Intelligent inter-row mechanical weeding machine

A weeding machine and row-to-row technology, applied in the field of intelligent inter-row mechanical weeding machines, can solve problems such as high price, crop and soil environmental pollution, uncontrollable weeds, etc., achieving low precision requirements and reducing dependence. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

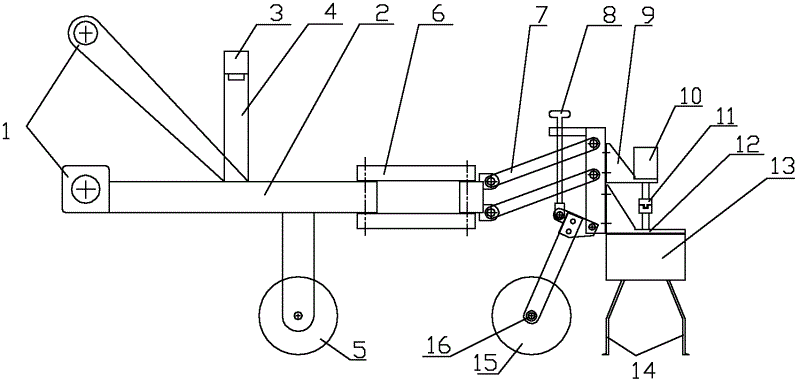

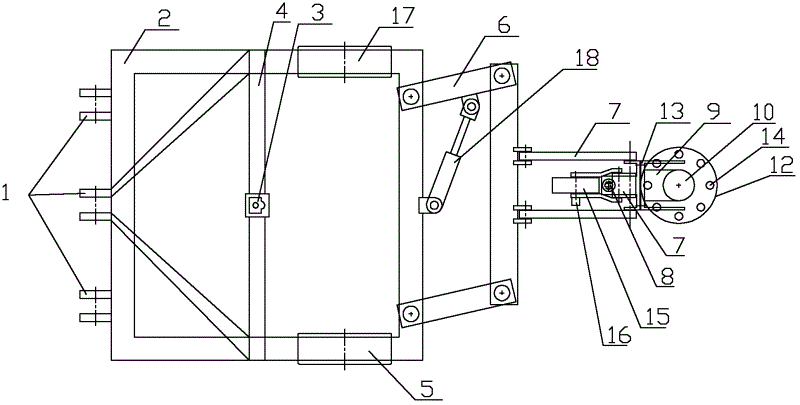

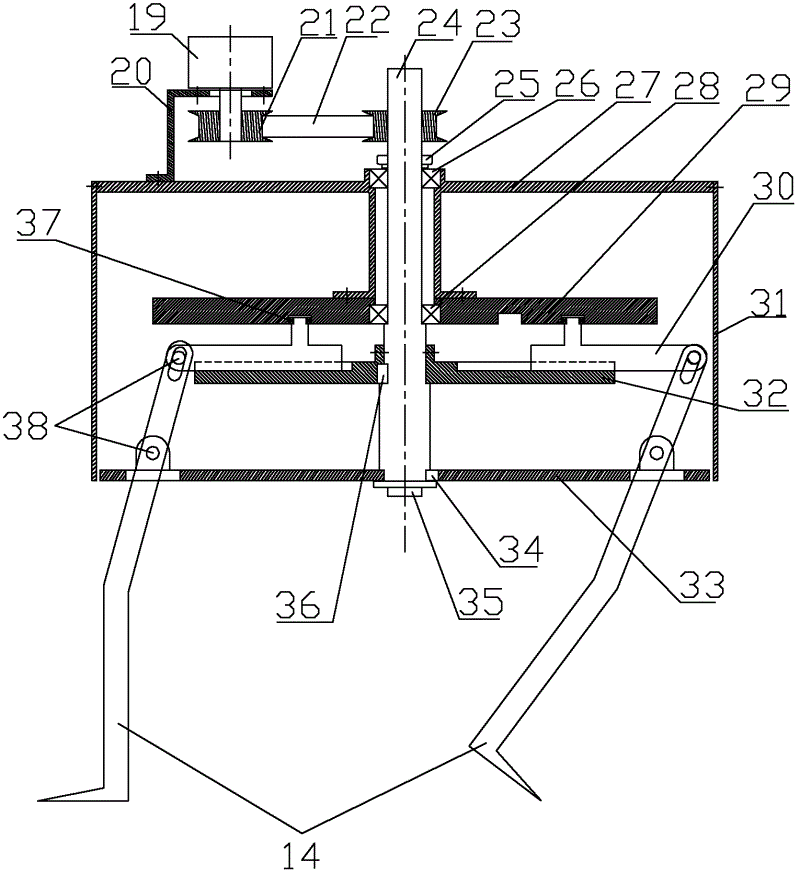

[0034] Such as Figure 1 to Figure 10 As shown, the present embodiment is an intelligent inter-row mechanical weeder, including a frame, a crop recognition machine vision system, a traverse compensation control system, a depth adjustment system and an inter-row weeding device.

[0035] One end of the frame 2 is fixed with a three-point suspension mechanism 1, and the weeder is connected with the three-point suspension mechanism of the agricultural tractor through the three-point suspension mechanism 1, and the weeder is moved forward by the agricultural tractor. Left and right wheels 5 and right wheels 17 are arranged on the left and right sides of the frame 2 respectively.

[0036] The crop recognition machine vision system includes a camera and an image processor 3. The image processor acquires crop images from the camera, and provides crop information to the lateral movement compensation control system and inter-row weeding device after image processing, and the camera and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com