Processing technique for Guire No. 1 green tea

A processing technology, the technology of Guire, is applied in the field of processing technology of Guire No. 1 green tea, to achieve the effect of straight appearance, long-lasting chestnut aroma, mellow and sweet aftertaste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

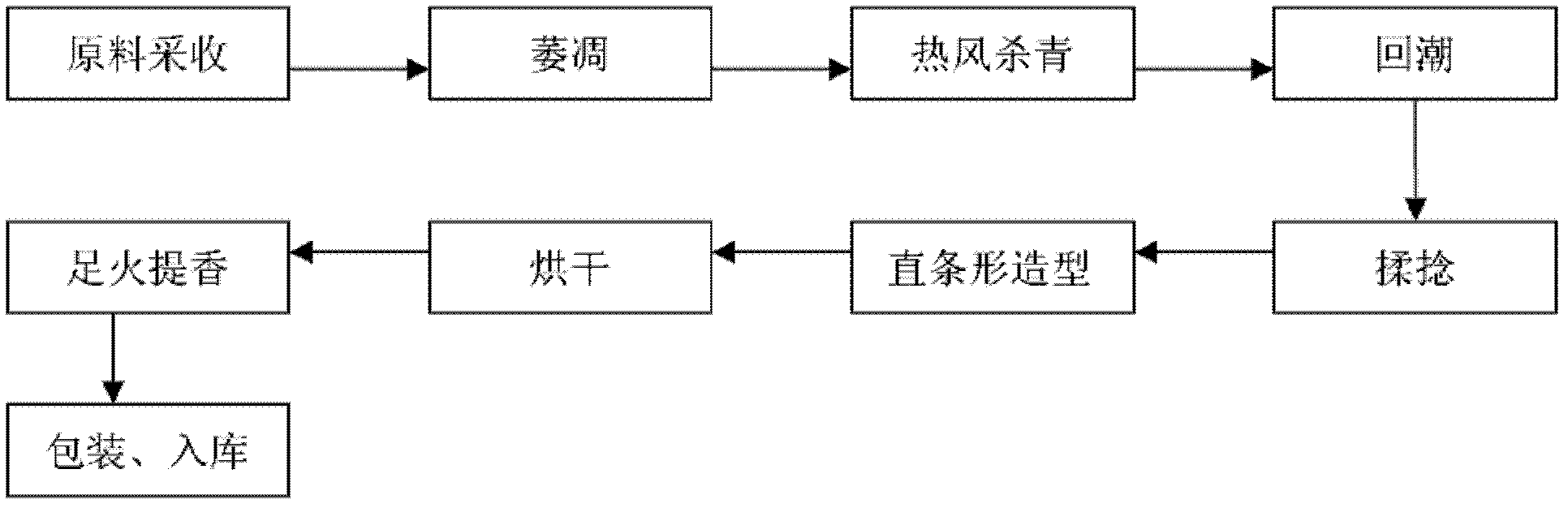

Image

Examples

Embodiment 1

[0025] (1) Harvesting of raw materials The fresh leaves of one bud and one leaf Guire No. 1 tea tree are picked as raw materials;

[0026] (2) Withering Spread the raw materials of the fresh leaves in step (1) evenly on the dustpan and wither until the leaves are soft and the tender stems are broken continuously, the leaves lose their luster, the leaves are dark green, the green air is emitted, and the fragrance is released. Flip by hand, wither and lose 18% of water;

[0027] (3) Hot-air de-enzyming The Guire No. 1 withered and dehydrated raw material obtained in step (2) is de-enzymed using a 6CCR-75 type continuous hot-air de-enzyming machine. The hot-air de-enzyming temperature is 280° C. The leaf color turns dark green, the green air disappears, and the fragrance is revealed;

[0028] (4) Moisturize the Guire No. 1 green leaves treated in step (3) to cool and regain moisture, so that the moisture in the tea leaves can be redistributed to facilitate the tea leaves to be s...

Embodiment 2

[0035] Wither and lose water to 20%, the temperature of hot air finishing is 300 DEG C, gently kneaded for 18 minutes, 45 DEG C of strip temperature, 10 minutes of time, other is substantially the same as embodiment 1.

Embodiment 3

[0037] Wither and lose water to 22%, the temperature of hot air finishing is 320 DEG C, knead gently for 20 minutes, strip temperature is 50 DEG C, the time is 9 minutes, and others are basically the same as embodiment 1.

[0038] The Guire No. 1 green tea produced in Examples 1 to 3 has a straight appearance, emerald green and oily color, bright yellow-green soup, mellow and sweet aftertaste, long-lasting chestnut fragrance, and even green leaves at the bottom of the leaves.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com