Digital hopper-balance checker

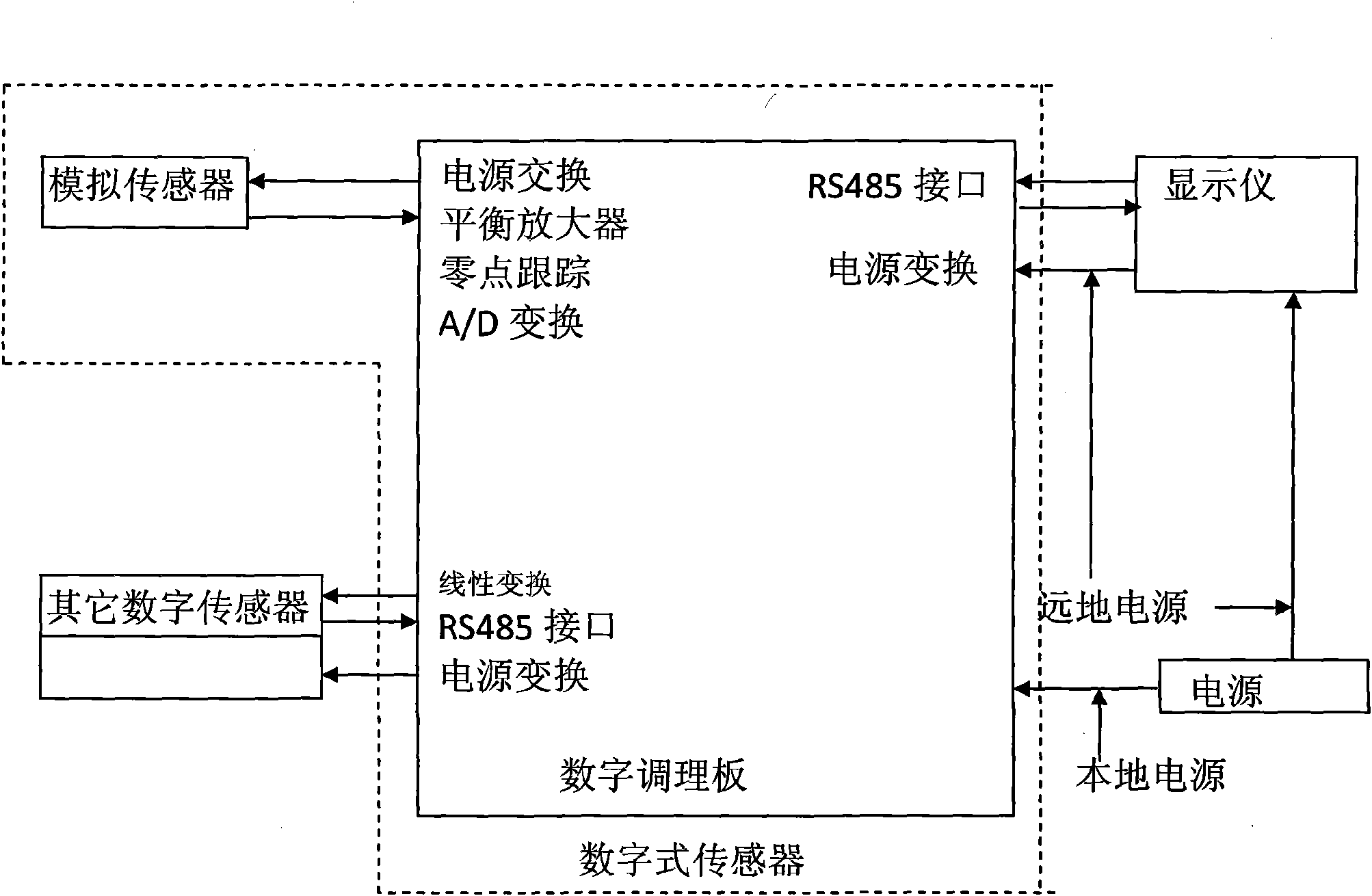

A calibration device and digital technology, applied in the field of metrology and detection, can solve the problems of difficult monitoring of the force condition of the sensor, inconvenience in transmission, reception and data processing, weak anti-interference ability, etc. Easy environmental interference, good signal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

