Moving bed bio-film reactor

A moving bed biofilm and reactor technology, applied in sustainable biological treatment, aerobic process treatment and other directions, can solve the problems of easy loss of fillers, easy accumulation of fillers at the water outlet, uneven distribution of fillers, etc., to ensure frequent flushing , Prevent accumulation, improve the effect of treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

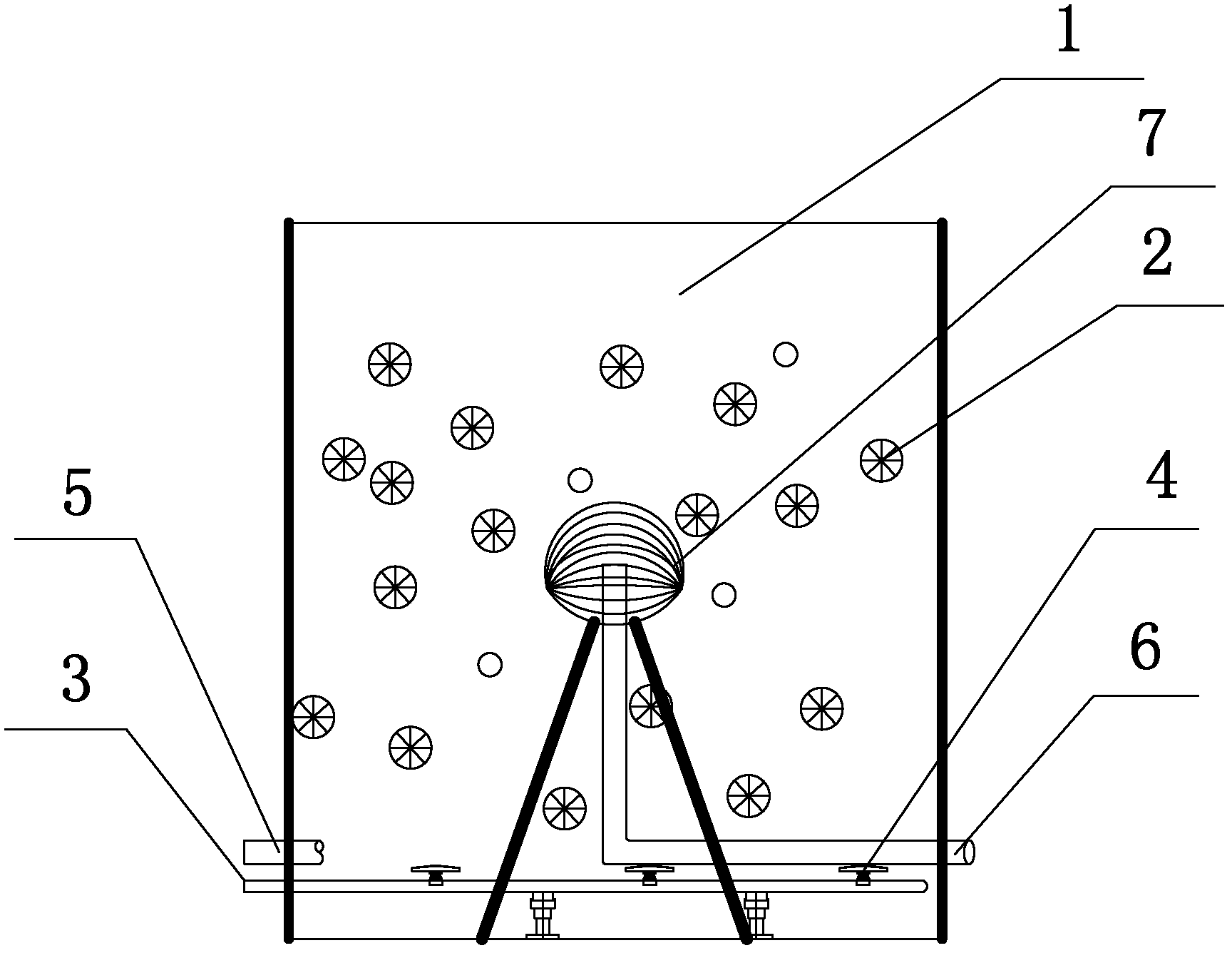

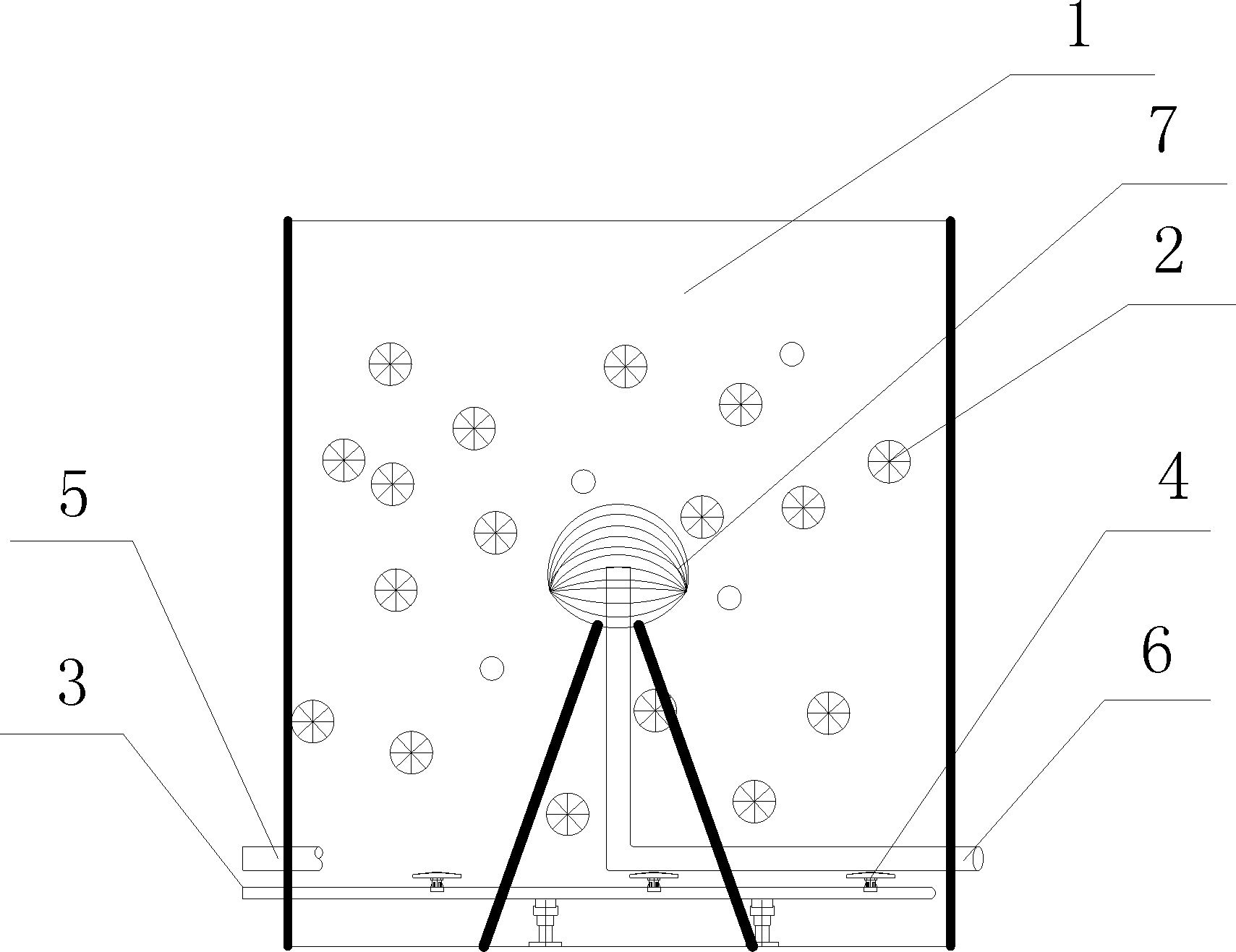

[0010] As shown in the accompanying drawings, a moving bed biofilm reactor provided by the present invention includes a reactor main body 1 filled with filler 2, and an aeration tube 3 is provided at the bottom of the reactor main body 1 for aeration. The pipe 3 is equipped with an aeration head 4; the side wall of the reactor main body 1 is equipped with a water inlet 5 and a water outlet 6, and the water inlet 5 and the water outlet 6 are located above the aeration pipe 3; the reactor main body 1 is also equipped with a water outlet screen Net 7, the screen 7 is connected to the water outlet 6 through a water pipe, the outlet screen 7 is fixed in the middle of the reactor main body 1 by a bracket, and the diameter of the outlet screen 7 is smaller than the diameter of the filler 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com