Lamination-recombination passive film used for front surface of single-crystalline-silicon solar cell

A solar cell and front surface technology, which is applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of unsatisfactory passivation effect, poor optical matching performance of anti-reflection film and packaging materials, etc., and achieve good optical matching Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

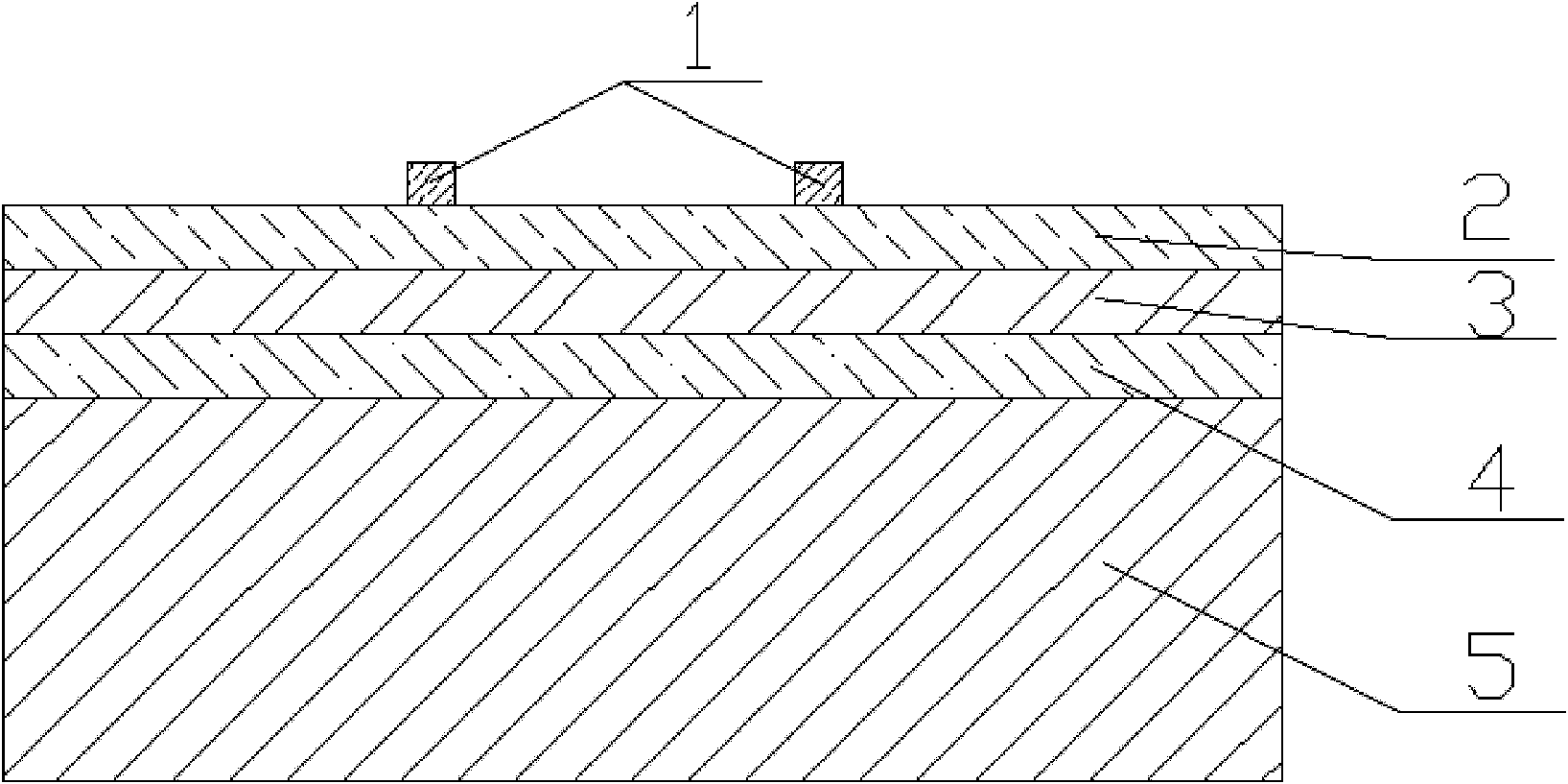

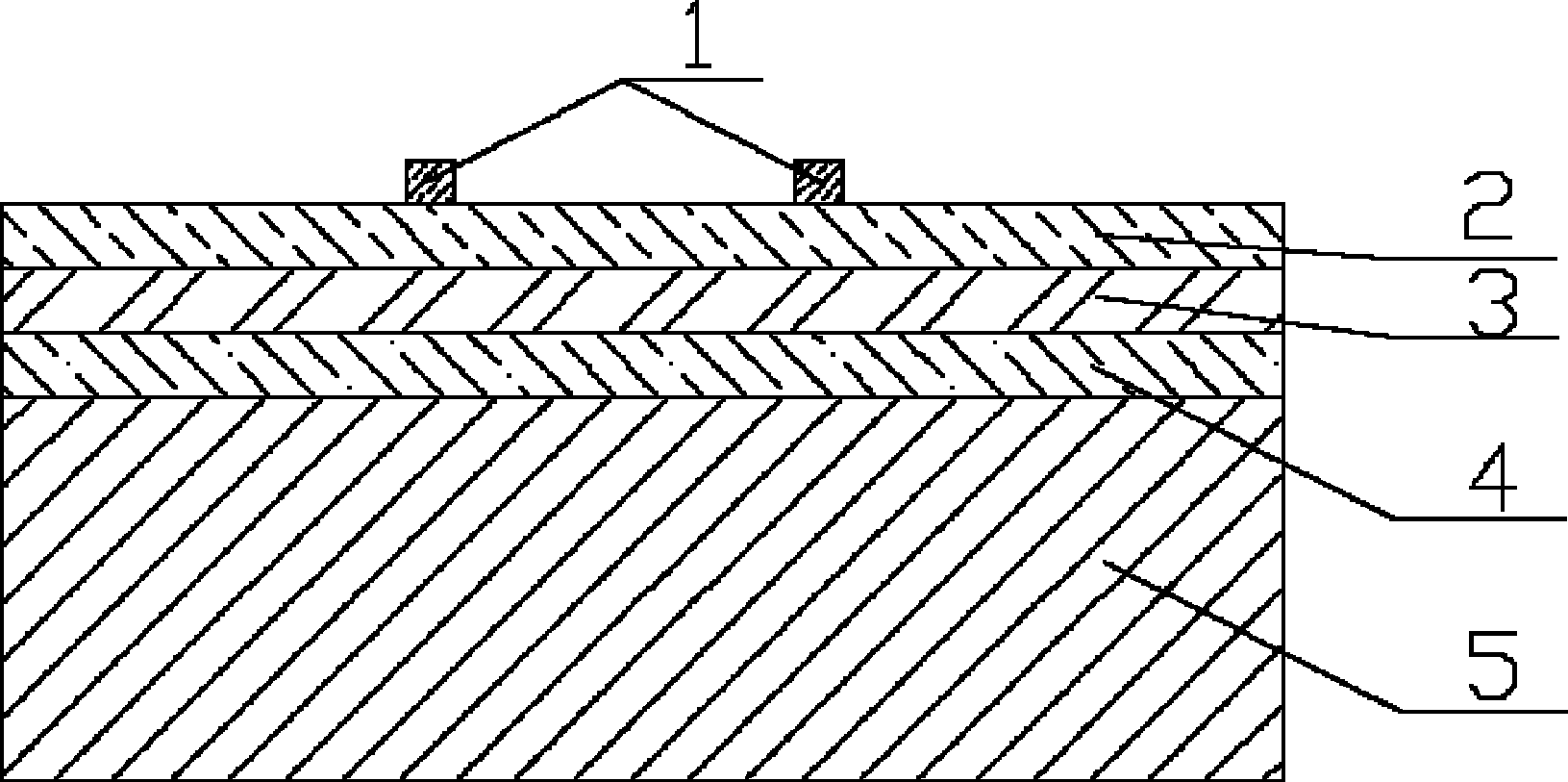

[0021] Such as figure 1 As shown, a laminated composite passivation film for the front surface of a monocrystalline silicon solar cell, on the front surface of the monocrystalline silicon substrate 5 of the solar cell, a silicon oxide film 4 and a hydrogenated amorphous silicon film 3 are sequentially arranged from the inside to the outside And a silicon nitride film 2; a printed electrode 1 is arranged on the silicon nitride film 2.

[0022] The silicon oxide film 4 of the present invention is a silicon dioxide layer with a thickness of 40-50 nm; the hydrogenated amorphous silicon film 3 has a thickness of 15-20 nm; and the silicon nitride film 2 has a thickness of 60-70 nm.

[0023] The silicon oxide film of the present invention makes the surface state density of the cell sheet the same order of magnitude as the atomic density of silicon, the hydrog...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com