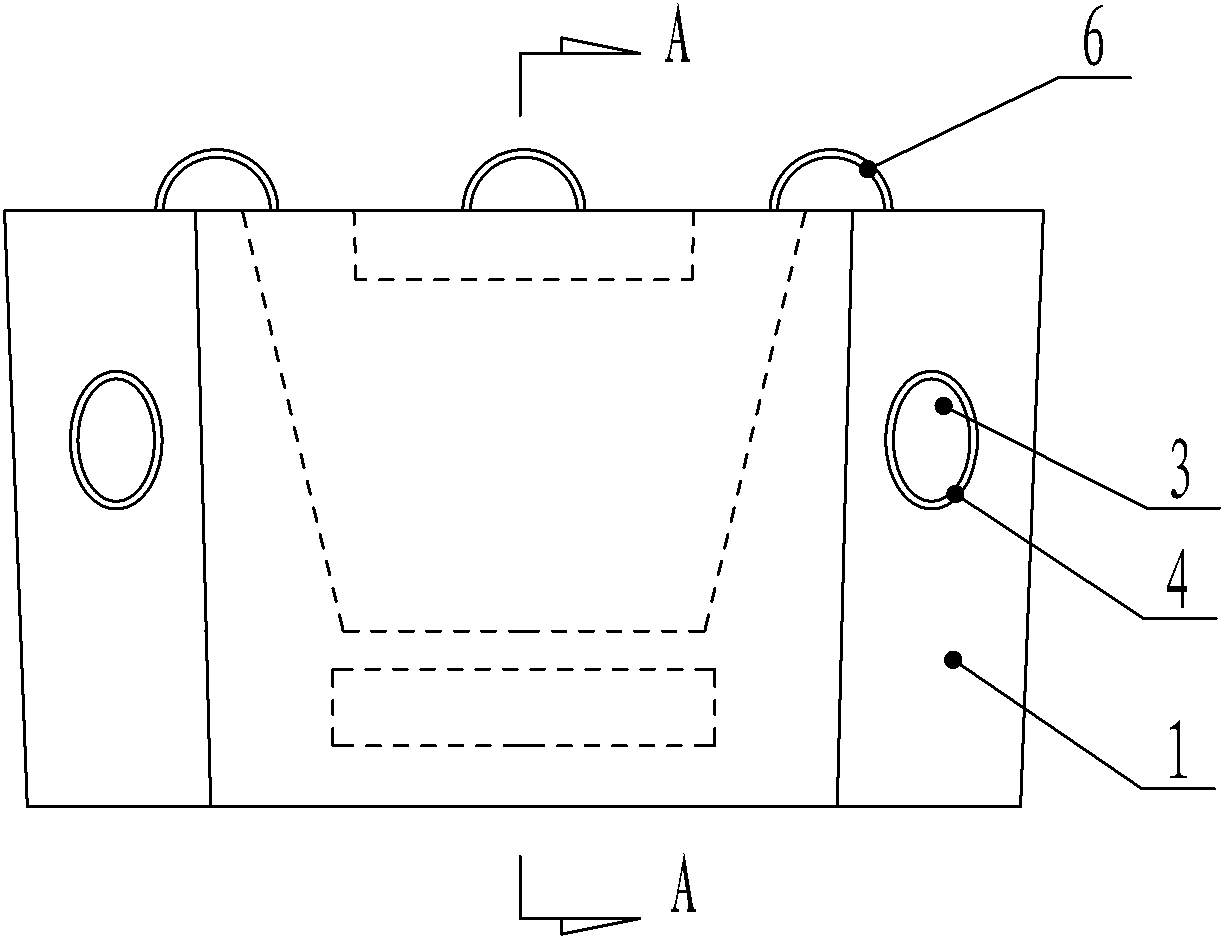

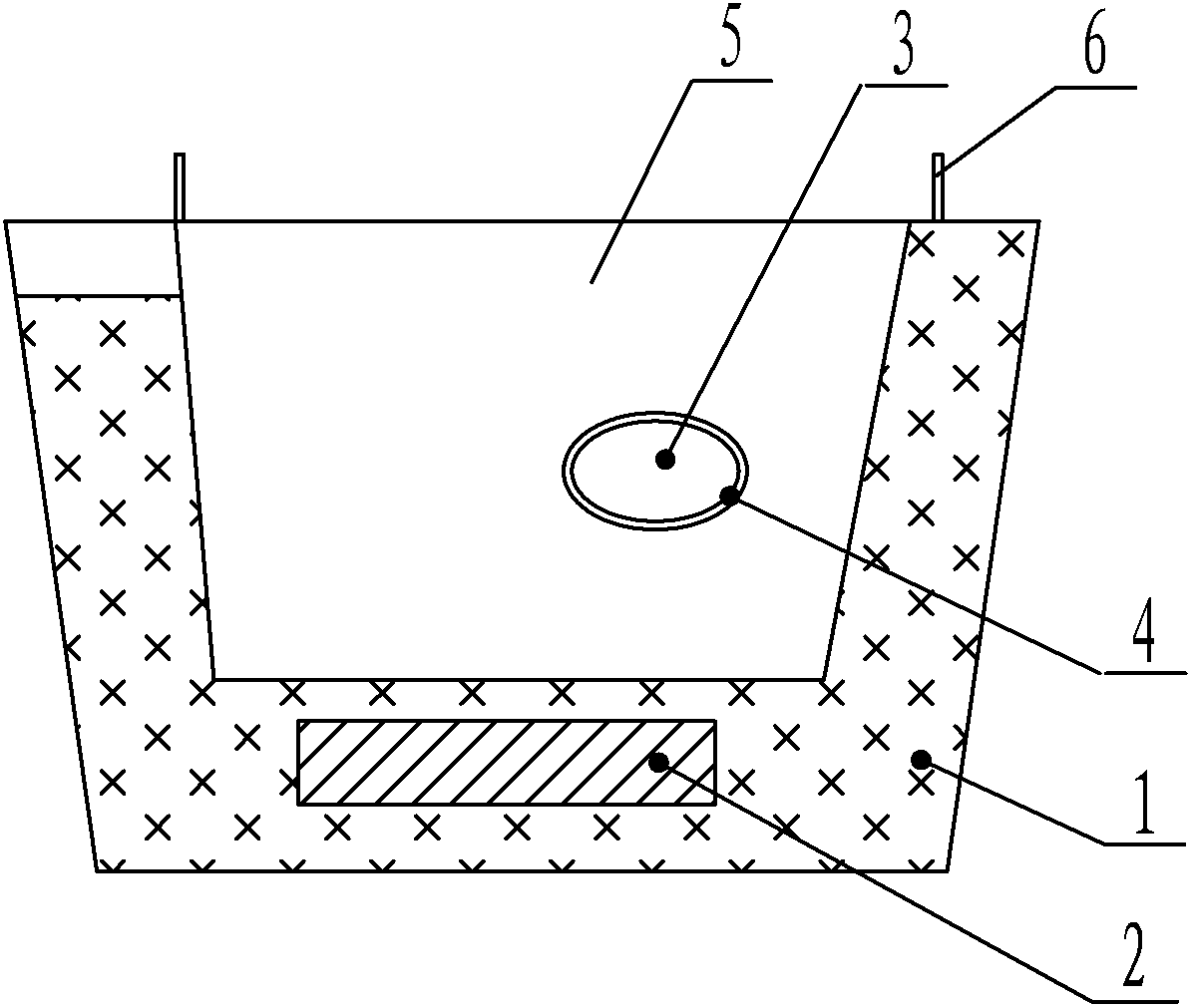

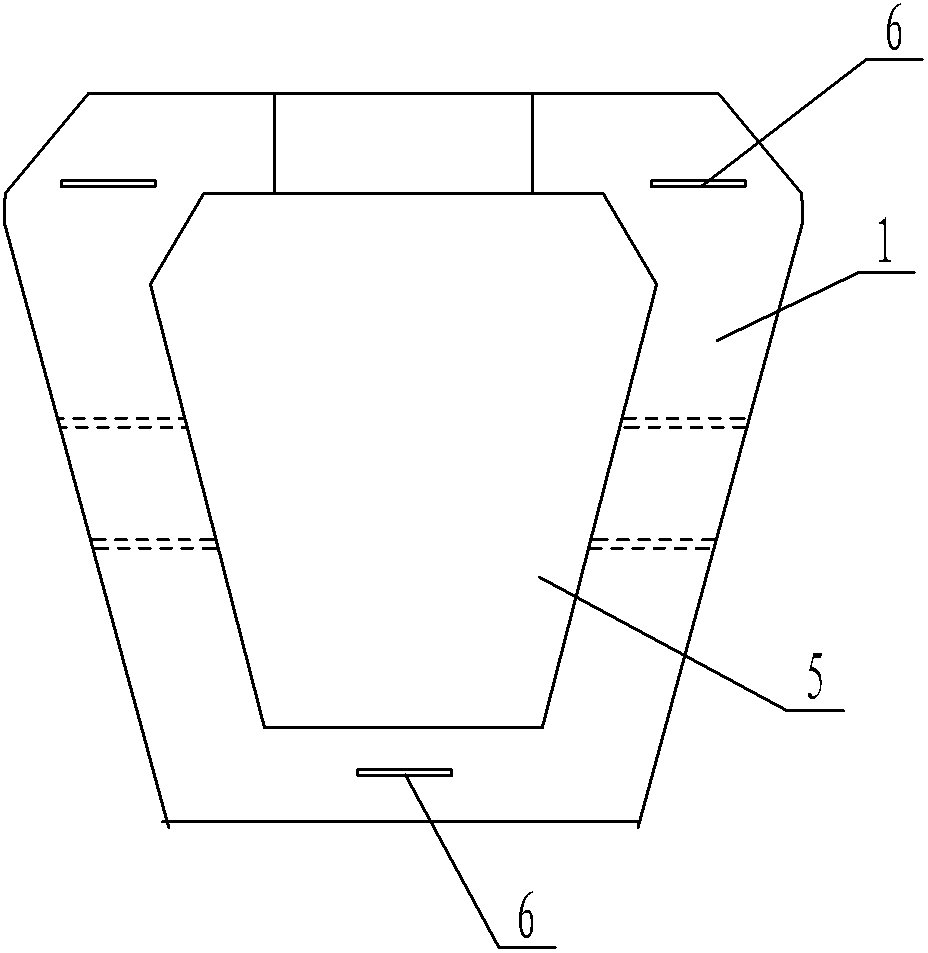

Novel composite current stabilizer and manufacturing method of the novel composite current stabilizer

A flow stabilizer and a new type of technology, applied in the new composite flow stabilizer and its production field, can solve the problem of loss of flow control effect, low service life of flow control device, anti-erosion and anti-scour service life of slag retaining wall and impact plate Low problems, to achieve the effect of increasing the number of pouring furnaces, improving the pass rate, improving the effect of flow control and slag blocking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053]The material of the impact plate and casing brick embedded in the novel composite current stabilizer of the present invention is aluminum-magnesium carbon, and the material of the body is magnesium-aluminum-chrome