Imidazolium ionic liquid flame retardant containing cage phosphate structure and preparation method thereof

A technology of imidazole ionic liquid and caged phosphate, which is applied in chemical instruments and methods, compounds of Group 5/15 elements of the periodic table, organic chemistry, etc., can solve the problems of unsatisfactory effect when used alone and achieve good application prospects , Reduce the negative impact, the effect of simple process operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] 1) In N 2 Under protection, add 0.5mol PEPA and 0.5mol acid binding agent triethylamine to dichloromethane successively, stir for 10min at room temperature and 25℃, and then add 0.5mol methylsulfonyl chloride dropwise. The dropping time is controlled for 1.5h. After the addition, the reaction was carried out at 25°C for 6 hours. After the reaction, the dichloromethane was distilled off, and the intermediate was obtained after washing and drying. The yield was 85%. The structure is as follows:

[0040]

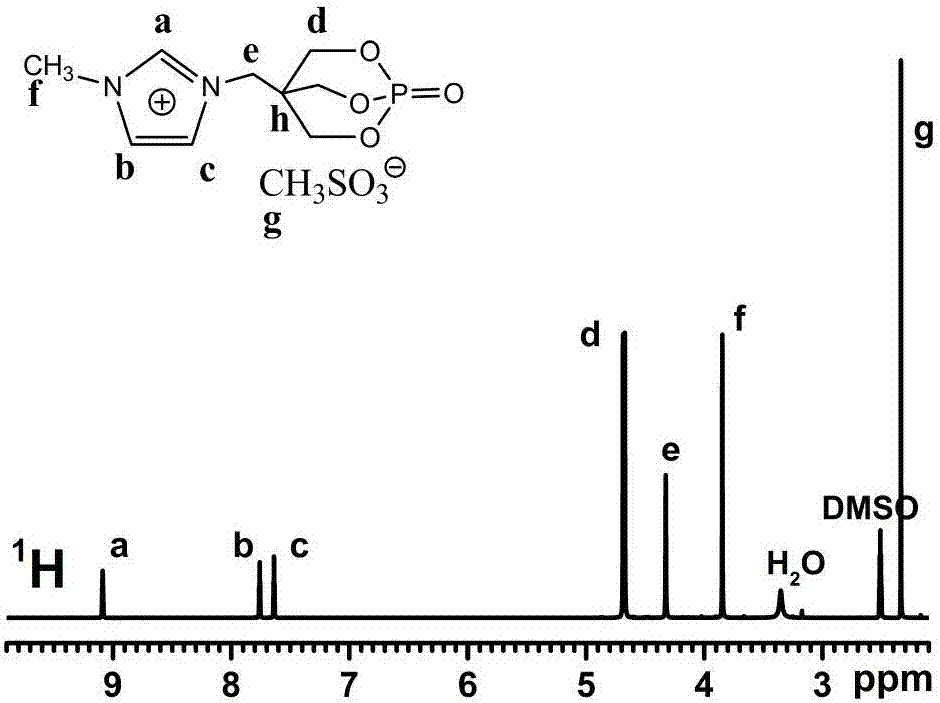

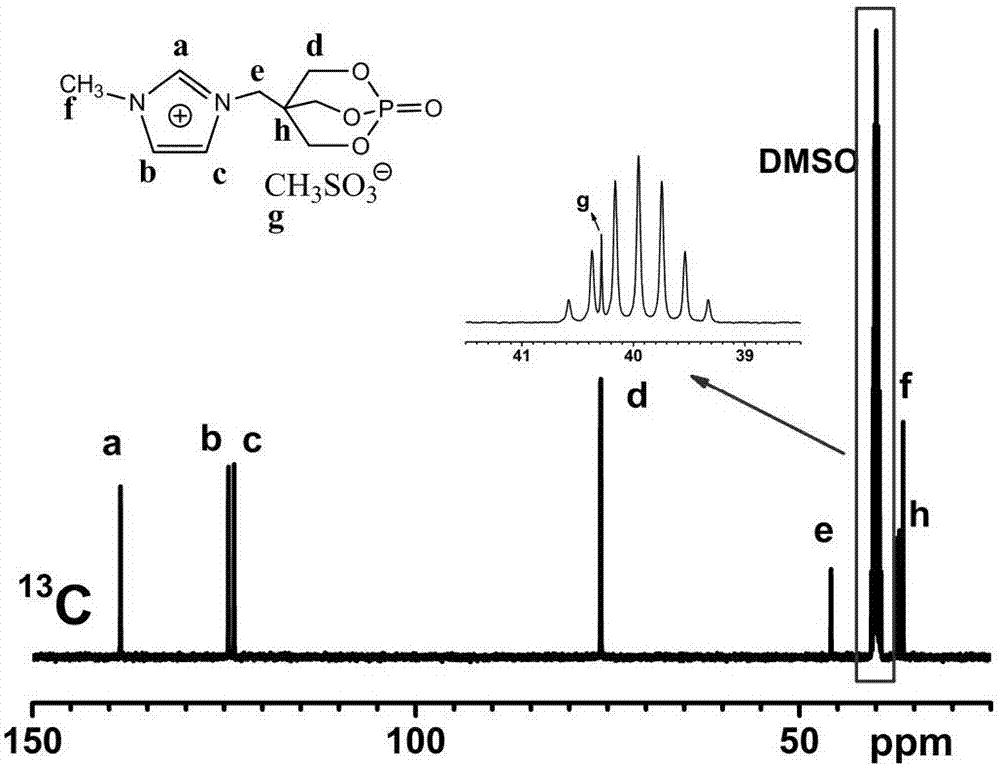

[0041] 2) Dissolve the obtained 0.5mol intermediate in the solvent 1-methylimidazole, then add 0.5mol 1-methylimidazole, and 2 Under protection, the temperature was raised to 85℃ and the reaction was stirred for 48h. The solvent 1-methylimidazole was distilled off, the residue was washed 3-4 times with acetone, and dried to obtain an imidazole ionic liquid flame retardant with methanesulfonate anion. The yield was 76%. Its structural formula is as follows:

[0042]

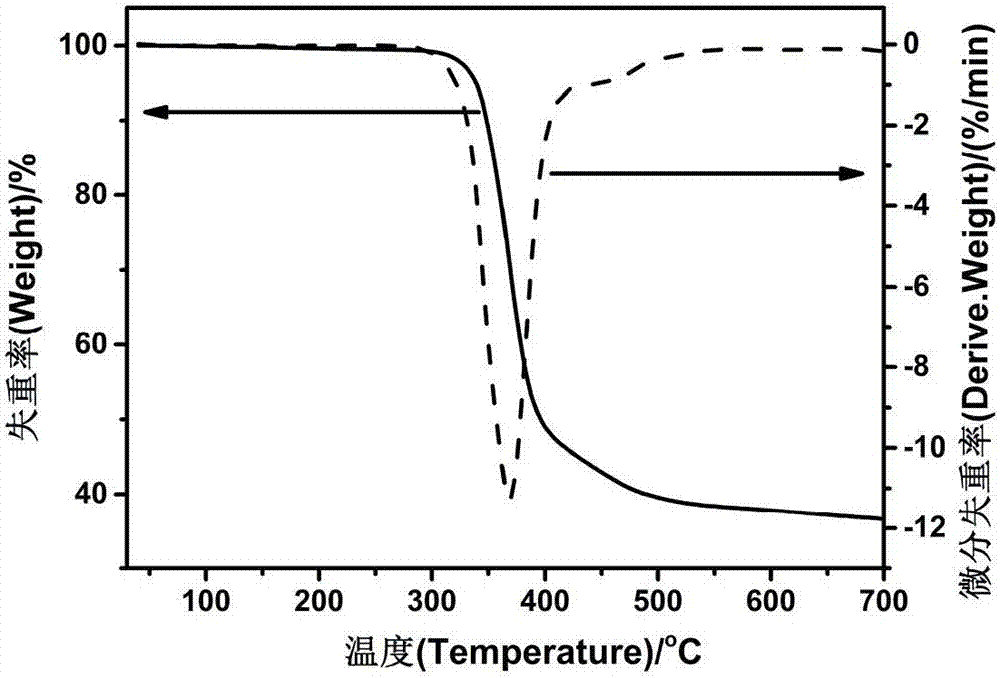

[0043] ...

Embodiment 2

