Device and method for recognizing number of cast workpiece scanned by laser

A laser scanning and casting technology, applied in character and pattern recognition, computer parts, instruments, etc., can solve problems such as being only suitable for general printed matter or handwritten text, not suitable for use, and achieve a high degree of automation, high speed, The effect of high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

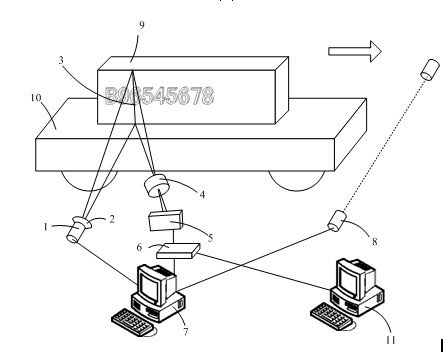

[0048] The present invention will be further described below in conjunction with drawings and embodiments.

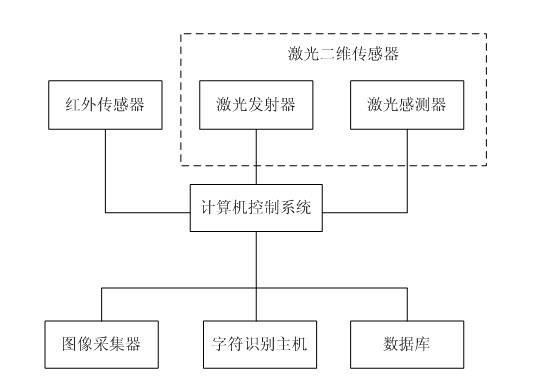

[0049] A laser scanning casting workpiece number identification device, which includes an infrared sensor, a laser two-dimensional scanning sensor, an image collector, a character recognition host, a computer control system and a database,

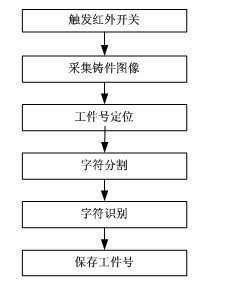

[0050] An infrared sensor is used to monitor whether the casting enters the detection area, and sends a discrimination signal to the computer control system that the casting enters the detection area;

[0051] The laser two-dimensional scanning sensor scans the workpiece number on the casting under the control of the computer control system;

[0052] The image collector preprocesses the workpiece number scanned by the laser two-dimensional scanning sensor, and obtains a binarized workpiece number image;

[0053] The character recognition host uses the pattern recognition algorithm to recognize the workpiece number image processed b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com