Water chestnut collecting vessel

A water chestnut and harvesting tooth technology, which is applied to harvesters, digging harvesters, and rigid working parts, can solve the problems of high labor intensity and low production efficiency, and achieve the effect of reducing labor intensity and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

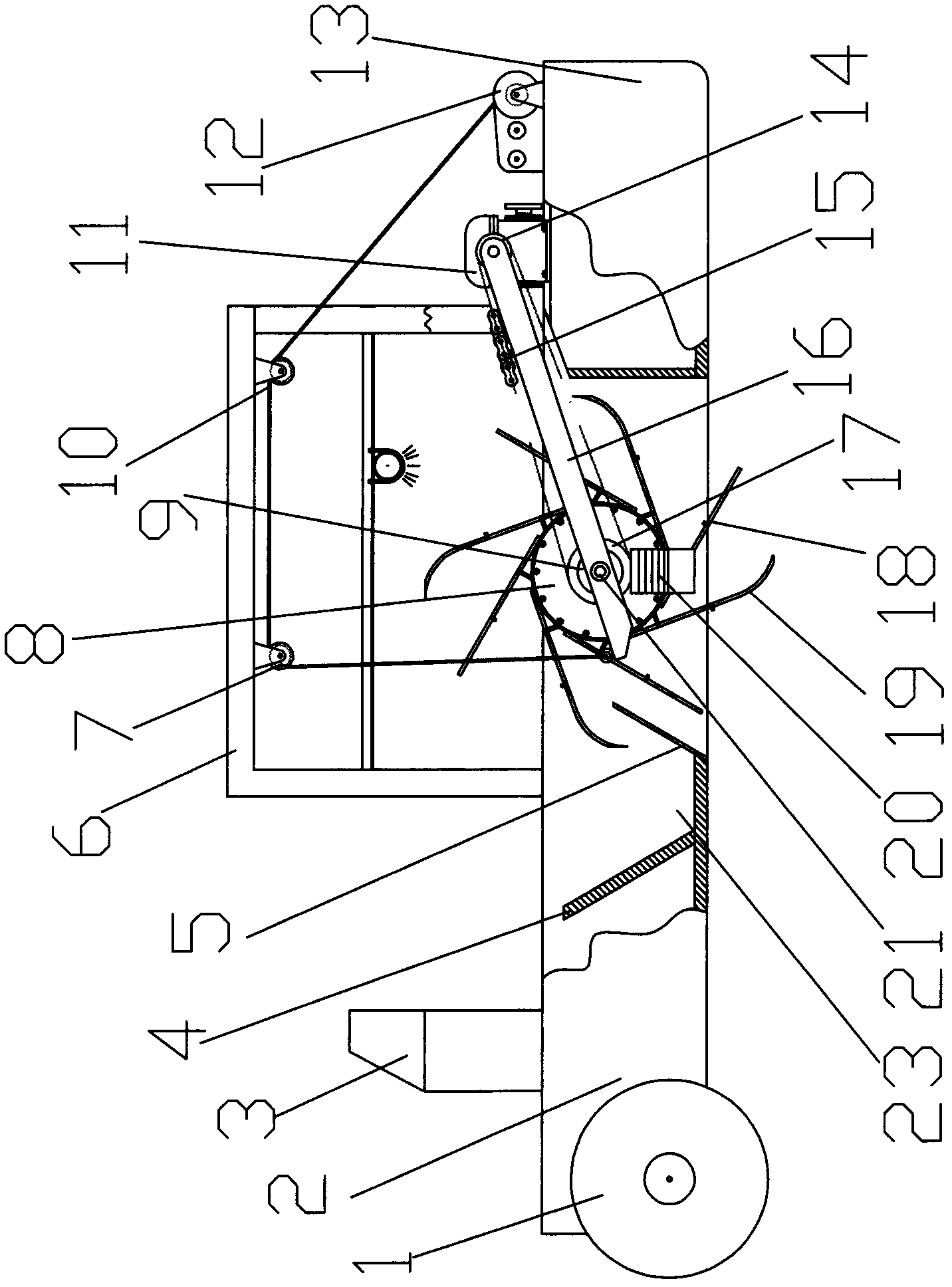

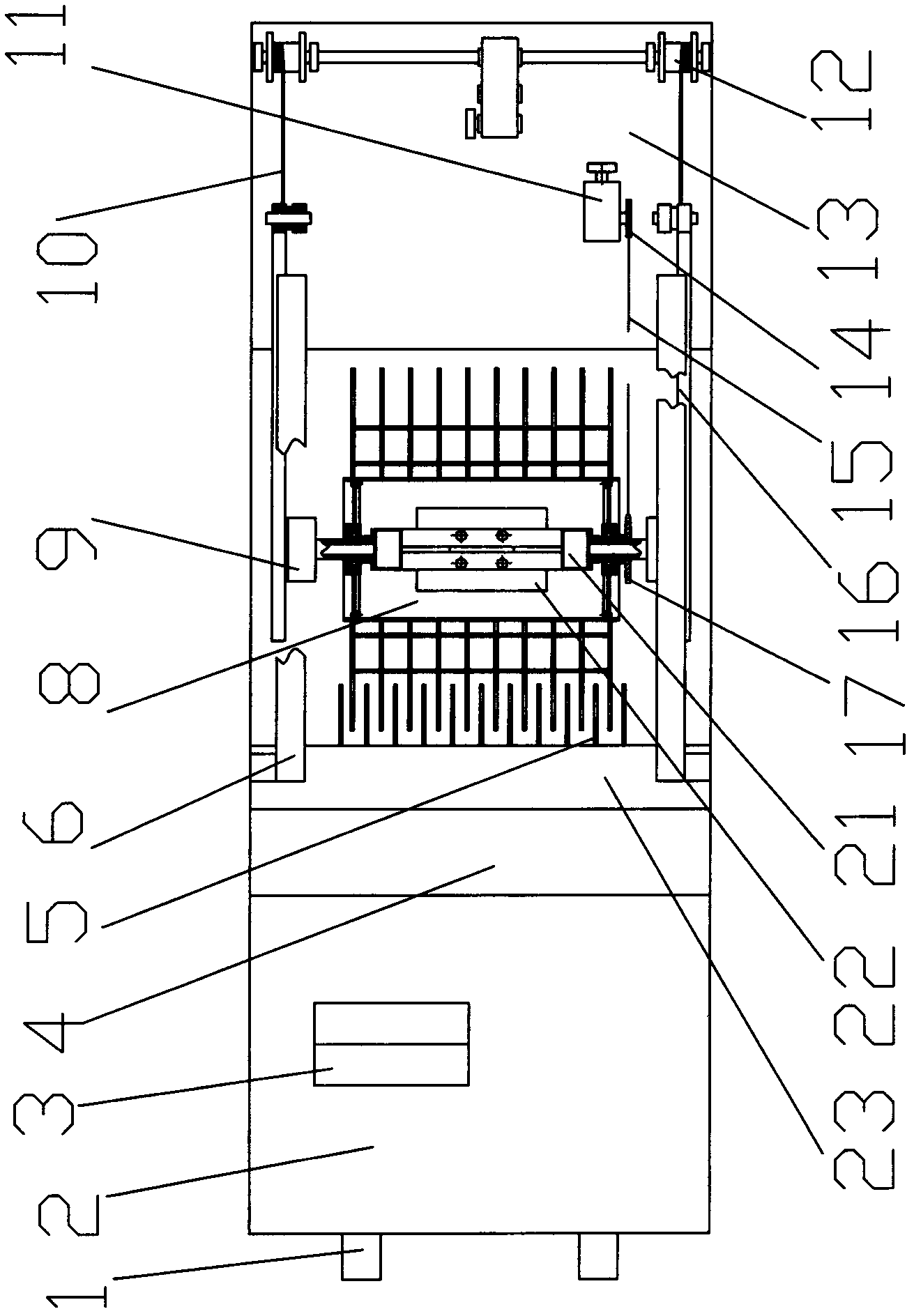

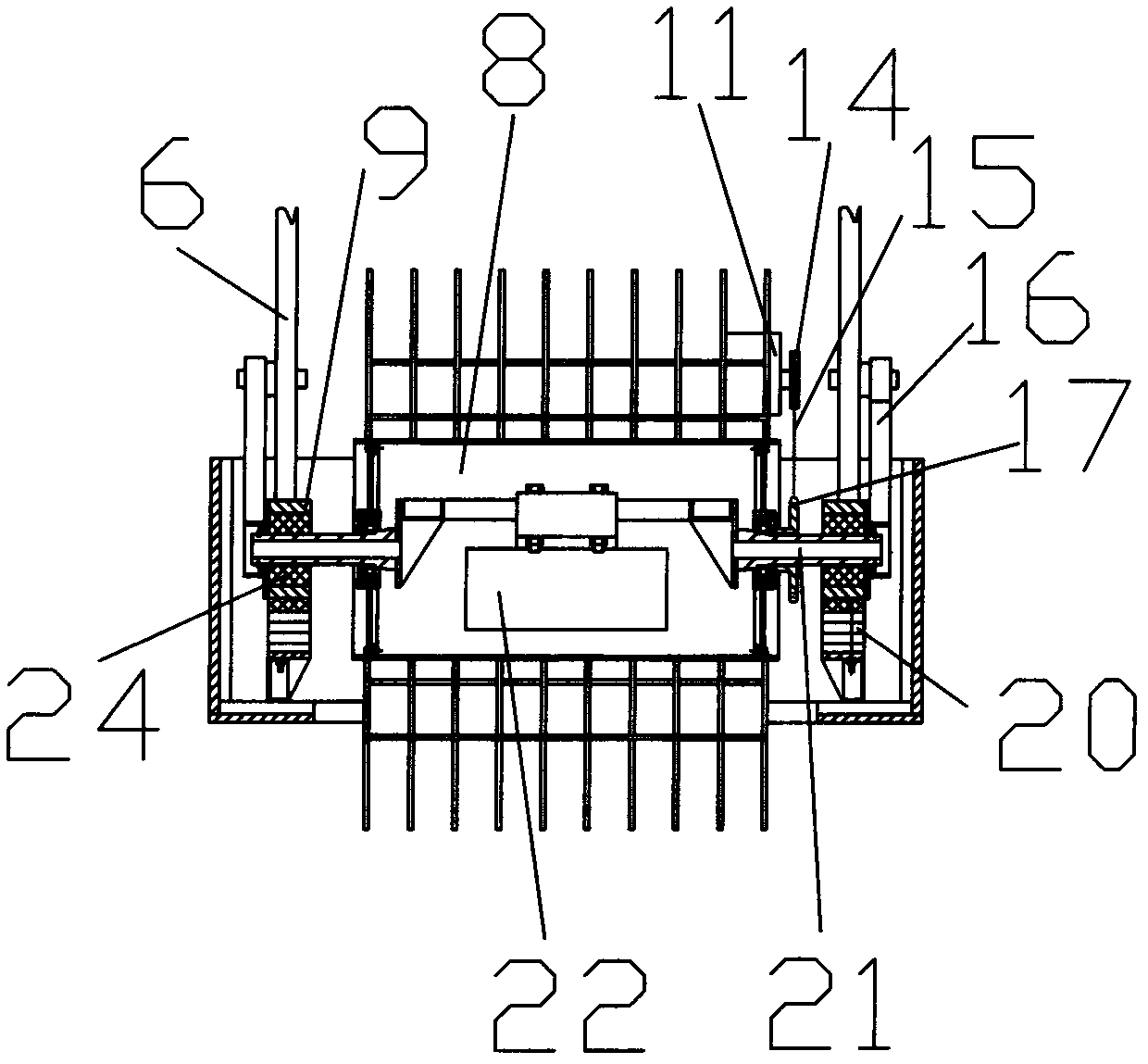

[0018] A harvesting drum 8 that can vibrate and rotate is installed in the middle of the hull whose horizontal projection is a rectangle and the height of the side is less than 1000 mm. Two driving wheels 1 are installed at the tail of the hull, and a double-barrel winch 12 and a speed reducer are installed on the deck at the front of the hull. 11. An engine is installed in the front cabin 13, which is not drawn in the figure. Under the control of the console 3 arranged on the rear deck, the hull slides on the water chestnut planting ground with a water depth of less than 200mm, and the harvesting on the harvesting drum 8 Teeth 19 and vibrating teeth 18 are inserted into the soil and are driven by the vibrator 22 to liquefy the soil. The liquefied soil leaks out from the gaps between the harvesting teeth 19, and the water chestnut bulbs are piled up on the harvesting teeth 19, and along with the harvesting drum 8 The rotation of the water chestnut is taken out of the water surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com