Hydraulic transmission surface grinding machine

A surface grinder and hydraulic transmission technology, which is applied to the parts of grinding machine tools, grinding drive devices, grinding/polishing equipment, etc., can solve the problems of poor cylinder speed and stroke, time-consuming and labor-intensive operation, and low efficiency. Improve rigidity requirements, realize fine-tuning stroke, and increase the effect of tool setting function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

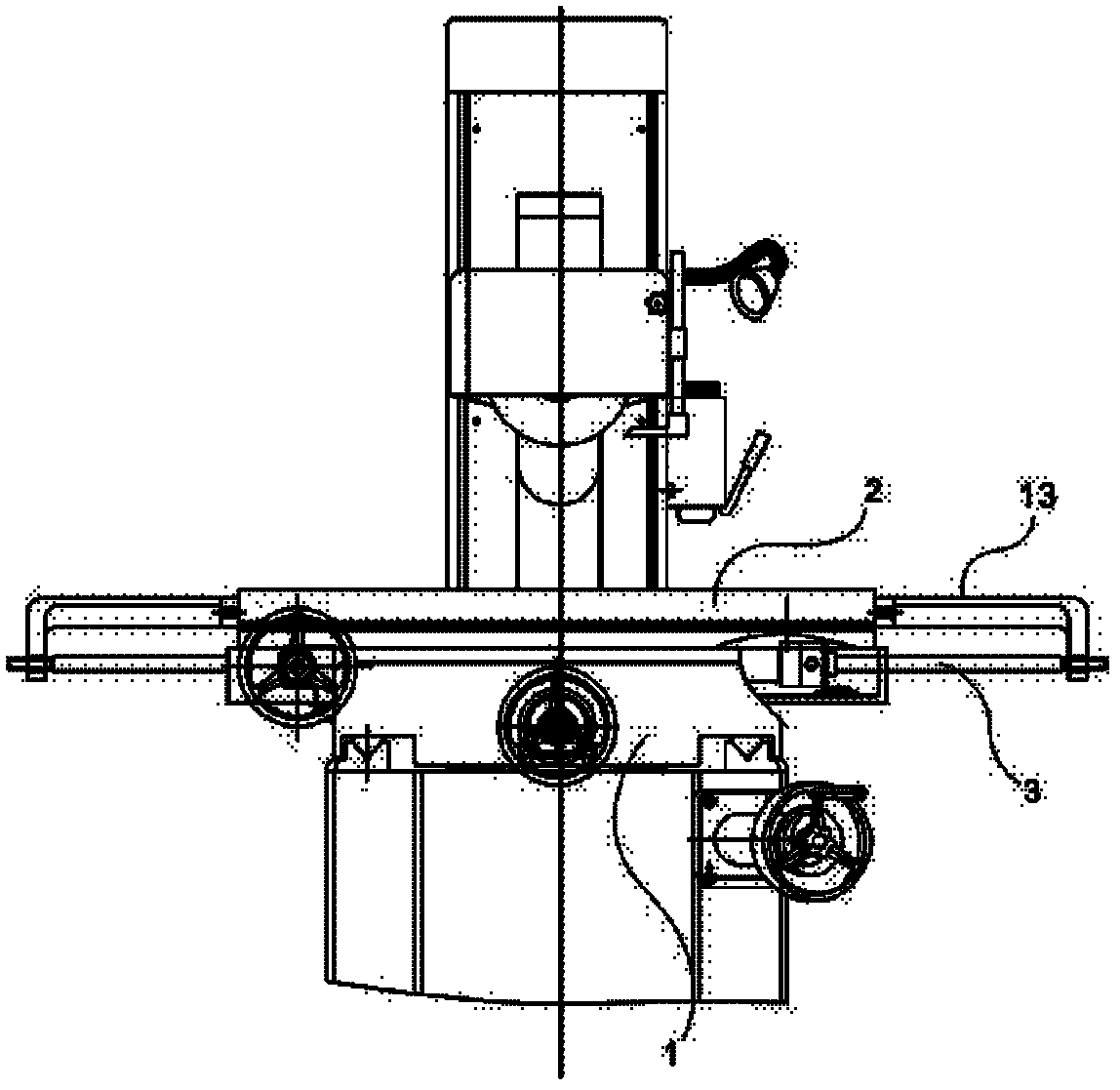

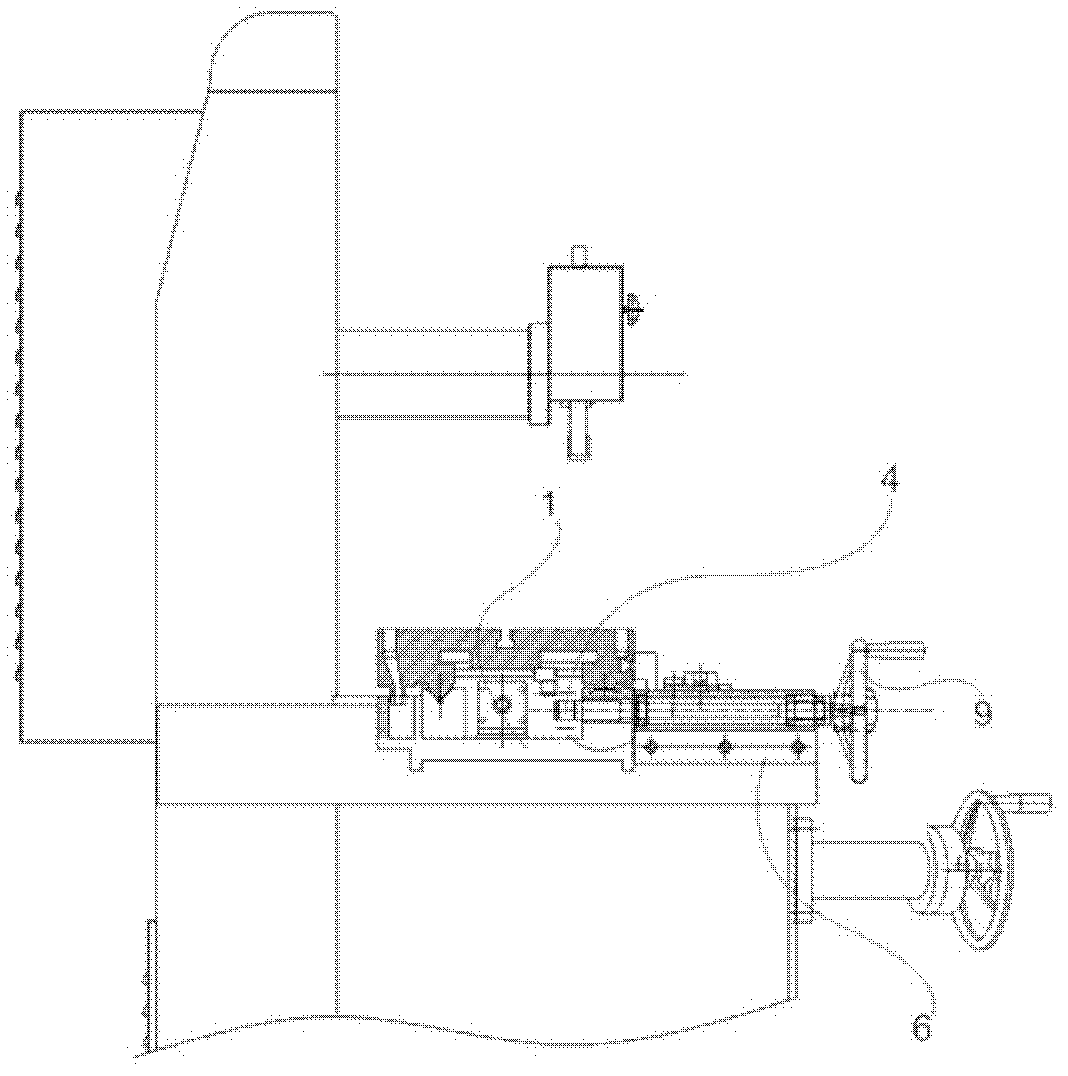

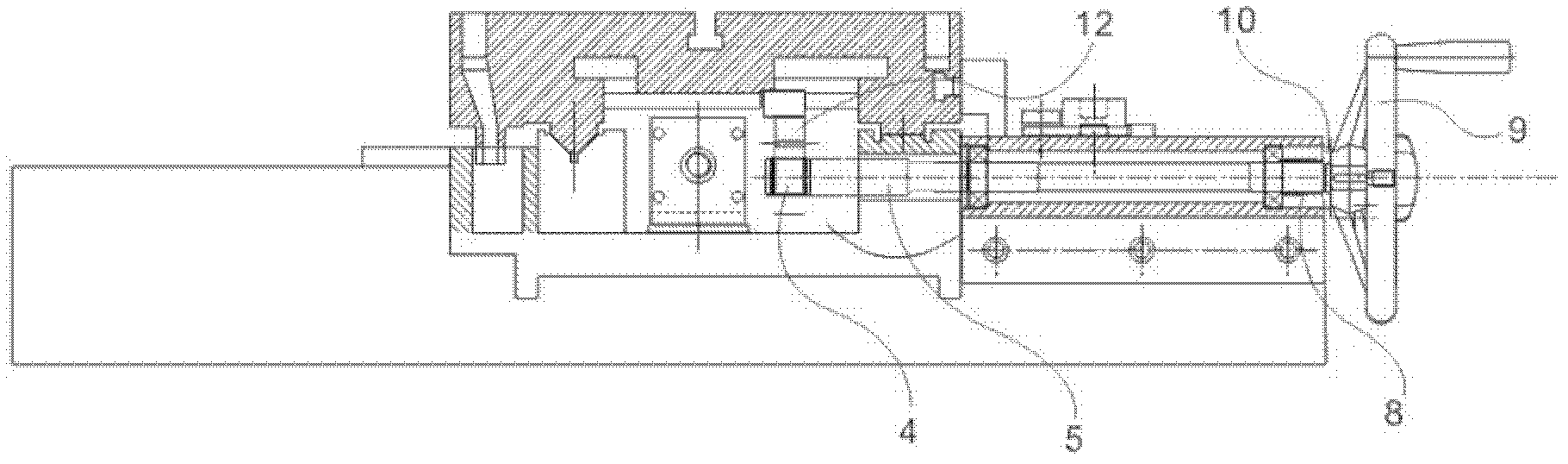

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings. Such as Figure 1-4 As shown in the figure, the grinder carriage 1, the hydraulic table 2, the oil cylinder 3, the fine-tuning gear 4, the transmission shaft 5, the bearing seat 6, the bearing 7, the elastic component 8, the hand-held rotation adjustment component 9, the elastic component Back-up ring 10, hydraulic valve speed regulation and start-stop handle 11, micro-movement rack 12, workbench oil cylinder connection pendant 13.

[0022] see Figure 1-4 As shown, the hydraulic transmission surface grinder proposed by the present invention includes a grinder carriage 1, a hydraulic workbench 2 and a manual adjustment device (not marked). The manual adjustment device includes a micro-movement rack 12 installed on the hydraulic workbench 2 and a mechanical drive device (not marked) installed on the grinding machine carriage 1 . The mechanical driving device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com