Load-bearing adjustable zero-stiffness electromagnetic vibration isolator and control method thereof

A zero-stiffness, vibration isolator technology, applied in the field of load-bearing adjustable zero-stiffness electromagnetic vibration isolators and its control, can solve the problems that the vibration isolation system deviates from the quasi-zero stiffness working state and cannot achieve the vibration isolation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

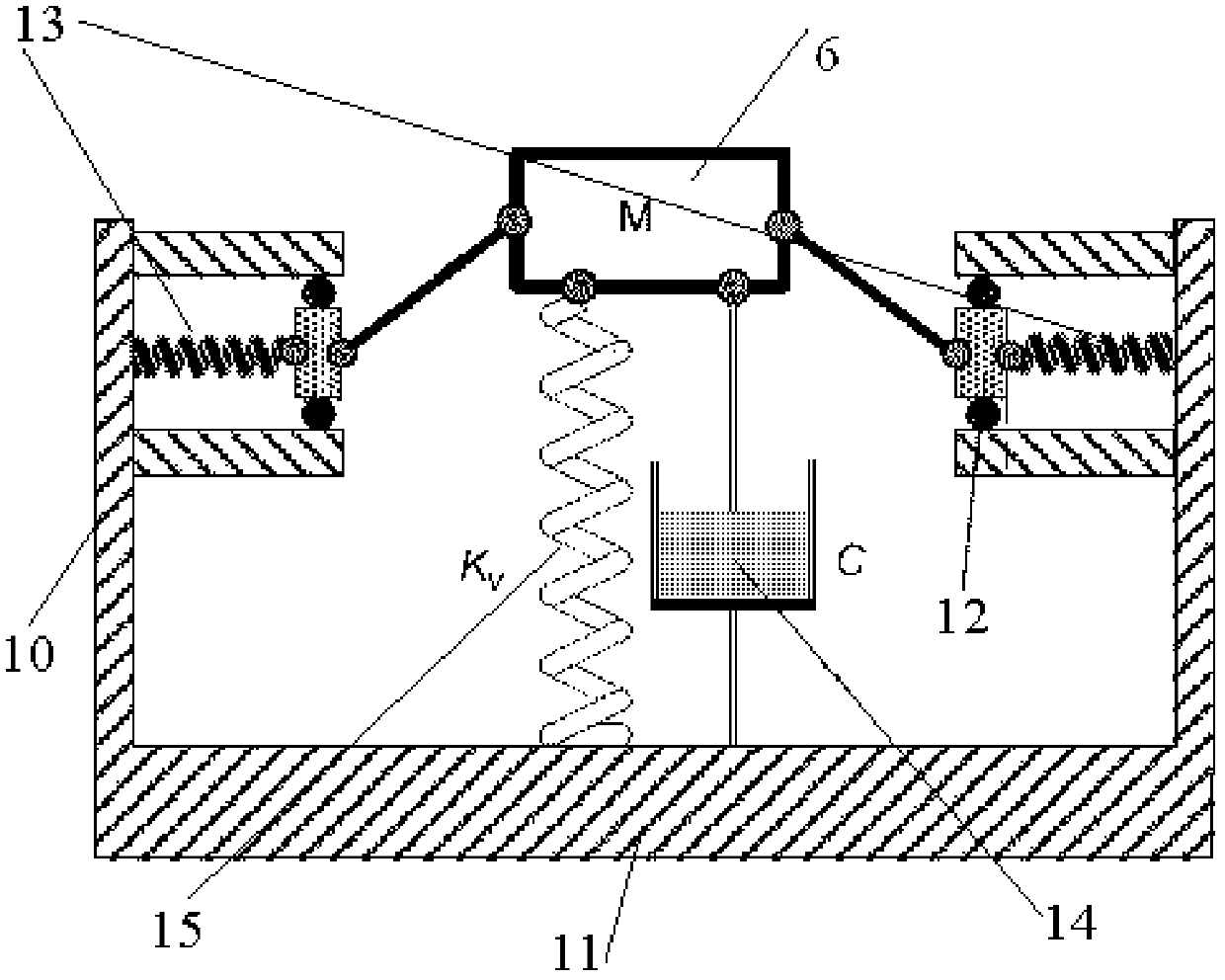

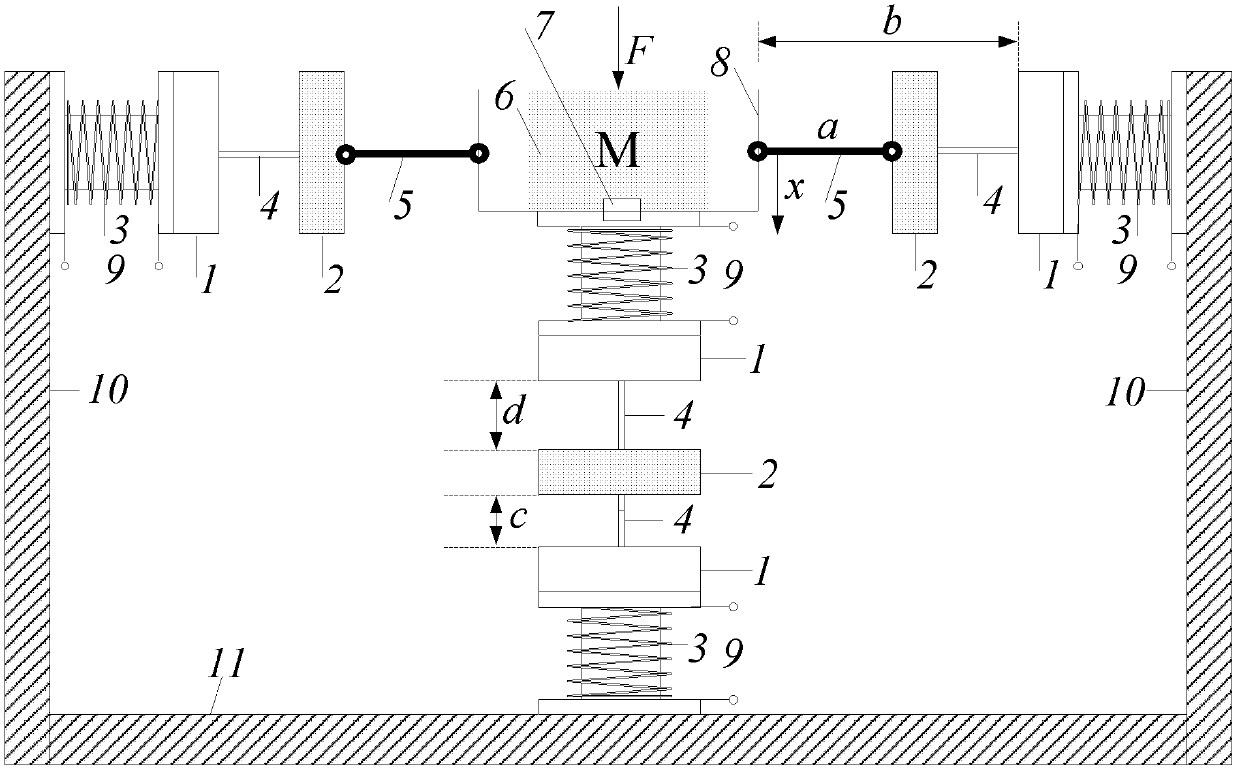