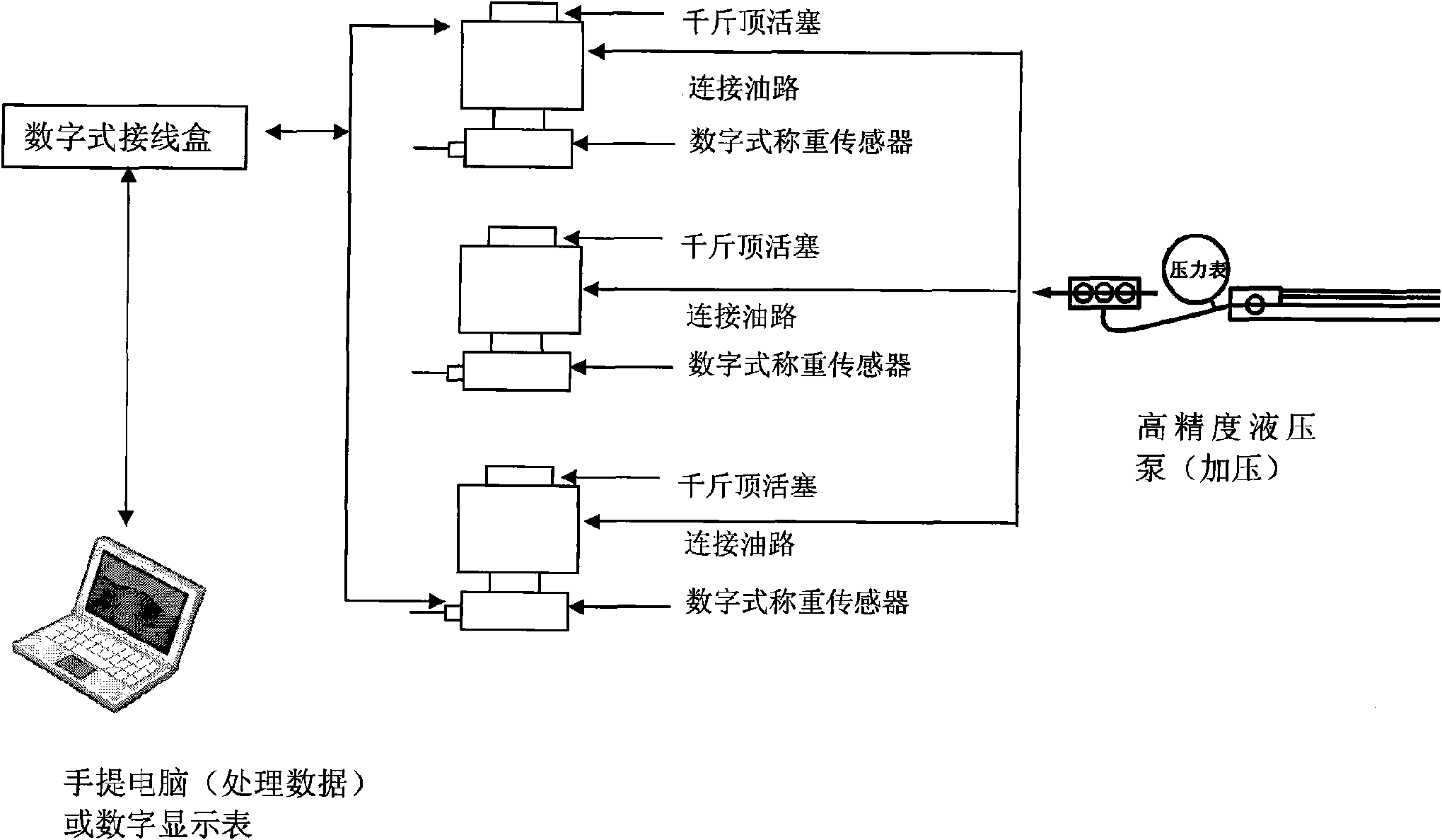

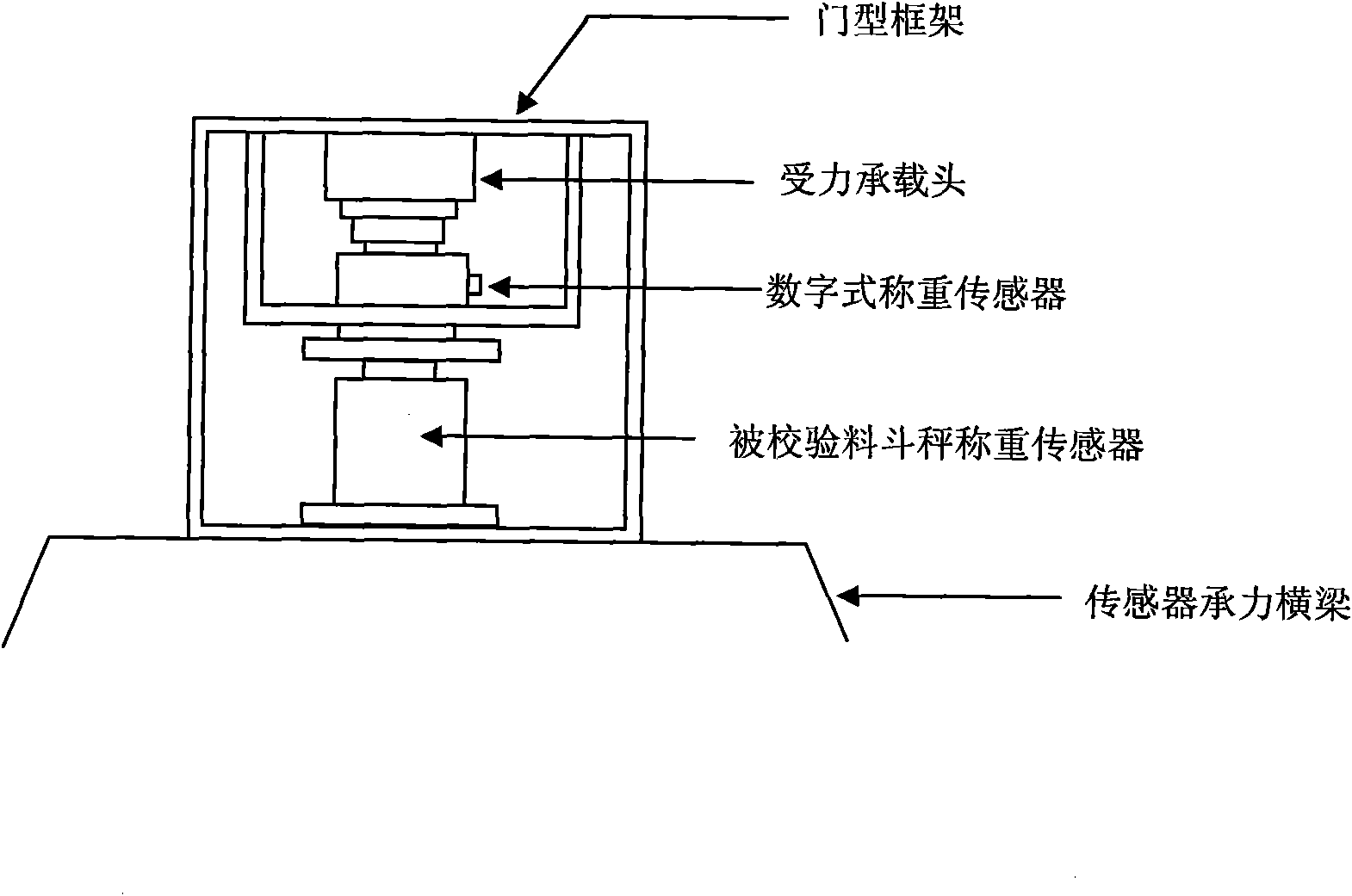

[0012] Such as figure 2 , image 3 As shown, the present invention includes a portal frame, a high-precision hydraulic pump, a voltage stabilizing energy storage device, a jack, a force bearing head and a weighing sensor of a hopper scale to be verified. A digital load cell is installed vertically between the load bearing head and the load cell of the hopper scale to be verified, and the load cell of the hopper scale to be verified and the digital load cell are placed on the load-bearing beam of the sensor A plurality of the digital load cells are connected to a digital junction box, and the digital junction box transmits the digital signal to the computer for processing through the bus, and the computer is equipped with a computer for calculating and comparing the digital signal Analytical digital hopper scale calibration software.

[0013] The pressure source of this device is provided by a high-precision hydraulic pump. After the zero adjustment is completed, the hydraul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com