Integrated construction equipment for binding and lifting continuous beam steel reinforcement framework and construction method

A steel frame and beam reinforcement technology, which is applied to the integrated construction equipment and construction field of continuous beam steel frame binding and hoisting, can solve the problems of narrow operating space for hanging baskets, high construction costs, and inability to work in parallel, so as to save time for steel bar binding, The effect of eliminating safety hazards and shortening construction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

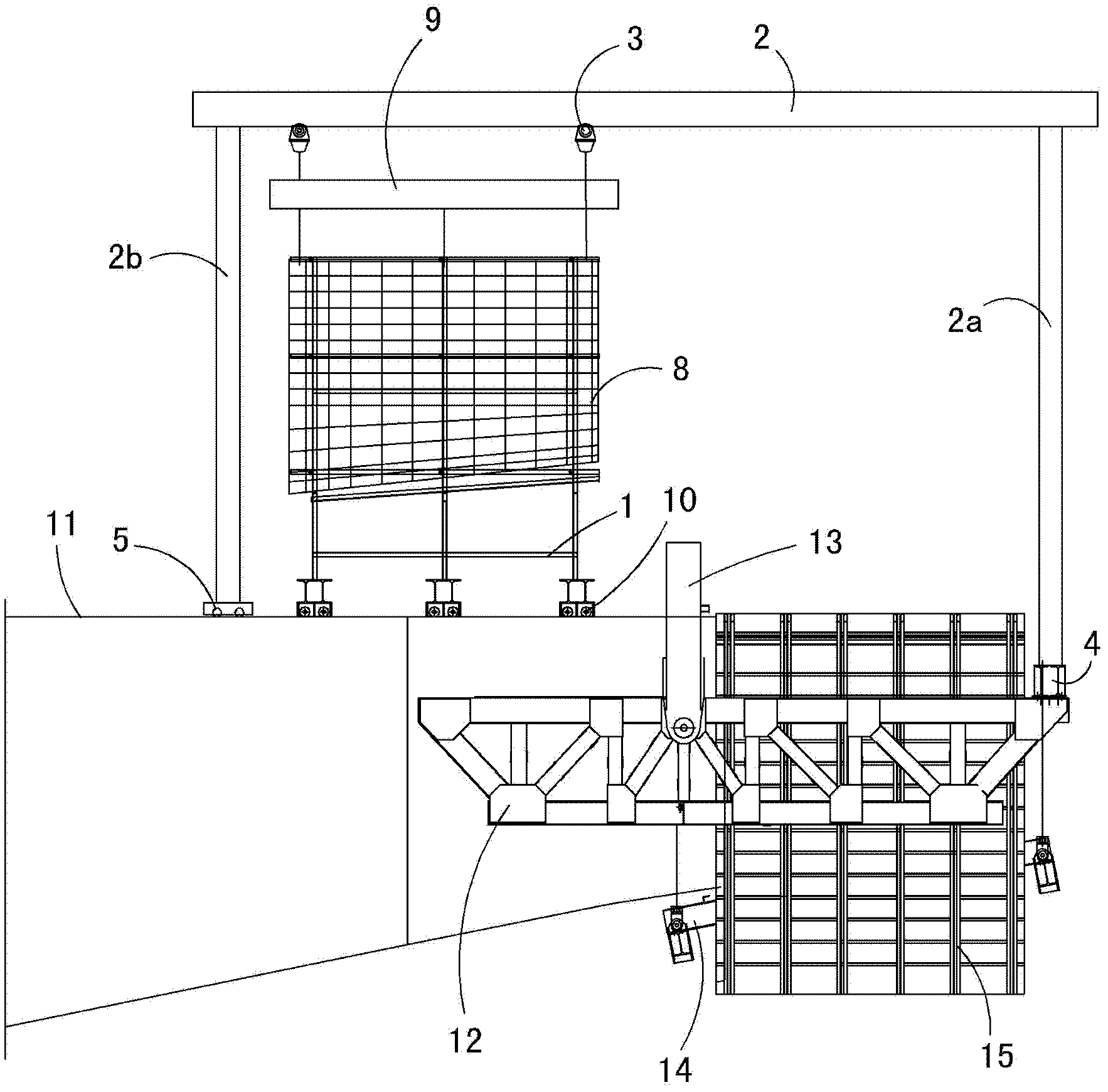

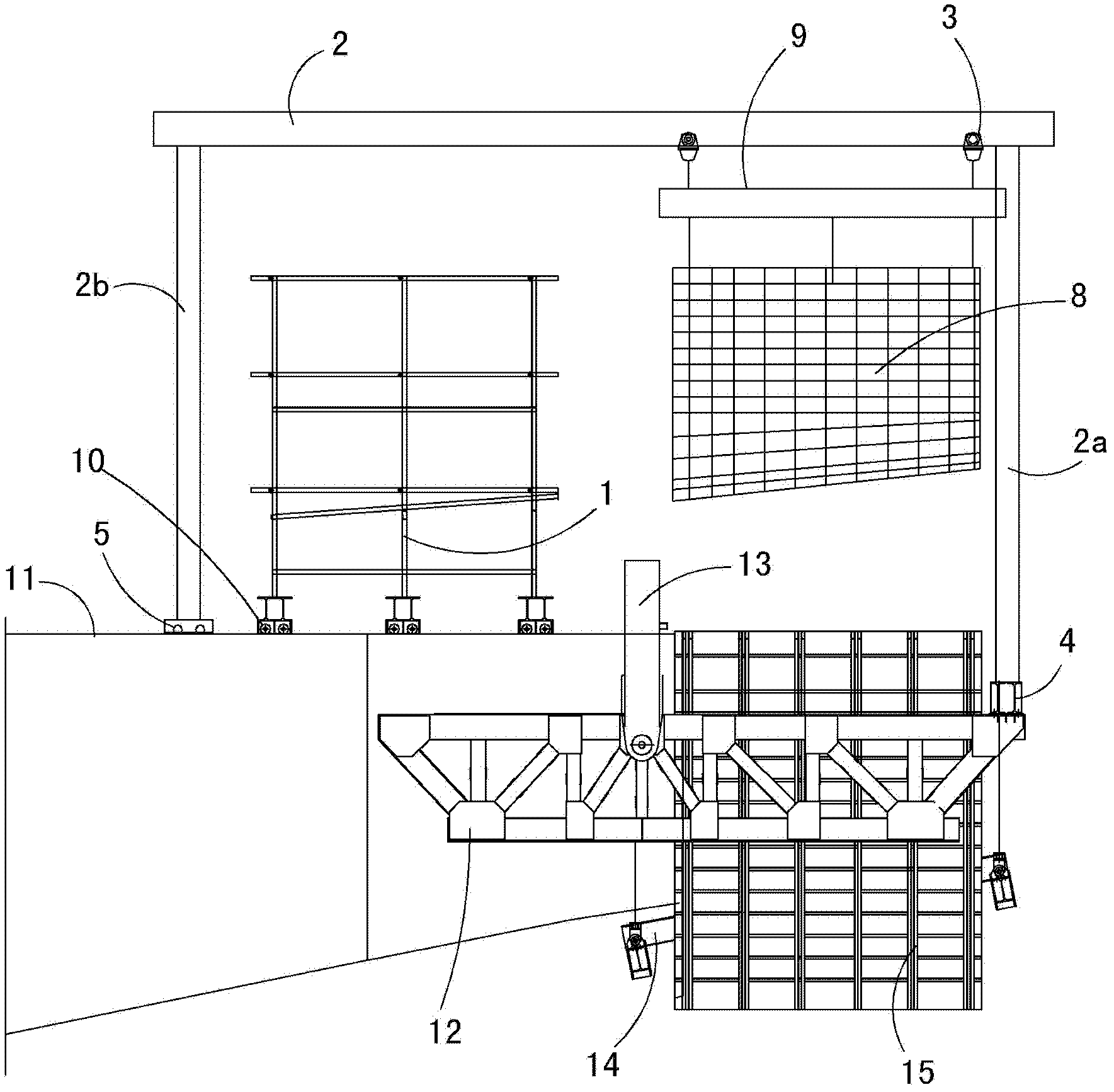

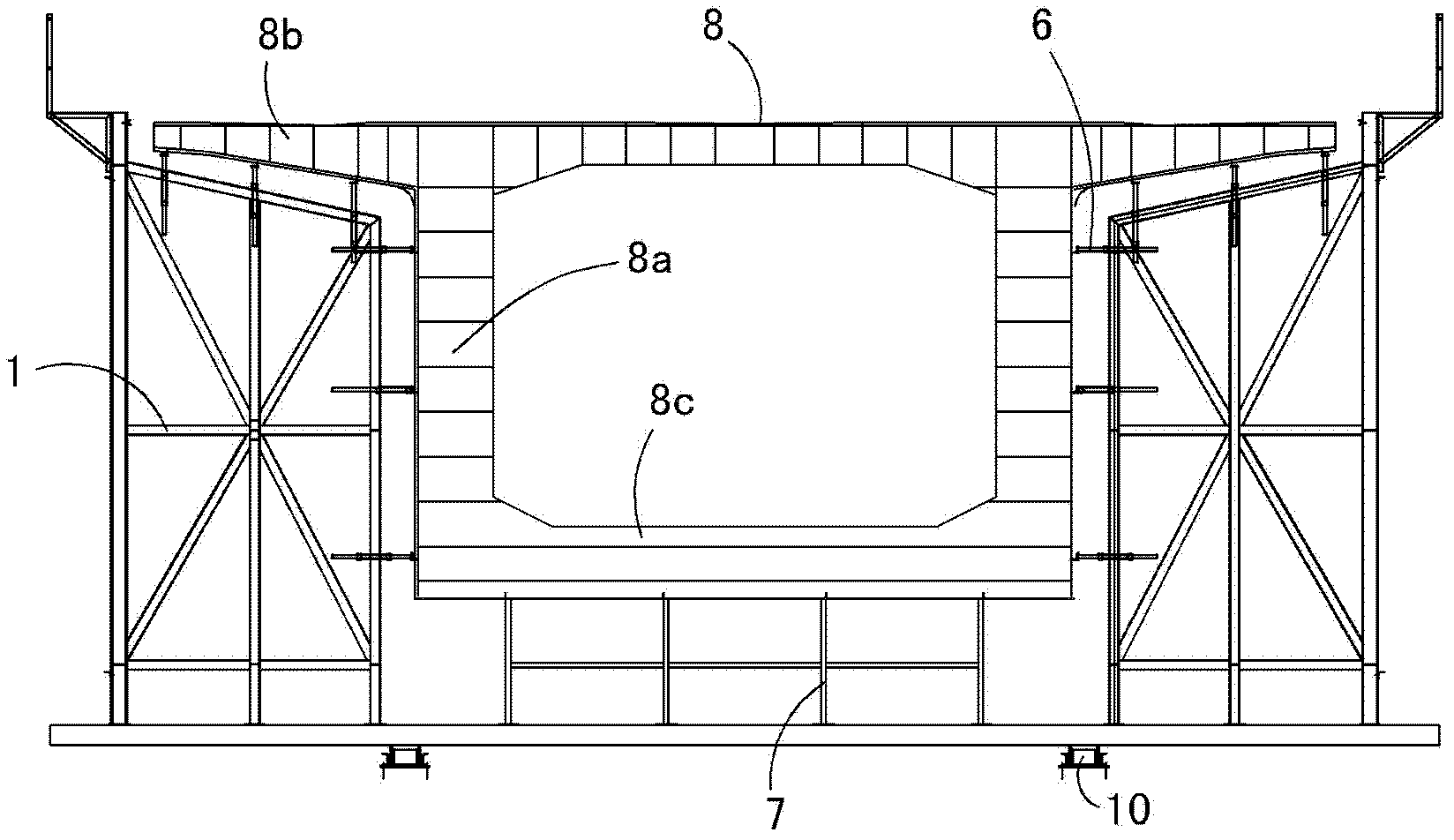

[0032] see figure 1 and figure 2 , this embodiment is aimed at the under-supported hanging basket in the bridge construction disclosed in the utility model with the publication number of 201972099U. Composed together with the side form 15, the main truss 12, the front upper beam 4 and the rear upper beam 13 play a supporting role in the concrete pouring process, and the bottom form 14 and the side form 15 are concrete pouring formwork.

[0033] In specific implementation, such as figure 1 and figure 2 , on the poured beam surface 11, a steel bar binding mold 1 for binding the steel bar skeleton 8 is arranged; a truss-type sliding spreader 2 is arranged longitudinally above the steel-bar binding mold 1, and the front end of the truss-type sliding spreader 2 passes through the front end The bracket 2a is supported on the upper beam 4 in front of the hanging basket, and the tail end is supported on the poured beam surface 11 through the tail bracket 2b; the crane 3 is instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com