Two-step preparation method for biomass material-based high-performance adsorbent

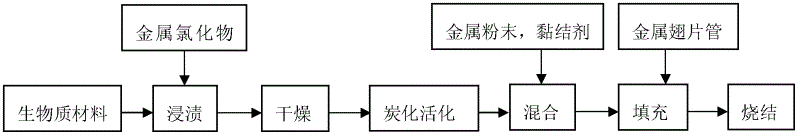

A biomass material and adsorbent technology, which is applied in the field of two-step preparation of high-performance adsorbents, can solve the problems of low metal chloride content, low thermal conductivity, and influence on mass transfer, etc., and achieves high adsorption component content and contact heat. The effect of small resistance and high adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Carbonization activated pore making: the raw materials used are: calcium chloride, fir sawdust, deionized water, and calcium chloride is used as the adsorbent. Firstly Chinese fir is crushed into 20 mesh spherical particles, then an aqueous solution of calcium chloride is prepared, the mass concentration is 40%, the mass ratio of calcium chloride and Chinese fir sawdust is 4: 1, the Chinese fir sawdust is immersed in the aqueous calcium chloride solution, and the immersion time is 24 hours. The mixture of fir sawdust and calcium chloride was filtered out, dried at 120°C for 24 hours, and then put into a tube furnace for carbonization and activation to prepare a composite adsorbent. The carbonization temperature is 500°C, the carbonization time is 2 hours, the carbonization atmosphere is nitrogen, the activation temperature is 500°C, the activation time is 2 hours, and the activation atmosphere is carbon dioxide.

[0028] (2) Filling: Mix the composite adsorbent pre...

Embodiment 2

[0031] (1) Carbonization activated pore-forming: the raw materials used are: barium chloride, corn cob, deionized water, and barium chloride is used as the adsorbent. First corn cobs are crushed into 10 mesh spherical particles, then barium chloride aqueous solution is prepared, the mass concentration is 30%, the mass ratio of barium chloride and corn cobs is 3: 1, the corn cobs are immersed in the barium chloride aqueous solution, the immersion time for 24 hours. The mixture of corncobs and barium chloride was filtered out, dried at 120°C for 24 hours, and then the mixture was carbonized and activated in a tube furnace to prepare a composite adsorbent. The carbonization temperature is 650°C, the carbonization time is 1 hour, and the carbonization atmosphere is argon. The activation temperature is 650°C, the activation time is 1 hour, and the activation atmosphere is carbon dioxide.

[0032](2) Filling: Mix the composite adsorbent prepared after carbonization and activation ...

Embodiment 3

[0035] (1) Activated pore formation by carbonization: The raw materials used are: strontium chloride, straw, deionized water, and strontium chloride is used as the adsorbent. First, the straw is crushed into 30-mesh spherical particles, then an aqueous solution of strontium chloride is prepared, the mass concentration is 50%, the mass ratio of strontium chloride and straw is 6:1, and the straw is immersed in the aqueous solution of strontium chloride for 24 hours . The mixture of straw and strontium chloride was filtered out, dried at 120°C for 24 hours, and then the mixture was carbonized and activated in a tube furnace to prepare a composite adsorbent. The carbonization temperature is 450°C, the carbonization time is 3 hours, and the carbonization atmosphere is vacuum. The activation temperature is 450°C, the activation time is 3 hours, and the activation atmosphere is carbon dioxide.

[0036] (2) Filling: Mix the composite adsorbent prepared after carbonization and activa...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap