Reamer device for reaming sealing holes and bottom surfaces

A technology of sealing holes and reamers, which is applied in the direction of reaming devices, reaming devices, metal processing equipment, etc., can solve the problems of sealing holes and bottom surfaces of ignition seats, etc., and achieves reduced production labor intensity, compact structure, and strong practicability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

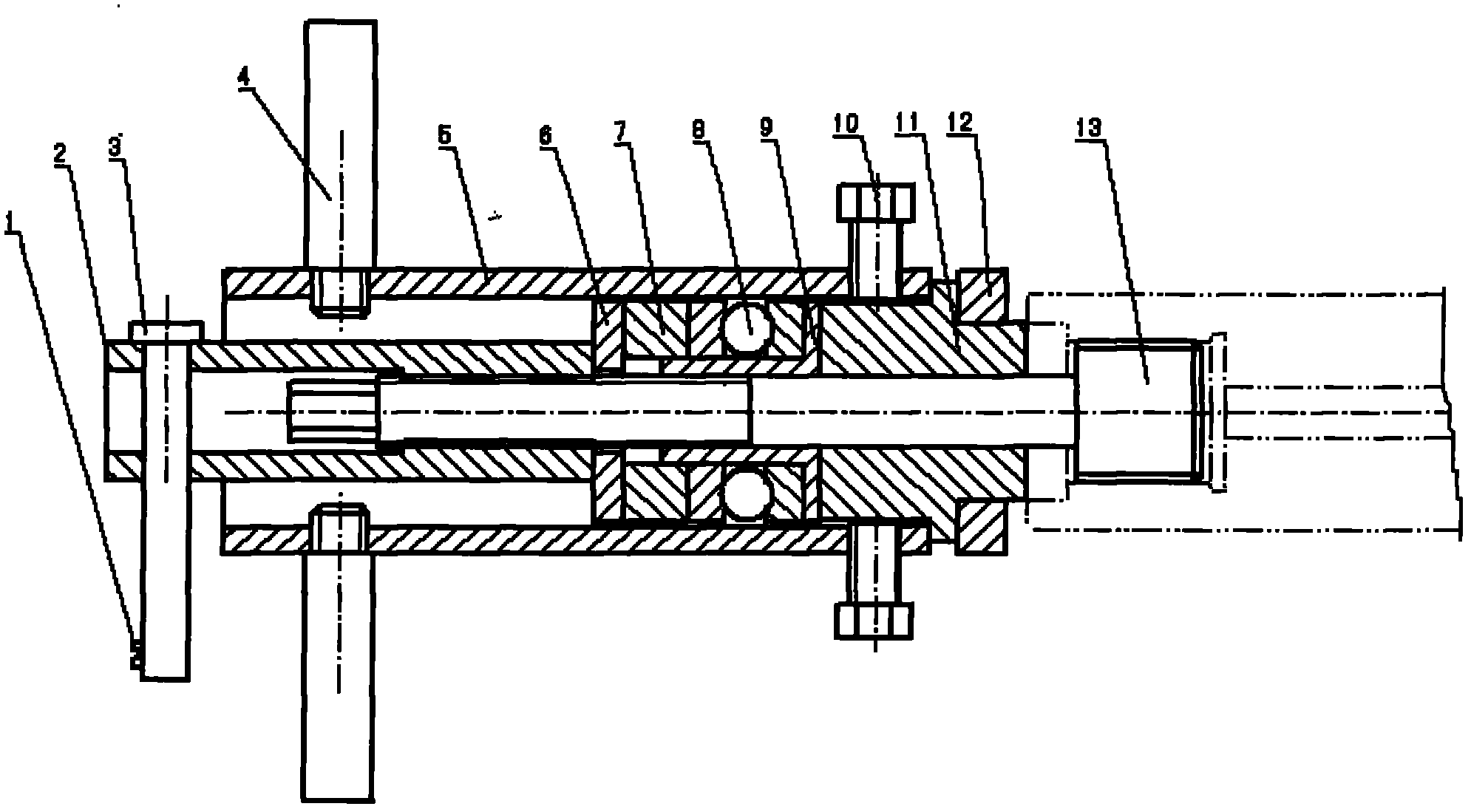

[0014] This eccentric fixture is divided into thirteen parts, such as figure 2 As shown, it includes screw 1, adjusting nut 2, screw rod 3, handle 4, sleeve 5, bearing cover 6, spacer 7, thrust ball bearing 8, bearing seat 9, bolt 10, reamer 11, adjustment piece 12, Screw 13.

[0015] First screw rod 13 front end external thread and internal thread on the workpiece are connected in place, then reamer 11, adjusting piece 12 is contained on the screw rod 13, reamer 11 and adjusting piece 12, adjusting piece 12 and screw rod 13 adopt shaft hole to cooperate. Then bearing seat 9, thrust ball bearing 8, spacer 7, and bearing cover 6 are mounted on the screw rod 13 in sequence, and are matched with the shaft hole of the screw rod 13, and are screwed and fixed by the adjusting nut 2 and the screw rod 13, the handle 4, the bolt 10 and the sleeve The barrel 5 is th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com