Installation and removal crane for mining devices

A kind of equipment and mining technology, which is applied in the field of mining equipment removal cranes, can solve the problems of heavy physical installation process, high labor intensity of workers, poor interchangeability, etc., and achieve easy installation and maintenance, reduce labor intensity and work efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

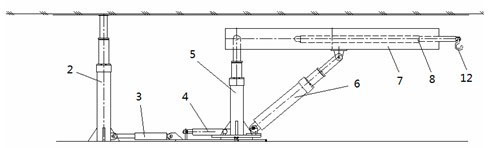

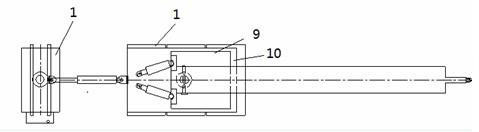

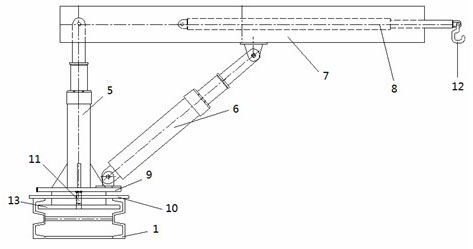

[0017] The specific implementation manners of the present invention will be described below in conjunction with the accompanying drawings. The mining equipment safety crane adopts a combined structure, which includes four parts: supporting part, rotating part, lifting part and pushing part. Wherein, the support part includes the guide block 13 that is installed in the chute 1, the guide block 13 is fixedly connected on the base fixed part 10, the base fixed part 10 top is the base rotating part 9, the base rotating part 9 can rotate The shaft 11 rotates as the center, and the supporting column 5 is fixedly installed on the base rotating part 9, and the diagonal brace column 6 is also hinged on the base rotating part 9, and the other end of the diagonal brace column 6 is hinged on the lifting arm 7.

[0018] The rotating part includes a rotating jack 4, and the number of rotating jacks 4 is two. One end of the rotating jack 4 is hinged on the base fixed part 10, and the other e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com