castable, wherein the impact plate and casing brick are mainly composed of the following materials by weight percentage: Brown corundum 80%, of which 5-3mm accounted for 25%, 3-1mm accounted for 29%, 0.075-1mm accounted for 8%, 0.075mm or less accounted for 18%; fused magnesia particle size ≤ 1mm 8%, graphite 2 %, carbon black 2.5%, aluminum powder or silicon powder 4%, binder 3.5%.

[0054] The body is mainly composed of the following materials by weight percentage: high-purity magnesia 51%, of which: 28% of particle size 8-5mm, 15% of 5-3mm, 8% of 3-1mm; brown corundum 18%, of which: 8% of particle size is 3-1mm, and 10% of particle size is less than 1mm; 6% of chrome concentrate particle size ≤1mm, 15% of fused magnesia 180 mesh, 3% of silicon micropowder, 2...

Embodiment 2

[0076] The impact plate and casing brick embedded in the new composite current stabilizer of the present invention are made of aluminum-magnesium carbon, and the material of the body is magnesium-aluminum-chrome castable, wherein the impact plate and casing brick are mainly composed of the following materials by weight percentage : Brown corundum 81%, of which: 5-3mm 24%, 3-1mm 30%, 0.075-1mm 7%, 0.075mm or less 20%, fused 97 magnesia particle size ≤ 1mm 8%, graphite 3% , 2% carbon black, 3% antioxidant, 3% binder.

[0077] The body is mainly composed of the following materials by weight percentage: high-purity magnesia 54%, of which: 29% of particle size 8-5mm, 17% of 5-3mm, 8% of 3-1mm; brown corundum 15%, of which: 7% with a particle size of 3-1mm, 8% with a particle size below 1mm; 6% of chrome concentrate with a particle size of ≤1mm, 15% of fused magnesia 180 mesh, 3% of silicon micropowder, 2% of refractory steel fiber, α-Al 2 o 3 5%, sodium tripolyphosphate 0.1 (addi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Body dense | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com