Double-fluid-ring drive omnibearing spherical robot

A spherical robot and two-fluid technology, applied in the field of electromechanical, can solve the problems of difficult engineering implementation, low practicability, complex structure, etc., and achieve the effects of easy processing, simple and reliable structure, and simplified driving device.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

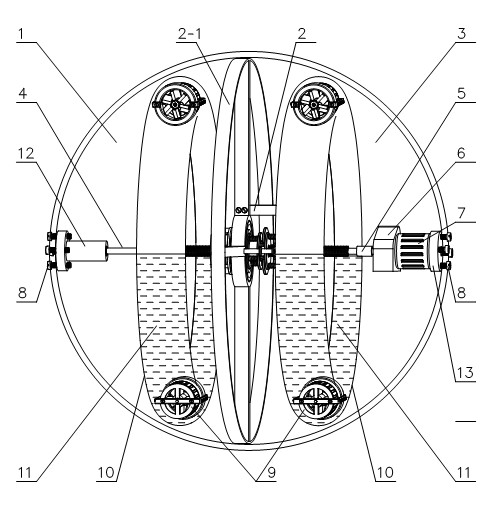

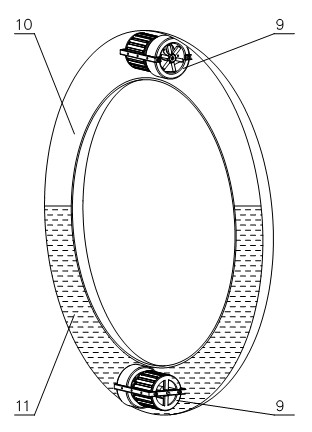

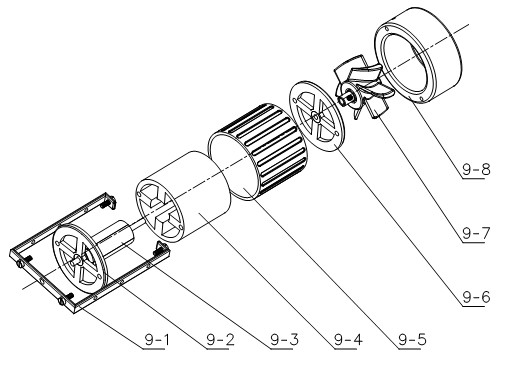

[0038] Such as figure 1 , 2 , 3, 4, and 5, an embodiment of the present invention is: a double-fluid ring-driven omnidirectional spherical robot device, which mainly includes a left hemispherical shell 1, a hemispherical clutch mechanism 2, a right hemispherical shell 3, a screw shaft 4, Coupling 5, reducer 6, motor 7, support seat fixing screw 8, axial flow component 9, annular sealed container 10, fluid 11, left support seat 12, right support seat 13, etc.; two annular seals The container 10 is fixedly connected inside the left hemispherical shell 1 and the right hemispherical shell 3 respectively. The annulus of the annular sealed container is coaxial with the spherical surface of the spherical shell on the screw shaft. The container contains fluid (usually liquid), and the volume of the fluid is the volume of the container. 1 / 2 (slightly greater than 1 / 2), two axial flow devices 9 are symmetrically installed inside each annular sealed container, and the axial flow device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com