Extra-high-voltage electrical equipment shock-insulating supporting seat with adjustable rigidity and damping

A technology for electrical equipment and seismic isolation bearings, which is applied in the direction of earthquake resistance, building components, buildings, etc., can solve the problems that cannot be adjusted independently, does not have, and the isolation bearings cannot be directly used for equipment isolation, so as to achieve good bending resistance. effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

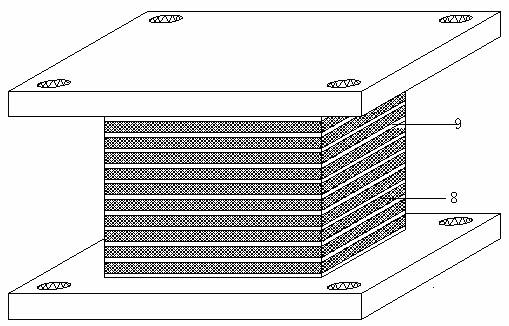

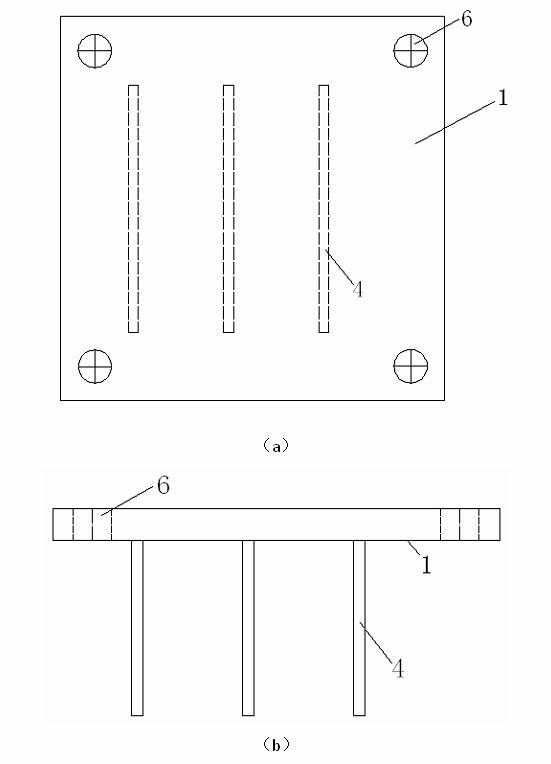

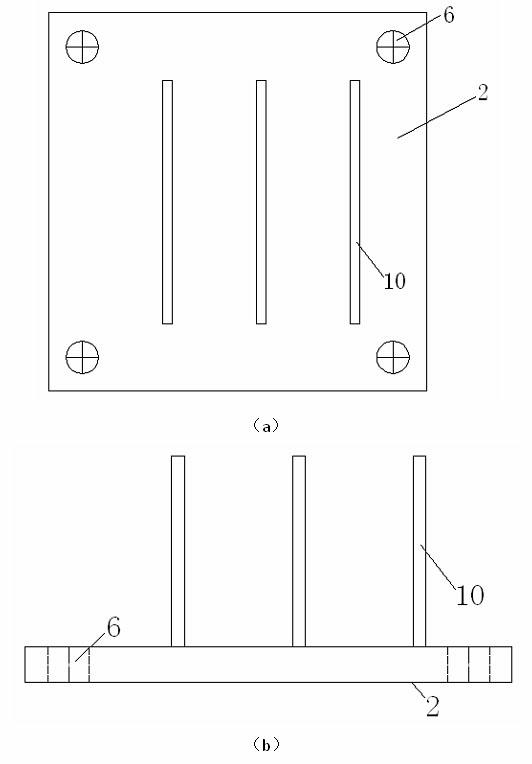

[0021] Embodiment 1: as figure 2 and image 3 As shown, the upper end plate 1 and the lower end plate 2 of the seismic isolation support are in a rectangular structure, and there are through bolt holes 6 on the four corners, which are used for anchoring with the lower bracket and upper equipment; the first steel plate teeth 4 are vertically Welded to the bottom of the upper end plate 1 to form an upper toothed steel device; the second steel plate teeth 10 are vertically welded to the top of the lower end plate 2 to form a lower toothed steel device. The first steel plate teeth 4, the second steel plate teeth 10 and the third steel plate teeth 11 are all rectangular structures with the same thickness and size, and the number and spacing of the steel plate teeth are determined according to the shock absorption requirements of the actual equipment. The size and thickness of the upper end plate 1, the lower end plate 2 and the middle plate 3 are also the same. like Figure 4 A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com