Plate compression device

A technology of pressing device and plate, applied in the direction of positioning device, clamping, supporting, etc., can solve the problems of low work efficiency and high labor intensity, and achieve the effect of simple structure, high degree of automation, convenient and quick operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

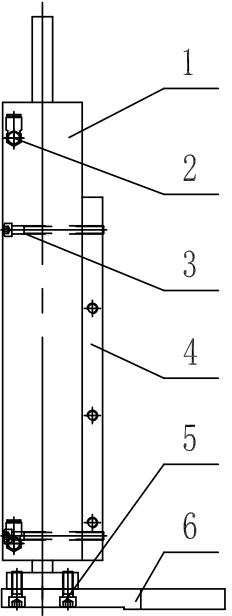

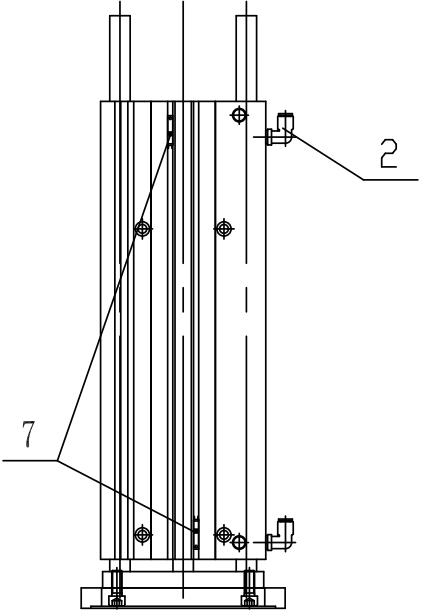

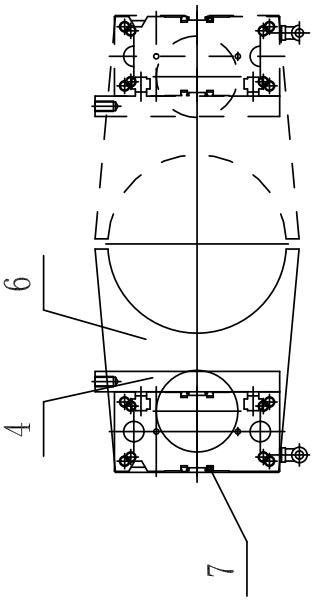

[0015] Such as Figure 1 to Figure 3 As shown, the plate pressing device of the present invention includes a long screw 3 on the mounting plate 4 with a guide rod cylinder 1, and the guide rod cylinder 1 is equipped with a right-angle quick change joint 2 and is installed in its groove. The upper and lower magnetic switches 7 of the band guide rod cylinder 1 are equipped with a semi-circular pressure plate 6 with a screw 5 at the lower end of the piston moving plate of the cylinder 1.

[0016] During actual work, the plate pressing device adopts the mounting plate 4 with a long screw 3 to dress the guide rod cylinder 1, and the lower end of the piston moving plate of the band guide rod cylinder 1 is equipped with a semi-circular pressing plate 6 with a screw 5. The guide rod cylinder 1 is equipped with a right-angle quick-change joint 2 f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com