Artificial board VOC (Volatile Organic Compounds) releasing cabin capable of guaranteeing limit value of background gas concentration of cabin body

A technology of background gas and release chamber, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve problems such as the influence of experimental results and the gas background concentration not meeting the requirements, and achieve the effects of low cost, easy processing, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

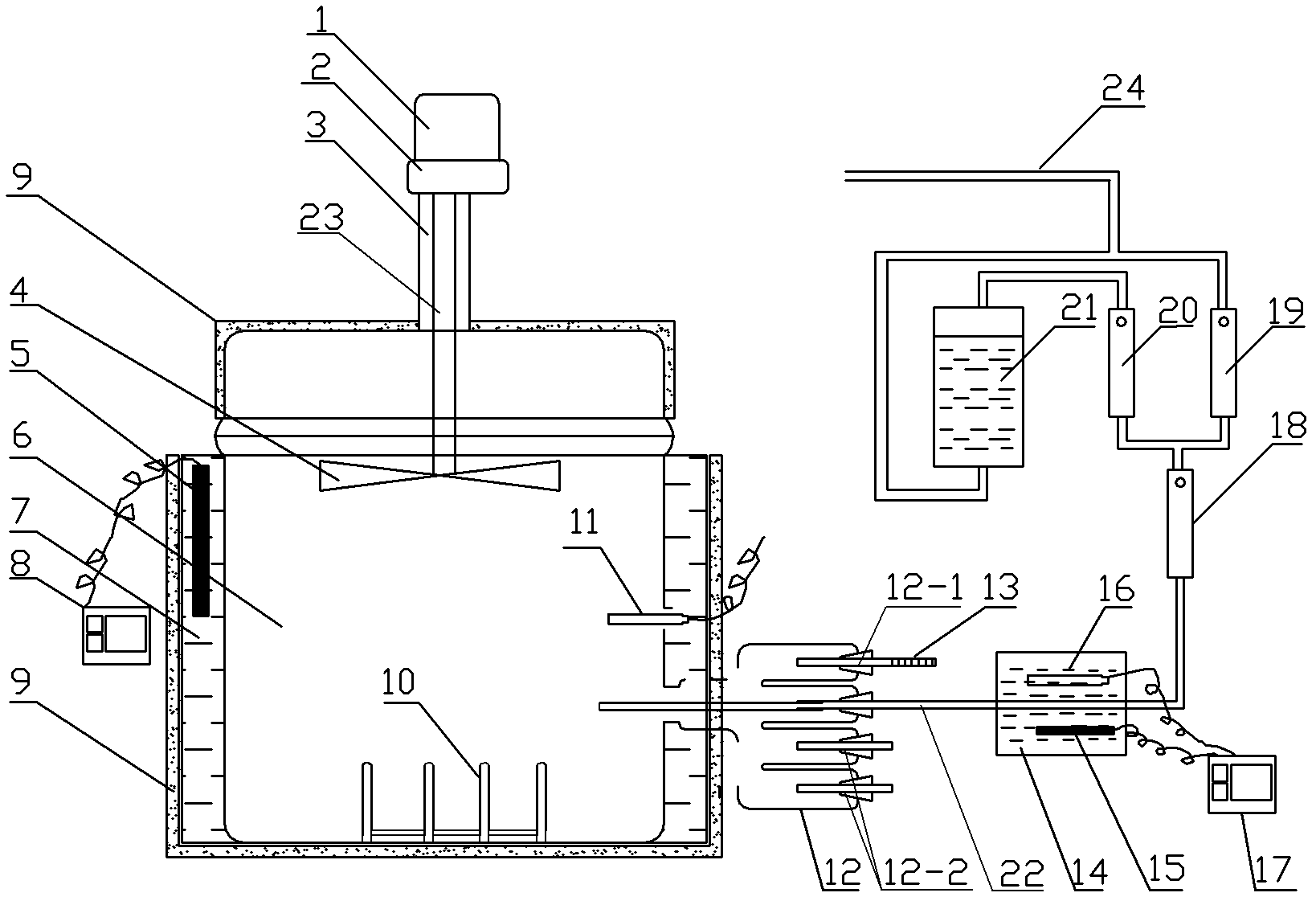

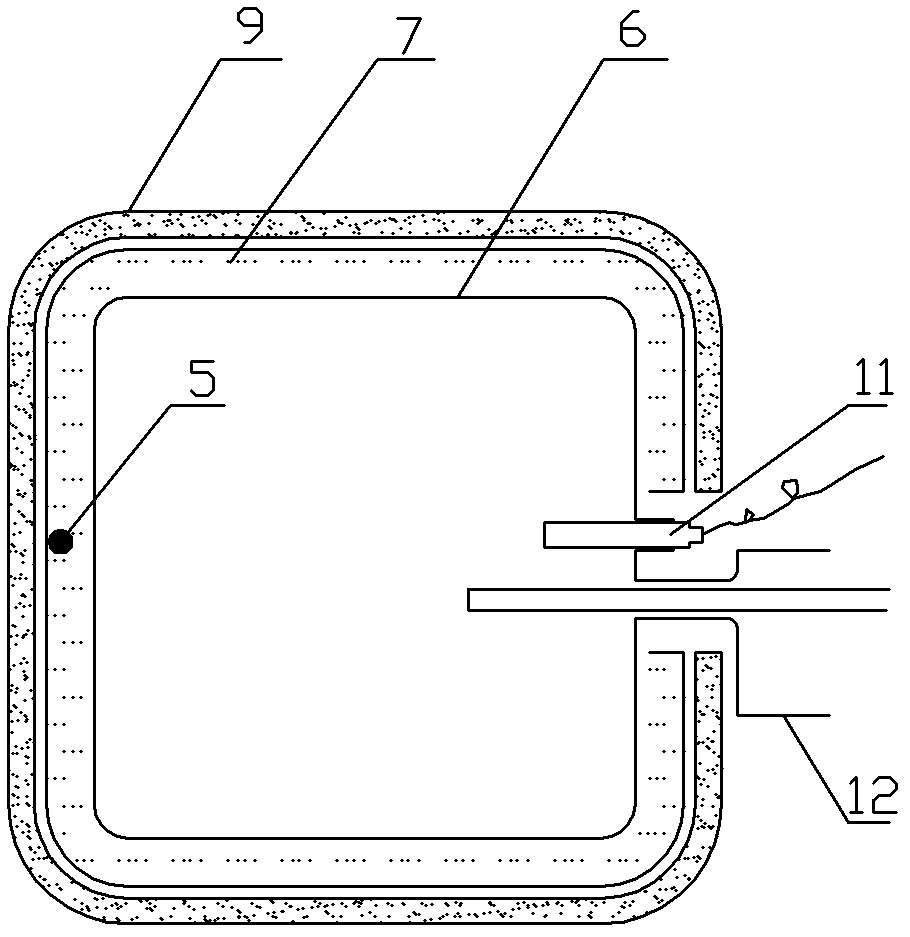

[0010] Specific implementation mode one: combine Figure 1-Figure 3 Describe this embodiment, the release chamber of this embodiment includes a motor 1, a reduction box 2, a stainless steel fan 4, a first electric heating rod 5, a cabin body 6, a first water bath glass cover 7, a first temperature and humidity sensor control Device 8, insulation layer 9, stainless steel bracket 10, first temperature and humidity sensor probe 11, airtight glass cover 12, sampling tube 13, total flow meter 18, second flow meter 19, first flow meter 20, water container 21, Glass tube 22, tetrafluoroethylene shaft 23 and nitrogen gas inlet pipe 24;

