Detection device for anisotropy of optical element

An optical element and anisotropy technology, which is applied in the field of optical element anisotropy detection device, can solve the problems of inability to accurately measure optical elements and inability to detect anisotropy of optical elements, so as to eliminate measurement blind spots, reduce mode competition, less demanding effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

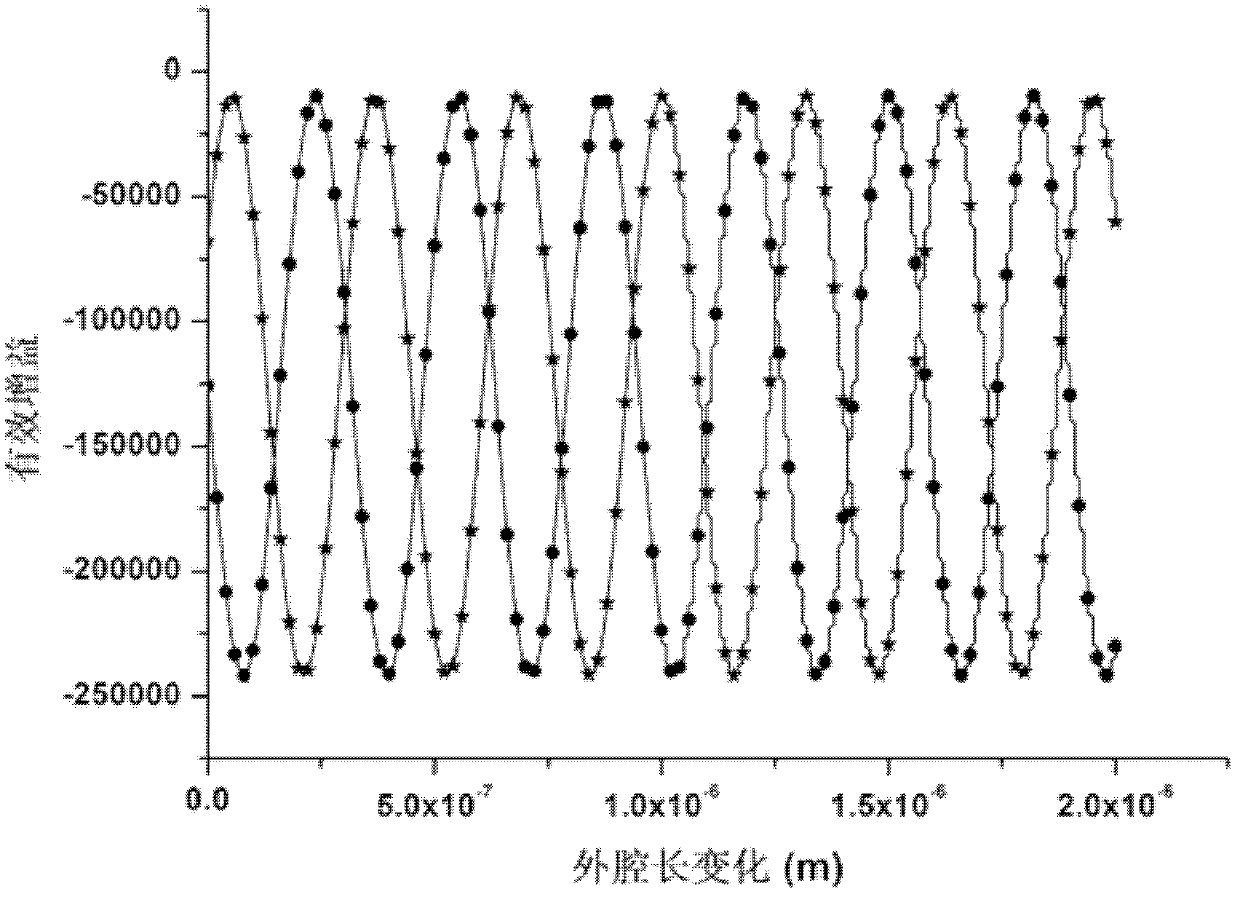

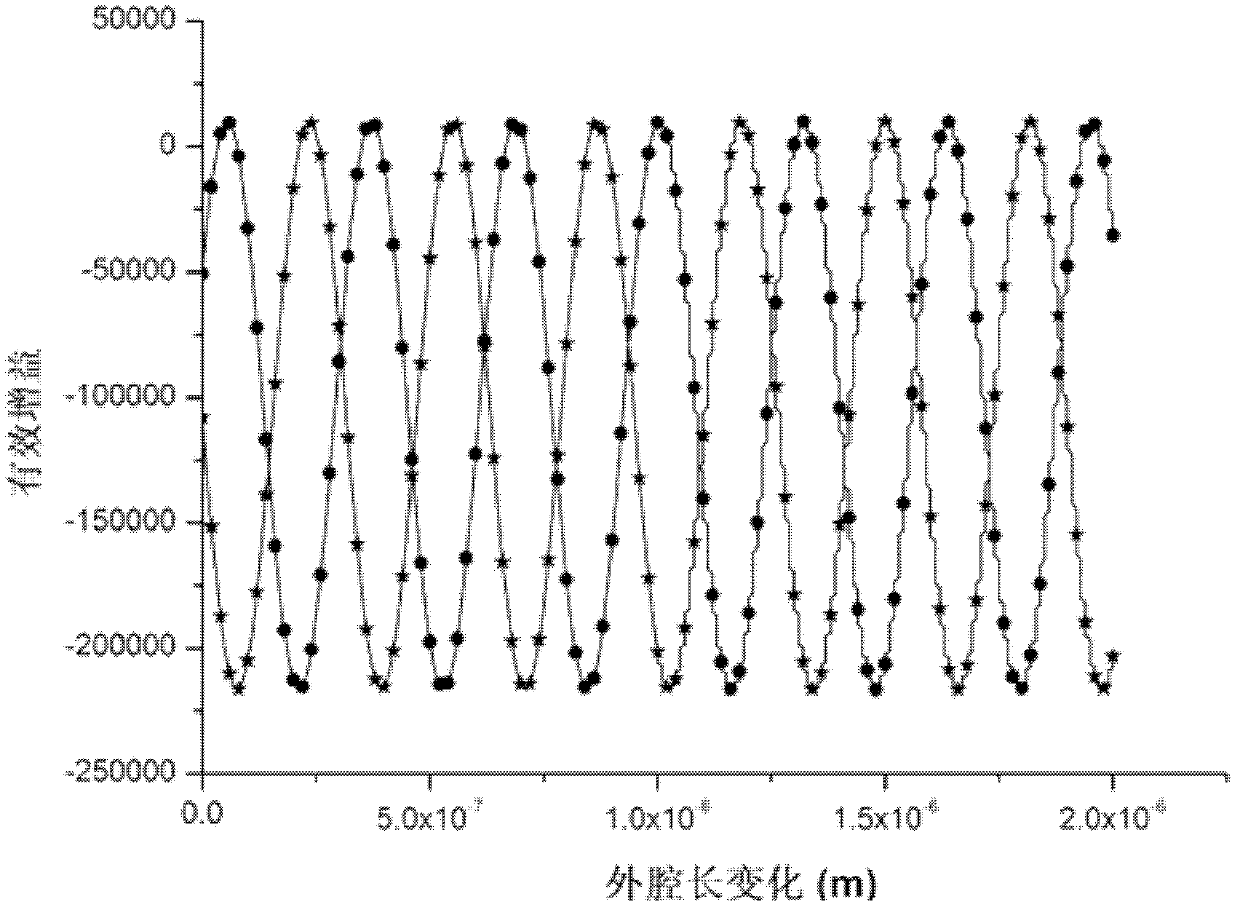

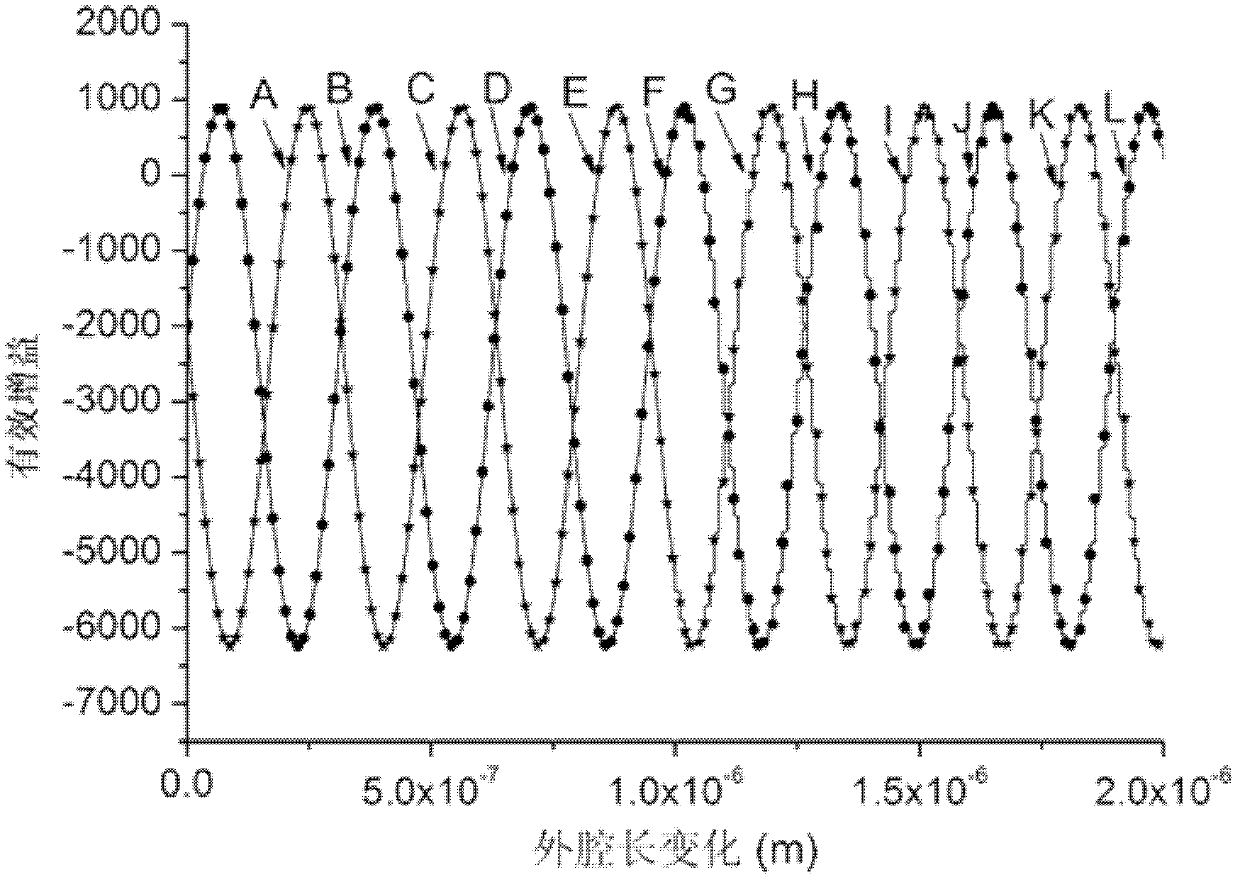

[0018] If an anisotropic optical element is placed in the laser resonator, the laser light emitted by the laser can be split into two beams of light with two eigenmode polarization directions perpendicular to each other. These two kinds of light are usually represented by o light and e light . In the semiclassical theory of lasers, whether the laser mode can oscillate depends on two conditions:

[0019] alpha o >0, α e >0

[0020] α ′ o = α o - α e θ oe β e > 0 , α ′ e = α ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com