Linen blend manufacturing process

A manufacturing process, flax technology, applied in the field of flax blending manufacturing process, can solve the problems of increasing the cost of production raw materials, difficult to produce high-quality products, etc., to avoid broken strands or accidental drafting, reduce differences, and achieve uniform weight Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The manufacturing process of 24 public count linen yarn blending is as follows:

[0036] Selection of flax long hemp fiber raw material → combing machine → combing hemp → sliver frame → 0 draw frame → 1 draw frame → 2 draw frame → 3 draw frame → final draw frame → roving machine→scouring and bleaching pot→spinning frame→dryer→automatic winder→finished product packaging, its innovation lies in:

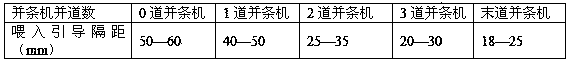

[0037] a. When the flax long hemp fiber raw material carding and manufacturing process passes through two drawing frame processes, the combed flax short hemp fiber slivers made by carding and finishing the flax short hemp fiber raw material production line are added to the flax long hemp spinning process , when adding, select the middle front position of each feeding hemp sliver to feed, and at the same time, the feeding guide sheet spacing is set as 35mm; the flax short hemp fiber raw material production line is the flax short hemp fiber raw material→combined carding machine→ ...

Embodiment 2

[0070] The different parts in the manufacturing process of the blended spinning of 28 common count flax yarns and the manufacturing process of embodiment 1 are as follows

[0071] In drawing process:

[0072] Number of channels Draft multiple Bar weight (g) Combined number Feeding guide piece width (mm) Remark Second draw frame 10.627 13.5 8 32 Add short hemp strips after this process machine Three draw frames 10.284 11.22 8 28 Four draw frame 9.159 4.9 4 22 Roving 9.94 0.5 1 18

[0073] The specific parameters of the pre-light bleaching process described in the boiling and bleaching process are: the pre-light bleaching solution contains sulfuric acid (H 2 SO 4 ) 2.7 g / L, sodium chlorite (N a CLOs 2 ) 1.7 g / L, sodium nitrate (NaNO 3 ) 1 g / L and penetrant (JFC) 1.3 g / L aqueous solution; keep warm for 50 minutes at 45°C;

[0074] Washing: hot water washing, cold water washing, overflow washing;

[007...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com