Bottom rubber interlining type joined V-belt

A sandwich-type, primer technology, applied in the direction of V-shaped belts, belts/chains/gears, mechanical equipment, etc., can solve the problems of short life, narrow temperature range, etc., achieve long service life, stable performance, and improve physical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

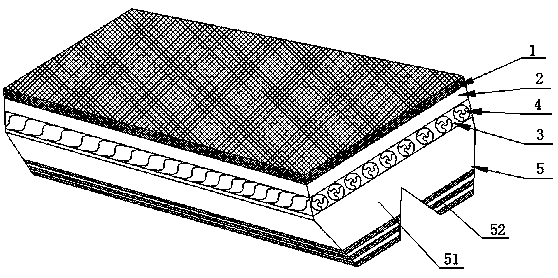

[0034] like figure 1 A combination of bottom rubber and cloth type V-belt is shown, and the group of bottom rubber and cloth type V-belts sequentially includes a top cloth layer 1, a stretch layer 2, an adhesive layer 3 and a compression layer 5 from the outside to the inside, The inner surface of the compression layer 5 is flat and has a V-shaped groove in the middle of the inner surface. A skeleton layer 4 is distributed in the adhesive layer 3. The constituent material of the skeleton layer 4 is polyester cord (Zhejiang Haizhimen Rubber & Plastic Co., Ltd. , polyester hard cord, specification 1100dtex), the thickness of the top fabric layer 1 is 0.5mm, the thickness of the stretch layer 2 is 2.0mm, the thickness of the skeleton layer 4 is 0.8mm, the thickness of the adhesive layer 3 is 1.0mm, and the thickness of the compression layer 5 is 6.0mm. The compression layer 5 is made up of the main rubber layer 51 on the outside and the bottom rubber layer 52 inside, the main ru...

Embodiment 2

[0043] A combination of bottom rubber and cloth type V-belt, the combined bottom rubber and cloth type V-belt sequentially includes a top cloth layer 1, a stretch layer 2, an adhesive layer 3 and a compression layer 5 from the outside to the inside, and the compression layer 5 The inner surface is flat and has a V-shaped groove in the middle of the inner surface. A skeleton layer 4 is distributed in the adhesive layer 3. The constituent material of the skeleton layer 4 is polyester cord (Zhejiang Haizhimen Rubber & Plastic Co., Ltd., polyester Hard cord, specification 1100dtex), the thickness of the top fabric layer 1 is 1.0mm, the thickness of the stretch layer 2 is 5.0mm, the thickness of the skeleton layer 4 is 1.5mm, the thickness of the adhesive layer is 2.0mm, and the thickness of the compression layer 5 is 15.0mm. The compression layer 5 is made up of the main rubber layer 51 on the outside and the bottom rubber layer 52 inside, the main rubber layer 51 is connected to t...

Embodiment 3

[0052] A combination of bottom rubber and cloth type V-belt, the combined bottom rubber and cloth type V-belt sequentially includes a top cloth layer 1, a stretch layer 2, an adhesive layer 3 and a compression layer 5 from the outside to the inside, and the compression layer 5 The inner surface is flat and has a V-shaped groove in the middle of the inner surface. A skeleton layer 4 is distributed in the adhesive layer 3. The constituent material of the skeleton layer 4 is polyester cord (Zhejiang Haizhimen Rubber & Plastic Co., Ltd., polyester Hard cord, specification 1100dtex), the thickness of the top fabric layer 1 is 0.8mm, the thickness of the stretch layer 2 is 3.0mm, the thickness of the skeleton layer 4 is 1mm, the thickness of the adhesive layer 3 is 1.5mm, and the thickness of the compression layer 5 is 10mm. The compression layer 5 is made up of the main rubber layer 51 on the outside and the bottom rubber layer 52 inside, the main rubber layer 51 is connected to the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com