[0045] 1) In N 2 Under the protection, add 0.5mol PEPA and 0.6mol acid binding agent triethylamine to acetone successively, stir at room temperature 25℃ for 20min, then add 0.75mol p-toluenesulfonyl chloride dropwise, the dropping time is controlled for 3h, after the dropping The reaction was carried out at 25°C for 8 hours. After the reaction, the acetone was distilled off, and the intermediate was obtained after washing and drying. The yield was 88%. The structure is as follows:

[0046]

[0047] 2) Dissolve 0.5 mol of the obtained intermediate in 1-methylimidazole, then add 0.6 mol of 1-methylimidazole, and add in N 2 Under protection, the temperature was raised to 83℃ and the reaction was stirred for 58 hours. The solvent 1-methylimidazole was distilled off. The residue was washed 3-4 times with acetone and dried to obtain an imidazole ionic liquid flame retardant with p-toluenesulfonate anion. The yield was 72%. Its structural formula is as follows:

[0048]

[0049] 3) The f...

Embodiment 3

[0051] 1) In N 2 Under protection, add 0.5mol PEPA and 0.5mol acid binding agent triethylamine to dichloromethane successively, stir at room temperature 25℃ for 10min, then add 0.52mol 1-butylsulfonyl chloride dropwise, and the dropping time is controlled for 1.5h. After the dropwise addition, the reaction was carried out at 26°C for 6 hours. After the reaction, the dichloromethane was distilled off, and the white intermediate was obtained after washing and drying. The yield was 78%, and the structure was as follows:

[0052]

[0053] 2) Dissolve the obtained 0.5mol intermediate in the solvent 1-methylimidazole, then add 0.5mol 1-methylimidazole, and 2 Under protection, the temperature was raised to 80℃ and the reaction was stirred for 50h. The solvent 1-methylimidazole was distilled off. The residue was washed 3-4 times with acetone and dried to obtain an imidazole ionic liquid flame retardant with butyl sulfonate anion. The yield was 75%. Its structural formula is as follows:

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com