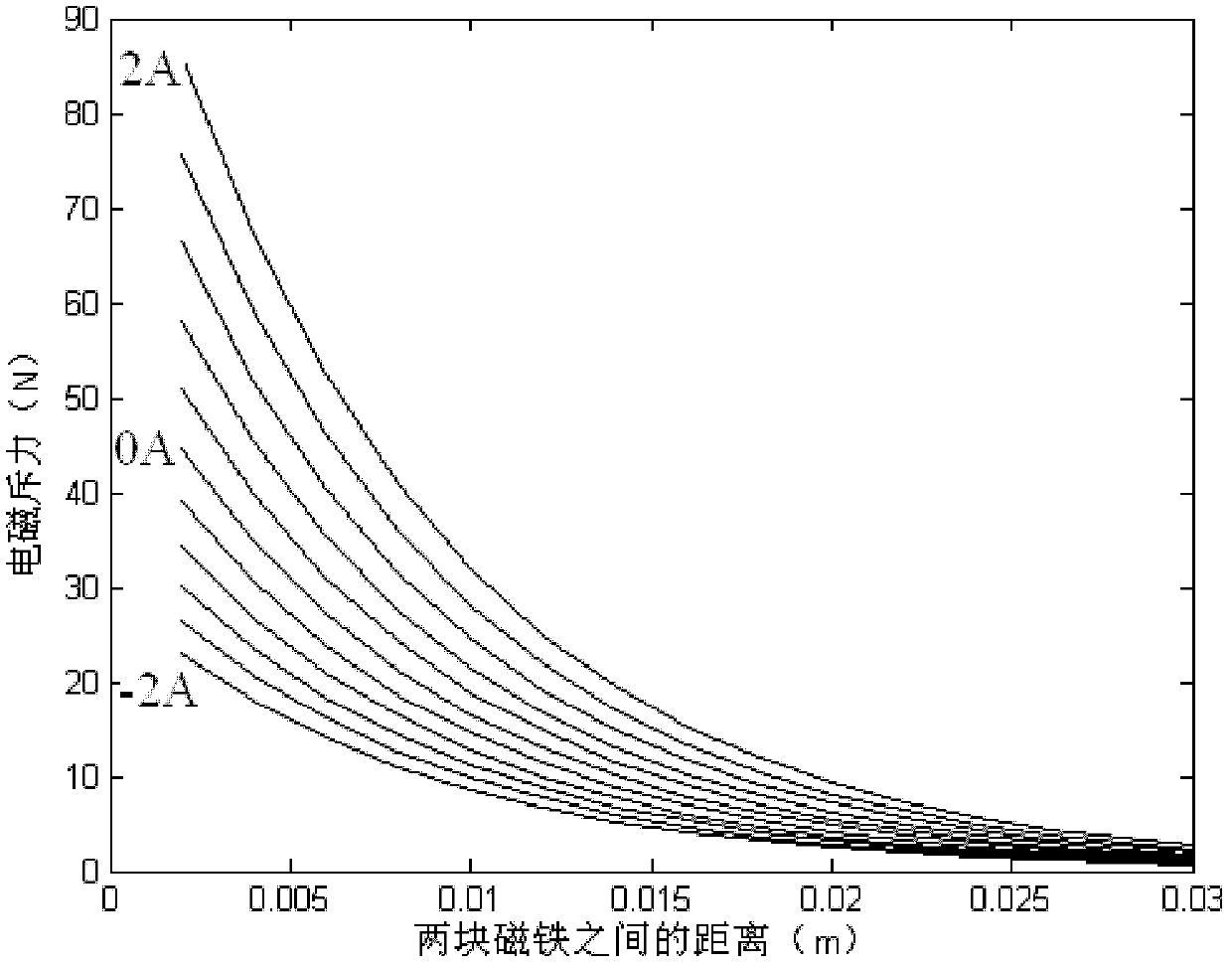

[0035] Such as figure 2 As shown, an embodiment of the present invention includes a vibration isolation device 6, a group of electromagnetic springs in the vertical direction, and two groups of electromagnetic springs in the horizontal direction. The outer frame 10 is installed on the left and right sides of the base 11, and the control circuit 9 is also included. The electromagnetic spring includes a set of electromagnets and two permanent magnets. The right side of the vibration isolation device 6 is connected to the first permanent magnet of the right horizontal electromagnetic spring through a connecting rod, and the first permanent magnet of the right horizontal electromagnetic spring is The magnet is connected with the second permanent magnet through the guide bar 4, and the second permanent magnet is connected with the electromagnet, and the electromagnet is fixed on the right outer frame 10; the electromagnetic spring in the vertical direction includes two groups of el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com