Polymethyl methacrylate composite coating and preparation method thereof

A technology of polymethyl methacrylate and composite coatings, applied in coatings and other directions, can solve problems affecting surface adhesion and gloss, complicated construction, etc., and achieve excellent color retention, improved construction efficiency, and high physical and mechanical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

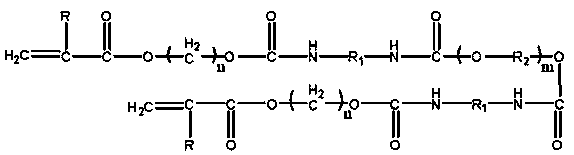

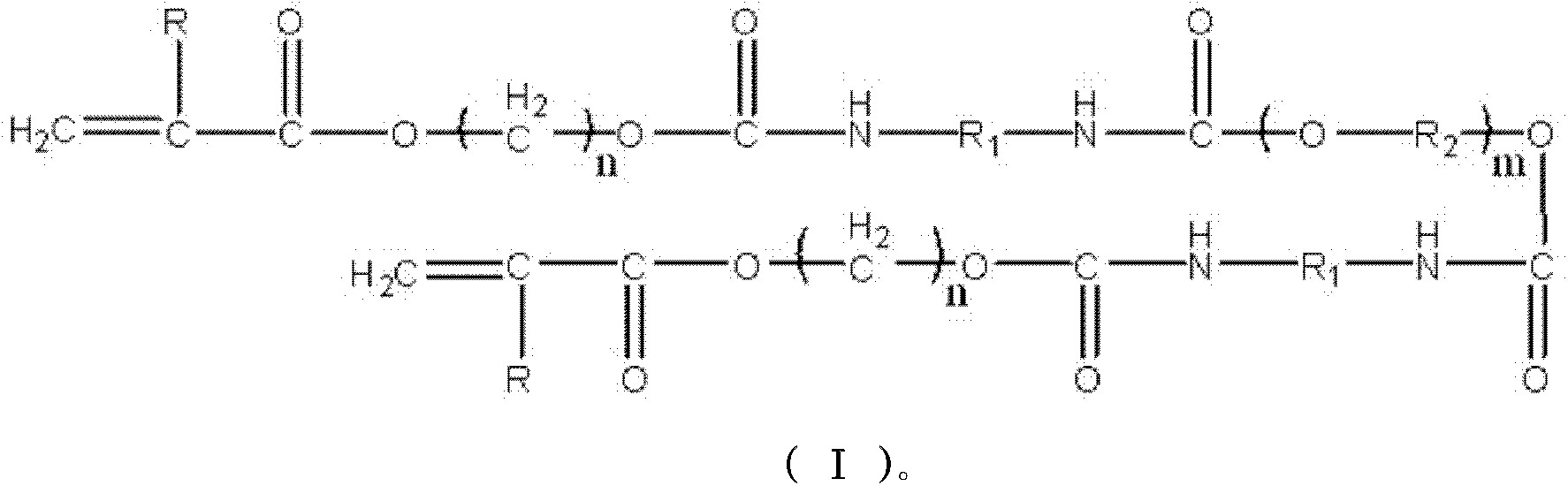

Method used

Image

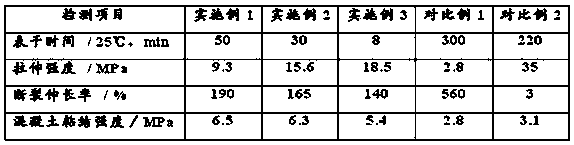

Examples

Embodiment 1

[0035] In a closed reaction kettle, blow dry nitrogen, add 15 parts of methyl methacrylate (MMA) and 1 part of benzoyl peroxide, stir until completely dissolved, then add 50 parts of flexible polyurethane unsaturated resin (molecular weight is about 8000 ), 2 parts of diallyl phthalate, 0.5 parts of p-toluenesulfonyl isocyanate, 1 part of diphenylbenzofuran and 30 parts of titanium dioxide (1250 mesh) were stirred and dispersed evenly, and finally 0.5 parts of reducing agent were added Capsules, mixed evenly, discharged under the protection of nitrogen, sealed and packaged to obtain the polymethyl methacrylate composite coating of this embodiment.

[0036] The reducing agent in the reducing agent capsule in this embodiment is N,N-dimethyl-p-toluidine.

Embodiment 2

[0038] In a closed reactor, blow dry nitrogen, add 30 parts of methyl methacrylate (MMA) and 3 parts of benzoyl peroxide, stir until completely dissolved, then add 40 parts of flexible polyurethane unsaturated resin (molecular weight is about 6000 ), 4 parts of dienyl phthalate, 1 part of p-toluenesulfonyl isocyanate, 1 part of triphenylphosphine and 20 parts of titanium dioxide (1250 mesh) were stirred and dispersed evenly, and finally 1 part of reducing agent capsule was added, Mix evenly, discharge and seal the package under nitrogen protection to obtain the polymethyl methacrylate composite coating of this embodiment.

[0039] The reducing agent in the reducing agent capsule in this embodiment is N,N-dimethyl-p-toluidine.

Embodiment 3

[0041] In a closed reactor, blow dry nitrogen, add 35 parts of methyl methacrylate (MMA) and 8 parts of benzoyl peroxide, stir until completely dissolved, then add 30 parts of flexible polyurethane unsaturated resin (molecular weight is about 4000 ), 2 parts of diallyl phthalate, 0.5 parts of p-toluenesulfonyl isocyanate, 1 part of diphenylbenzofuran and 23 parts of titanium dioxide (2500 mesh) were stirred and dispersed evenly, and finally 0.5 parts of reducing agent were added Capsules, mixed evenly, discharged under the protection of nitrogen, sealed and packaged to obtain the polymethyl methacrylate composite coating of this embodiment.

[0042] The reducing agent in the reducing agent capsule in this embodiment is N,N-dimethyl-p-toluidine.

[0043] In the above examples, the methyl methacrylate used is an industrial-grade raw material, and the viscosity of the monomer is low. When the composite coating is composed of polyurethane resin, the viscosity of the entire c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com