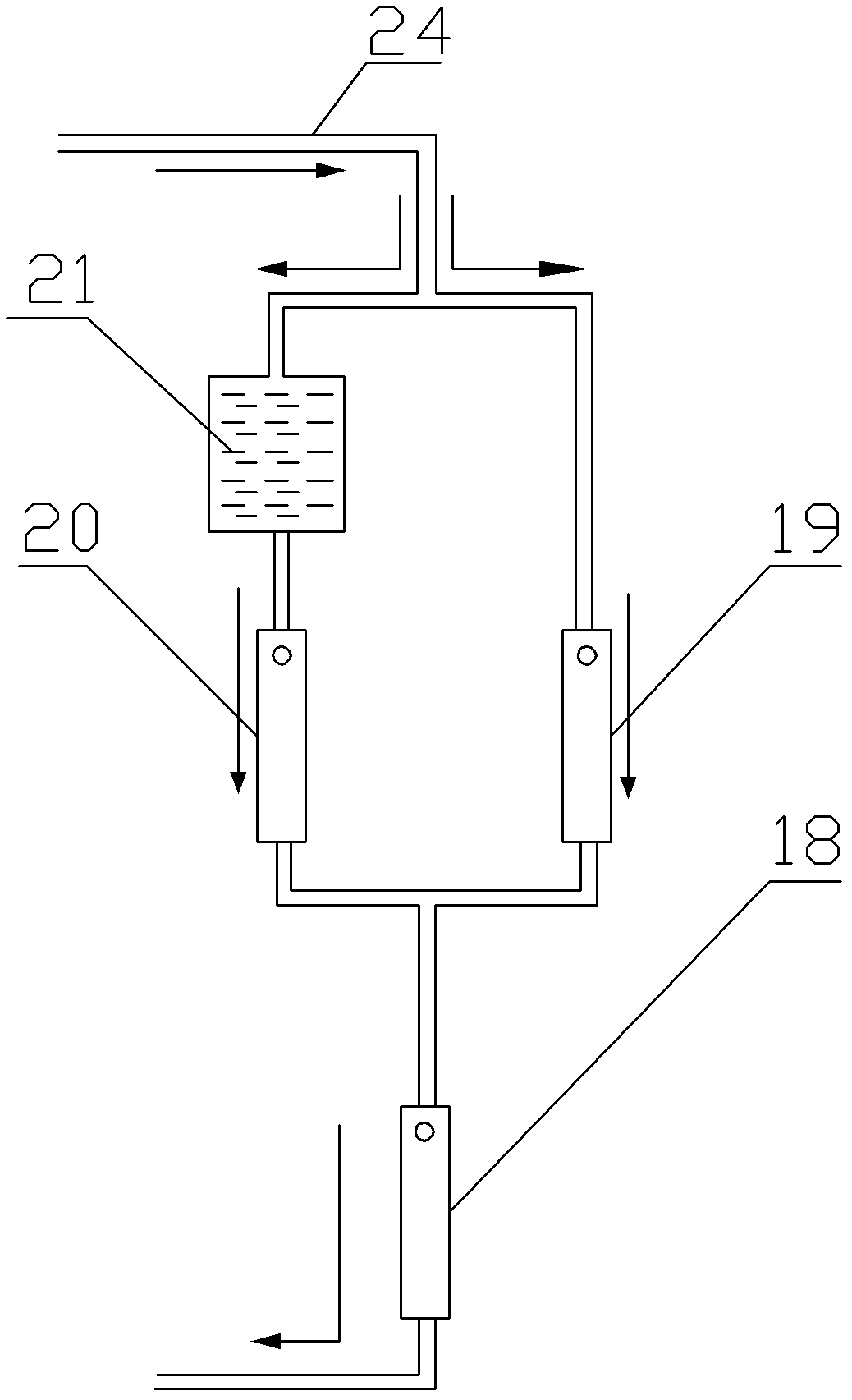

[0011] Nitrogen inlet pipe 24 communicates with water container 21 and second flow meter 19 respectively, and water container 21 communicates with first flow meter 20, and first flow meter 20 and second flow meter 19 are all communicated with total flow meter 18, total The flow meter 18 communicates with one end of the glass tube 22, the other end of...

specific Embodiment approach 2

[0020] Specific implementation mode two: combination figure 1 and figure 2 Describe this embodiment, the insulation layer 9 of this embodiment is a mineral wool layer, and the insulation material mineral wool surrounds the outside of the first water-bath glass cover 7 to ensure the temperature stability of the cabin. Other implementation manners are the same as the specific implementation manner 1.

specific Embodiment approach 3

[0021] Specific implementation mode three: combination figure 1 and figure 2 Describe this embodiment, the release chamber of this embodiment also includes a second water bath glass cover 14, a second electric heating rod 15, a second temperature sensor probe 16 and a second temperature sensing controller 17, the second water bath glass cover 14 is arranged between the airtight glass cover 12 and the total flow meter 18, the glass tube 22 passes through the second water bath glass cover 14, and the second water bath glass cover 14 is provided with a second electric heating rod 15 and a second temperature sensor probe 16, The second electric heating rod 15 and the second temperature sensor probe 16 are all electrically connected with the second temperature sensing controller 17. Before the nitrogen with a certain humidity enters the cabin body 6, it is first heated by a water bath to reach the temperature required for the experiment. The device is controlled by a second tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com